In Automotive and Metal parts manufacturing applications, quality is always the top concern. Stringent regulatory standards mean high levels of liability for errors in production. Machine vision plays a major role in delivering consistent high-quality products in the metal and automotive industry, but machine vision can also deliver productivity gains, within the confines of high quality demands.

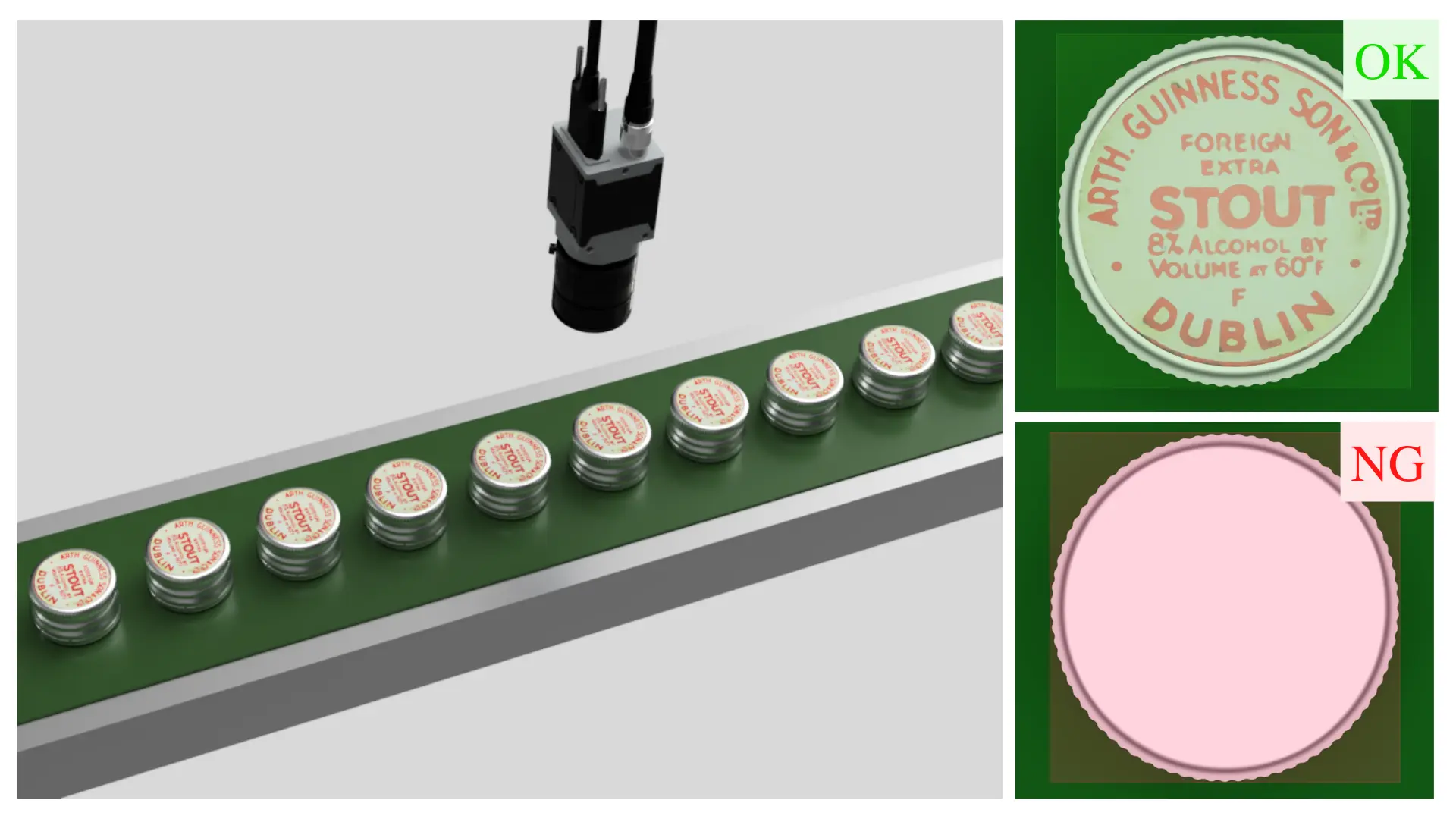

Kiara Vision Platform is an AI-Vision and Machine Learning based industrial solution which enables accurate counting, automatic sorting and high speeds inspection. An industry 4.0 solution, which is developed to solve any problem of the metal and automotive industry.

