Stringent regulatory norms imply potentially higher liability for any production errors. Quality control is an important aspect of the pharmaceutical industry and has been one of the biggest concerns for manufacturers.

Latest technologies like IoT, deep learning, and artificial intelligence provide innovative methods for quality validation. One common way adopted by pharmaceutical companies to improve quality control is using machine vision systems.

The pharmaceutical industry was amongst the early adopters of machine vision to ensure product safety and integrity. Machine vision plays a crucial role to deliver high-quality products consistently. Since its early stage, this technology has witnessed significant advances and can deliver productivity gains with specific applications.

Applications of Machine Vision in the Pharmaceutical Industry

Shipping, production, and data processing are some common applications for pharmaceutical machine vision technology.

Typical usage includes labelling, code validation, cap integrity, package integrity, safety seal, fill levels,

contamination, and surface defects.

Quality control of packaging and products

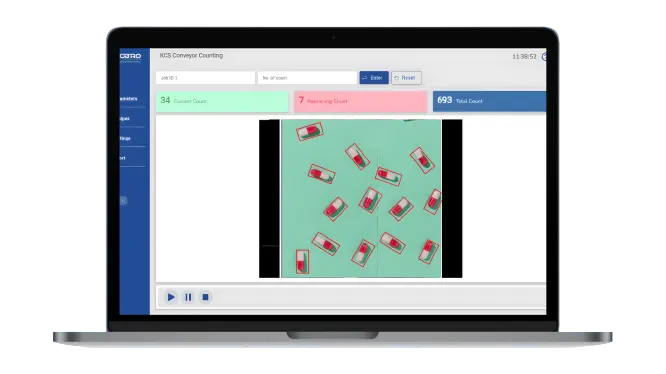

This is one of the most prominent applications for vision systems for inspection in this industry. The use of automated inspection systems ranges from condition and quantity detection to the inspection of products for defects like printed instructions, label readability, and more. Some problems that can be addressed include:

- Validation of labels for bar codes and product information

- Counting the number of pills contained in each package

- Quality control of secondary items, such as instruction leaflets

- Package inspection for damage and quality control

- Inspection of each tablet/pill for dimensional accuracy and damages

Quality control using automated inspection systems can also include detecting childproof caps, plastic wrappers on the caps, correct boxes, and other packaging aspects. A high-tech camera in the production line can inspect every product and package to identify defects. This allows companies to identify defective products or packaging early and reduce wastage. Additionally, lesser defective products are shipped, thereby saving on recall expenses. Automated vision systems thereby improve production efficiency and enhance profits for pharmaceutical companies.

Product traceability and shipment tracking

For accountability and compliance, it is important to be able to track all drugs and other items delivered to various distribution centres and stores. Additionally, tracing products from patients back to the manufacturing company in case of any side effects or defects is crucial. Pharmaceutical companies must provide the required tracking information for all products. Machine vision can be beneficial in consolidating the information and sending it across multiple channels during shipping. Departments like warehouses, distribution centres, and factories can benefit from machine vision technology.

Machine learning can be used to detect information from the bar codes and serial numbers to keep track and prevent counterfeiting. Serial numbers can also trace the manufacturing date and the production line where the products were manufactured, which allows companies to provide the information when required.

Digitalization

Document digitalization and data entry are other applications for machine vision in pharmaceutical industry. Machine learning models for OCR-trained pharmaceutical and clinical forms could extract and recognize important data and send these to a database. This can significantly reduce manual efforts, especially for companies that work with a large number of forms comprising information that is used in the future.

Documents like lab notes, clinical trial documents, and medical or clinical records of patients can be digitalized. Patient reports may comprise important information about any side effects of certain medications and their severity, which can provide valuable insight during trials. Digitalization can input all the necessary information, which can contribute to the patients’ health and satisfaction.

As machine vision is adopted more by pharmaceutical companies, the number of niche software to handle specific applications will increase. This technology is important for the industry and can meet the stringent requirements of the regulatory authorities and enhance product quality control. Machine vision technology significantly increases productivity and efficiency in the inspection process and will continue its growth as more pharmaceutical companies adopt this technology.