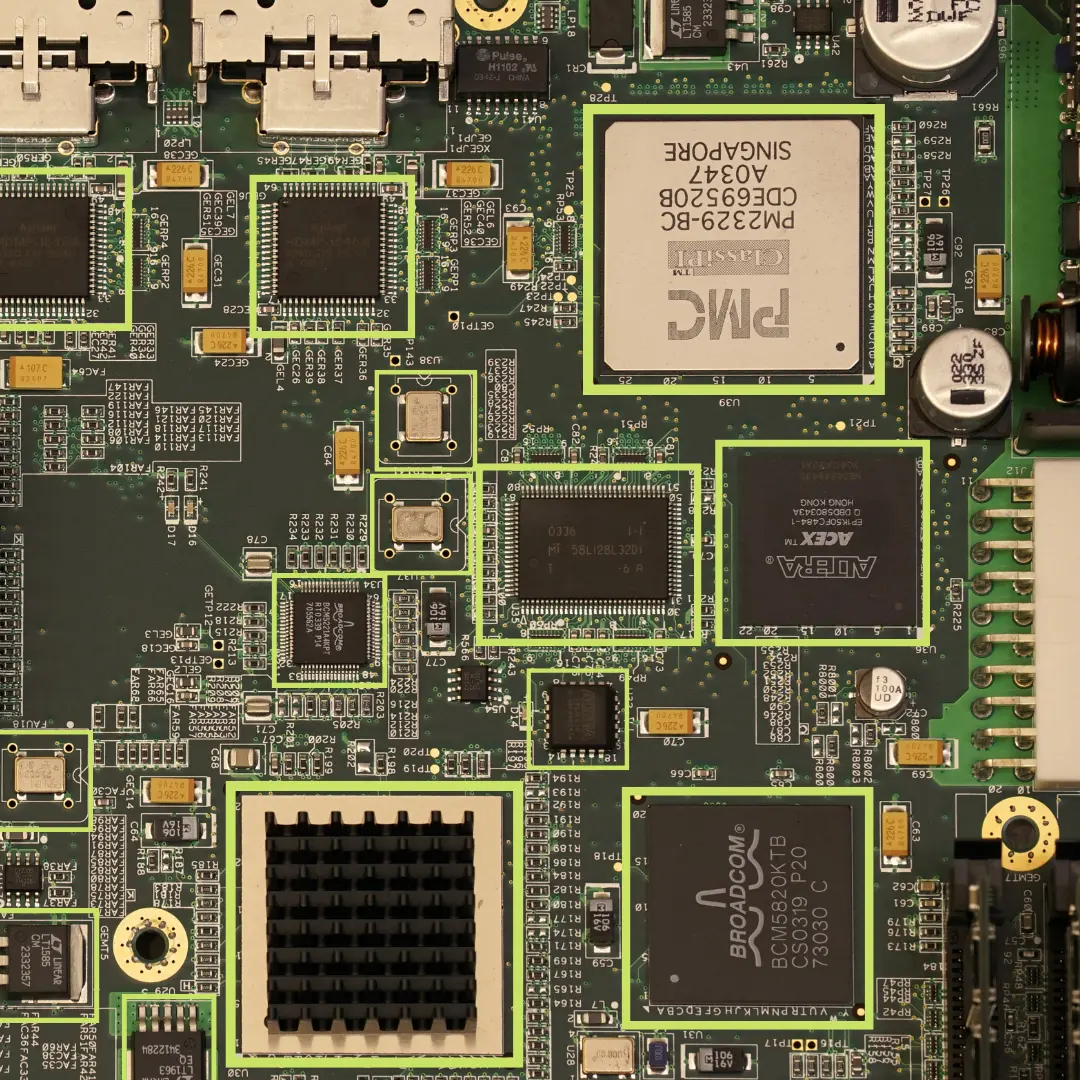

Component Inspection

Component Inspection

Small, sophisticated components are used to create compact electronic devices. But manual inspection of such components can be erroneous and time-consuming. AI-Vision enables detailed inspection of each small component.

Assembly Verification

Assembly Verification

Proper Assembly plays a crucial role in the functioning of any device. Manufacturers put the most effort in assembly verification to make sure everything goes smooth. Kiara Vision Platform achieves all the necessary standards of Assembly Verification with AI and Machine Vision

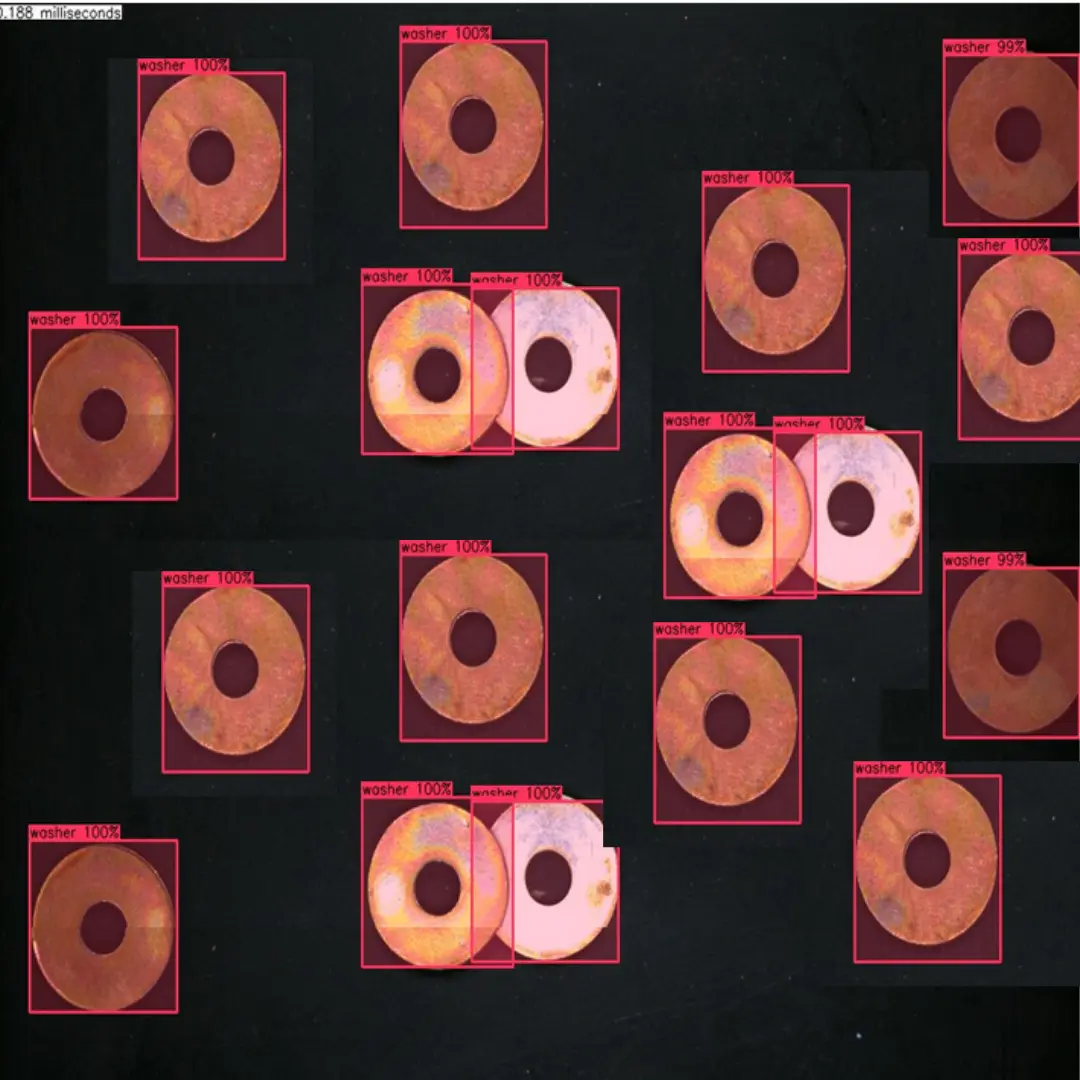

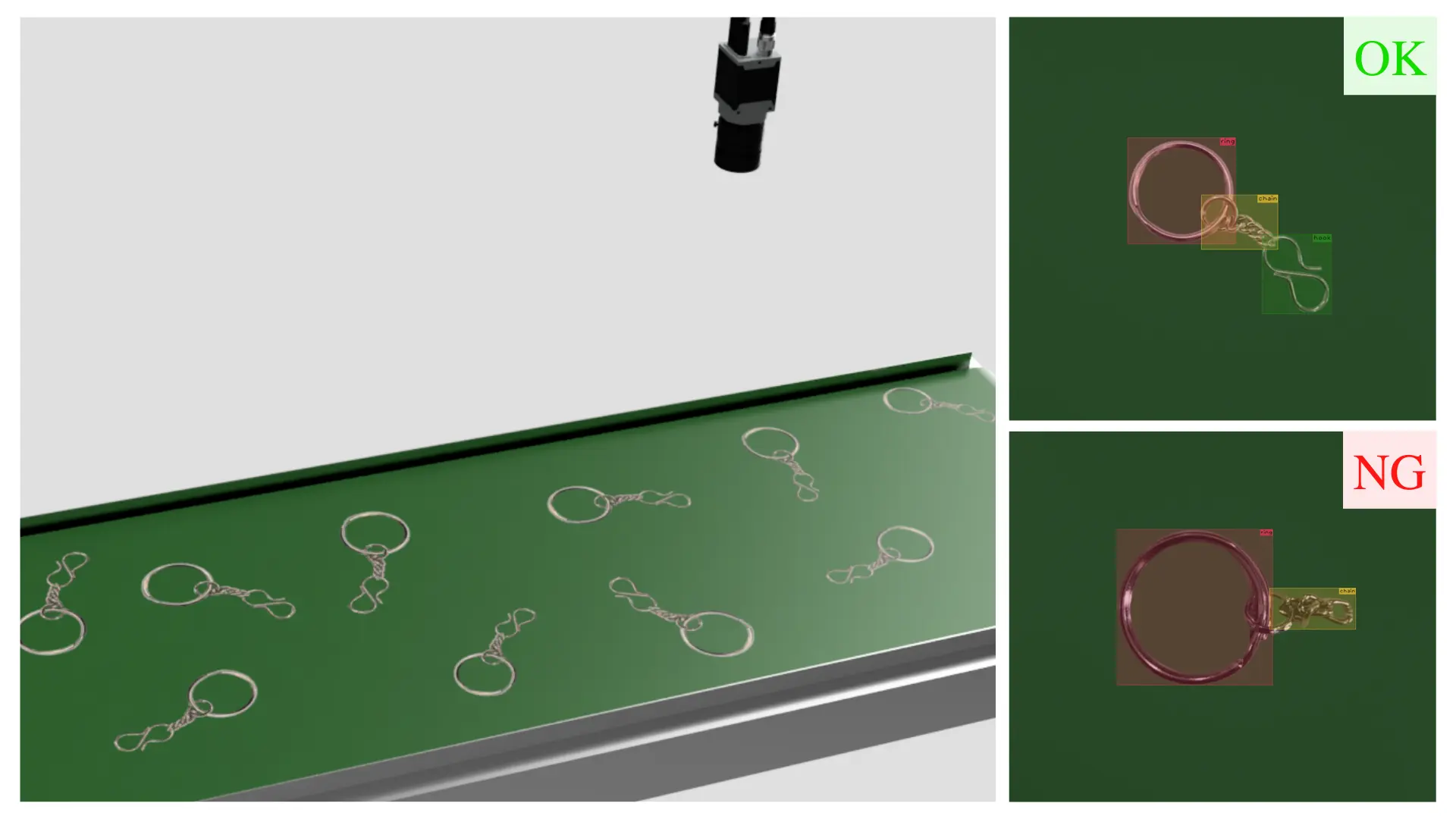

Sorting and Classification

Sorting and Classification

Often, a variety of parts need to be classified, sorted or identified and counted differently in manufacturing lines. Such operations are not possible with manual and traditional measures with 100% accuracy. Kiara Vision Platform uses AI-Vision technology for precise and smooth flow of such operations.

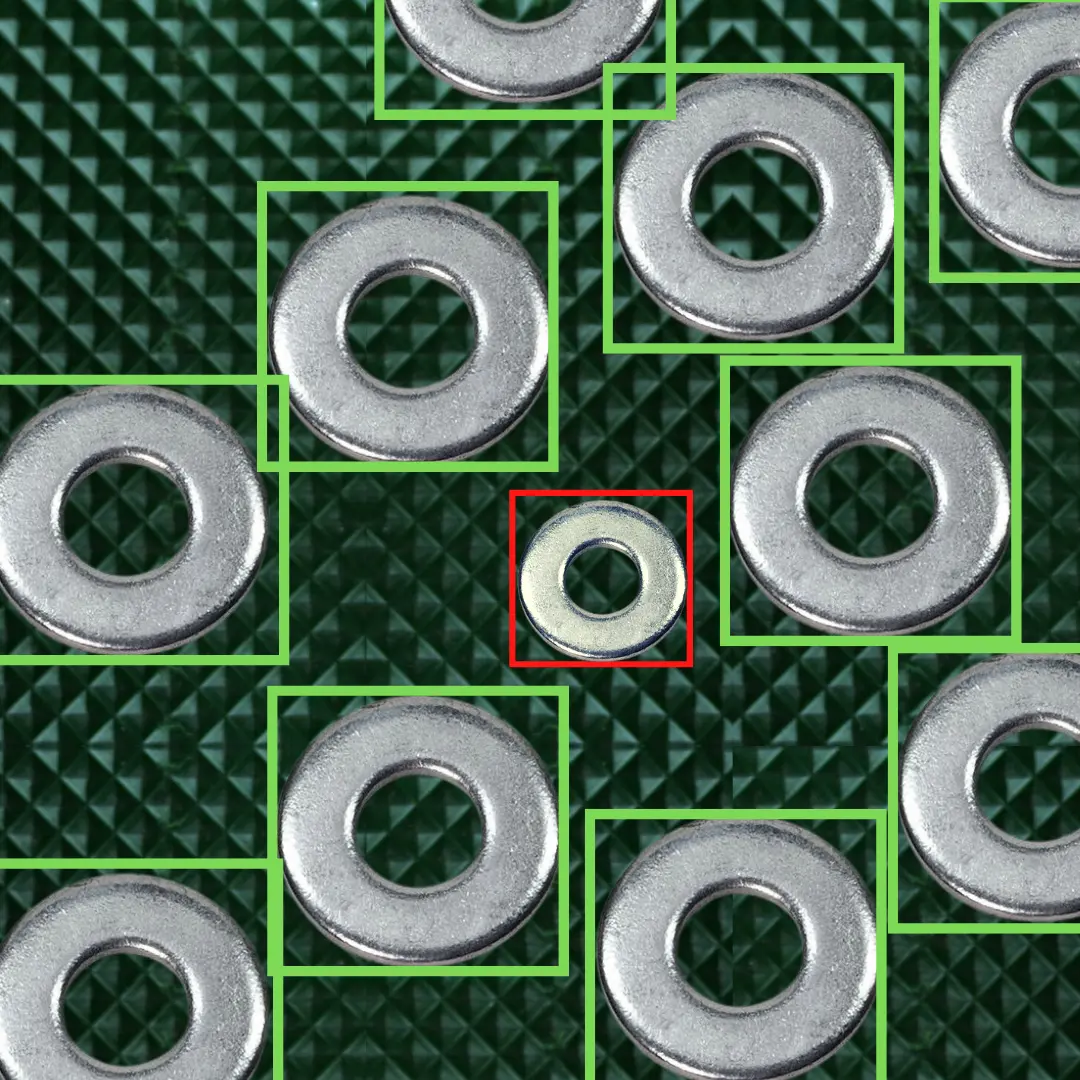

Incorrect Count

Incorrect Count

Metals like iron, steel and others differ in their density which makes them an ill-fit for weight based counting, manual counting on the other hand is not accurate and fast. Kiara Counting Systems use AI vision and Machine Learning technology to count up to 1000 parts/min with up to 100% accuracy.

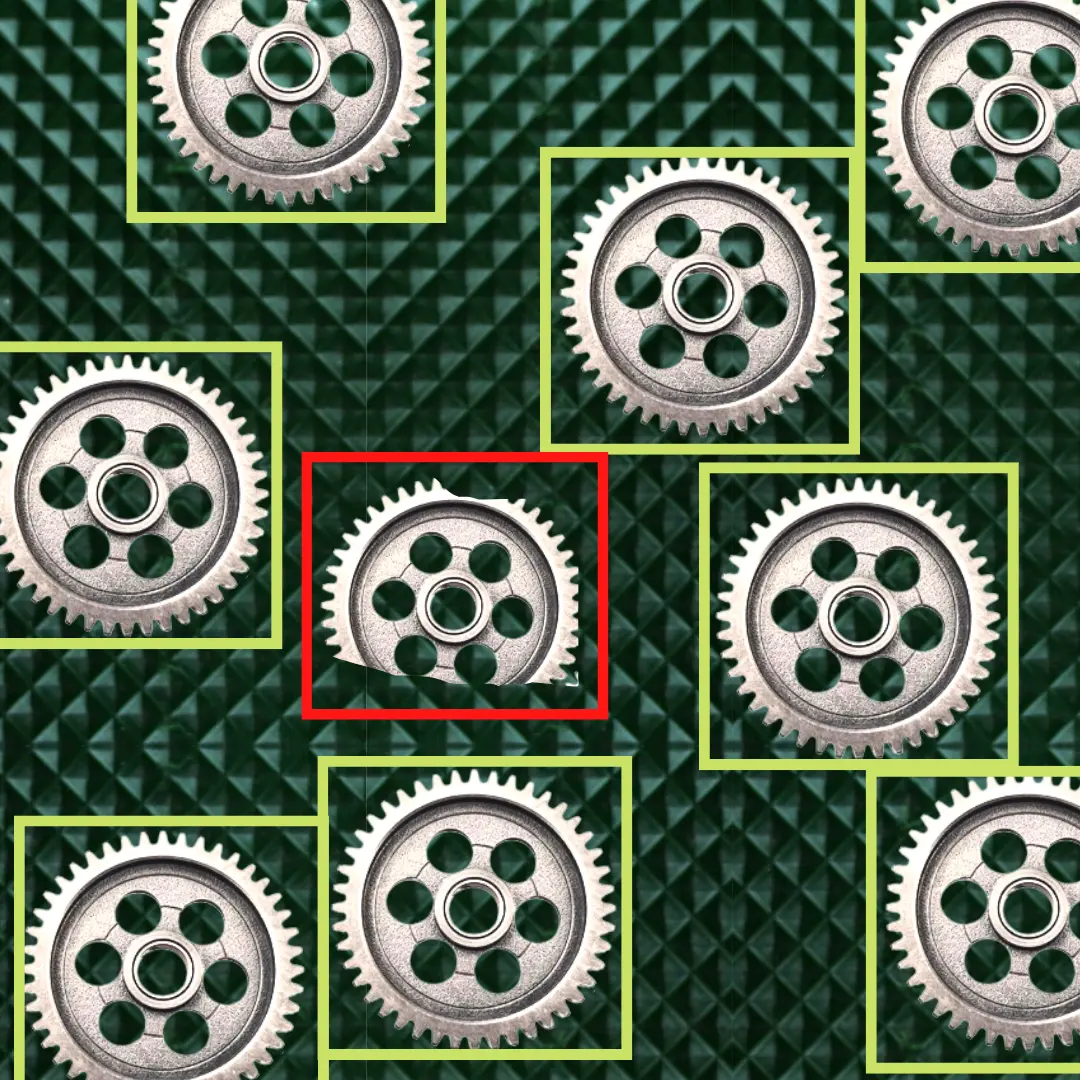

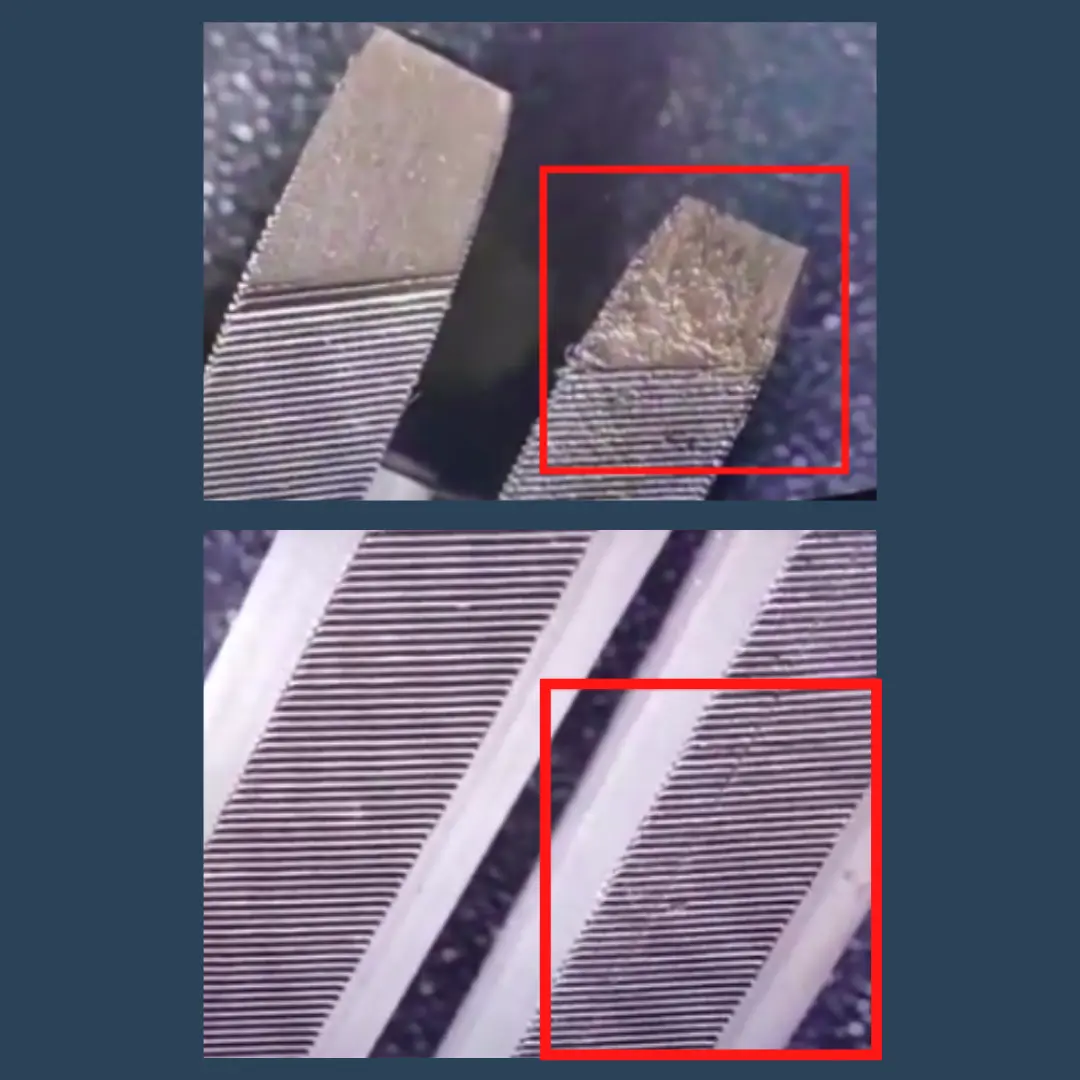

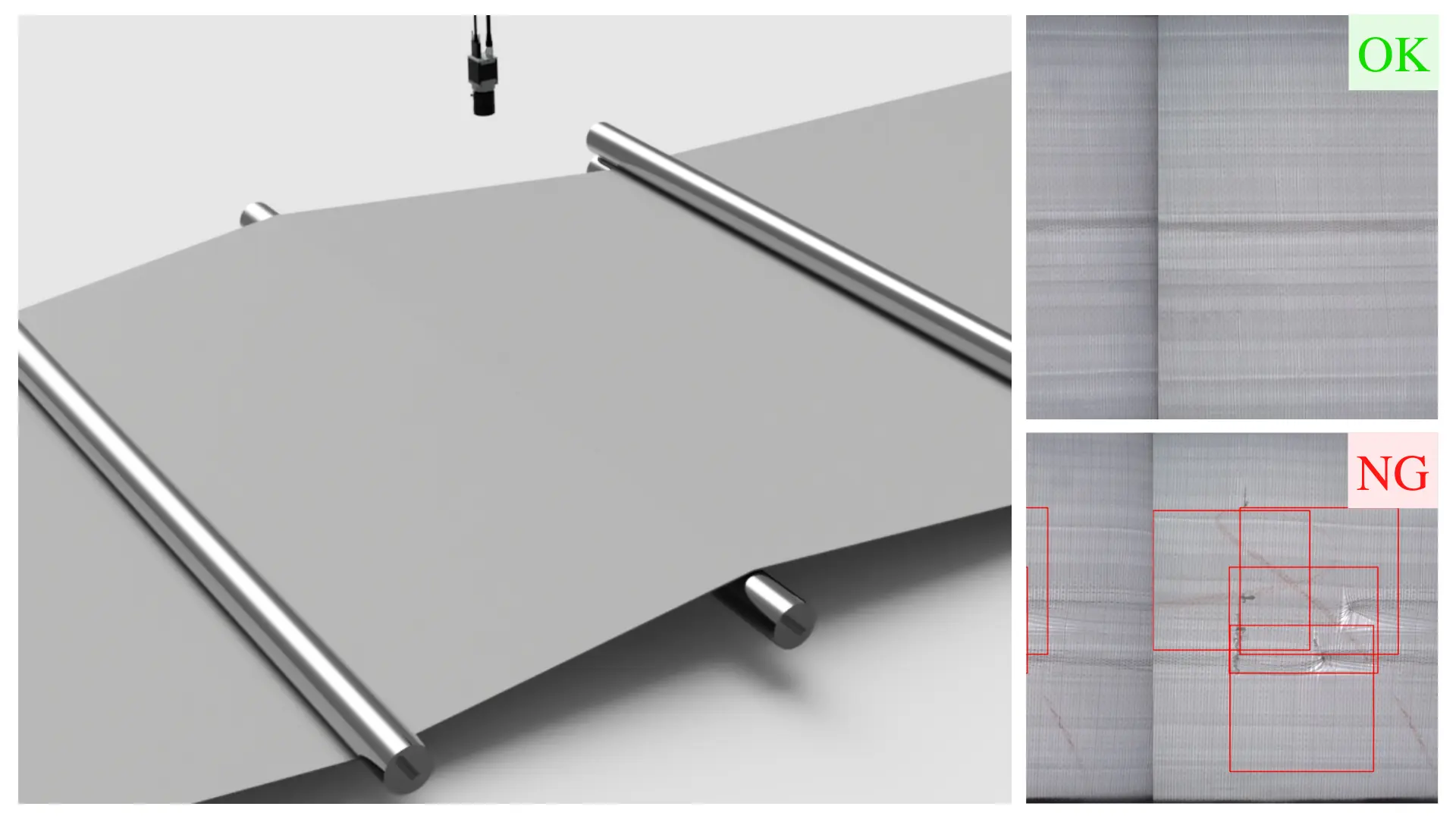

Broken/Scratched Parts

Broken/Scratched Parts

Small metal parts are prone to small scratches, chippings, and breaking during the production process, which may not be effectively visible to human eye. KVP keeps a keen eye on each product before letting them go towards shioment.

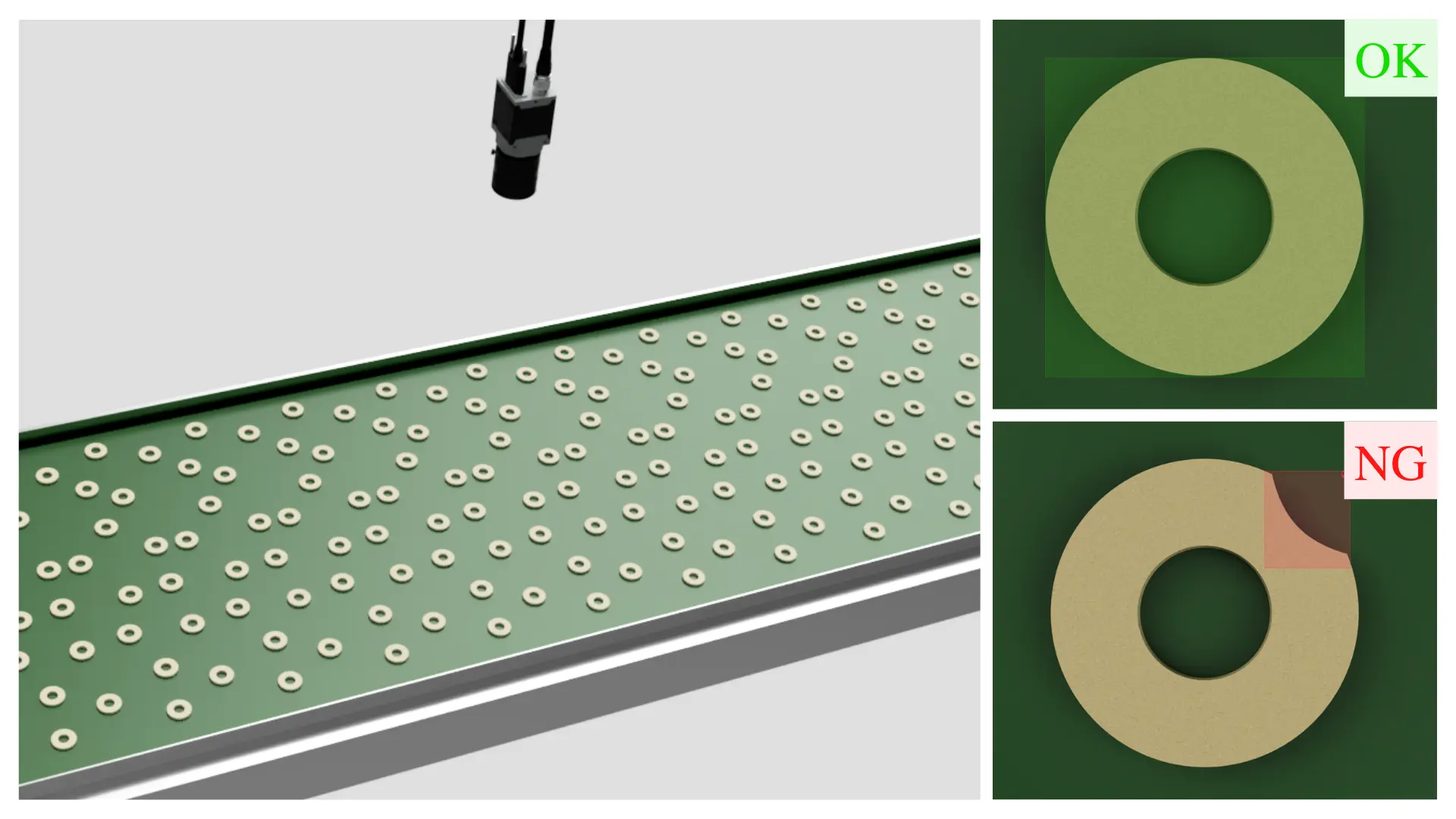

Minor Defects

Minor Defects

Small details in the manufacturing of the metal & automotive parts value a lot for any company's goodwill. Kiara Vision Platform takes into note every small defect at high speed of up to 1000 parts/min with up to 100% accuracy.

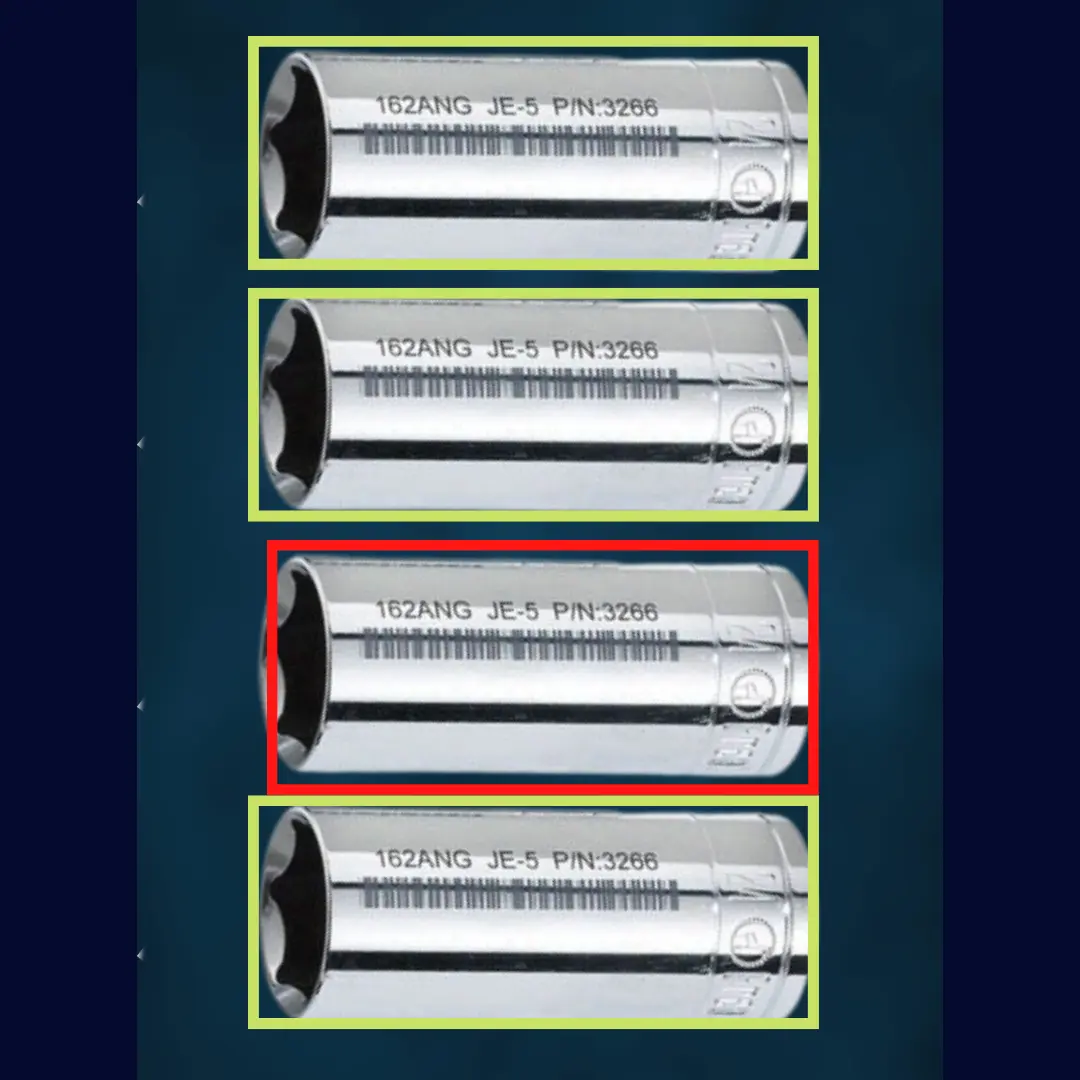

Improper Bar-code Print

Improper Bar-code Print

Bar-code is a very important factor of information on any product's packaging. It reveals a lot of necessary information about the product. Absence/Presence of barcodes and batch codes can be easily automated by AI Vision Platform – Kiara

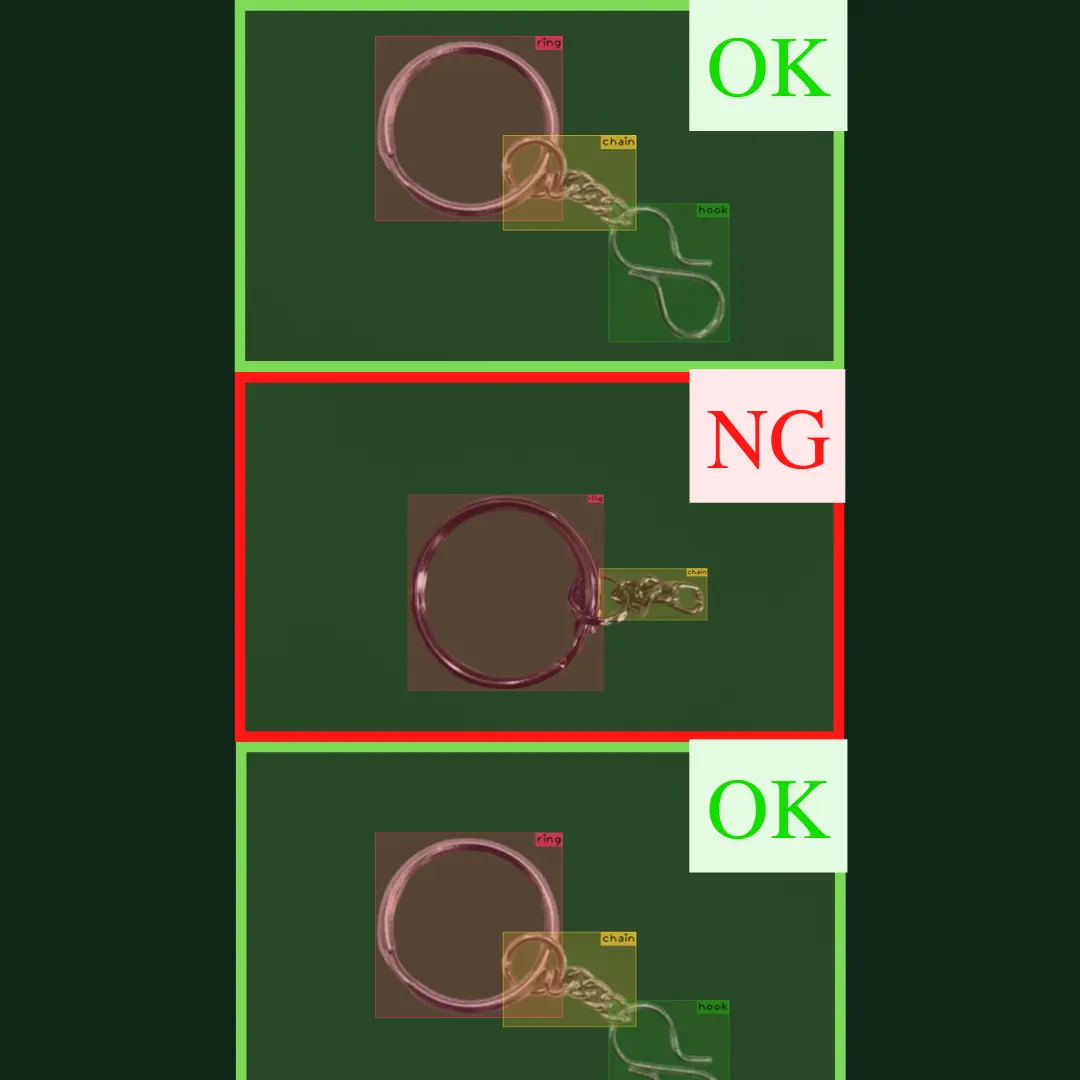

Absence/Presence

Absence/Presence

Automotive and metal products consists of several parts at times. It's necessary to make sure each part is present at the time of inspection to ensure utmost customer satisfaction. Kiara Vision Platform uses AI and Machine learning to identify each different part and ensure up to 100% accuracy at high speeds.

Kiara: AI-Enabled Vision-Based Solution for Metal & Automotive Industry 4.0

Watch In Action

Catch every Automotive & Metal defects with Kiara Vision Platform

Our Clients