Accurate and Efficient Web Inspection Systems with AI Technology

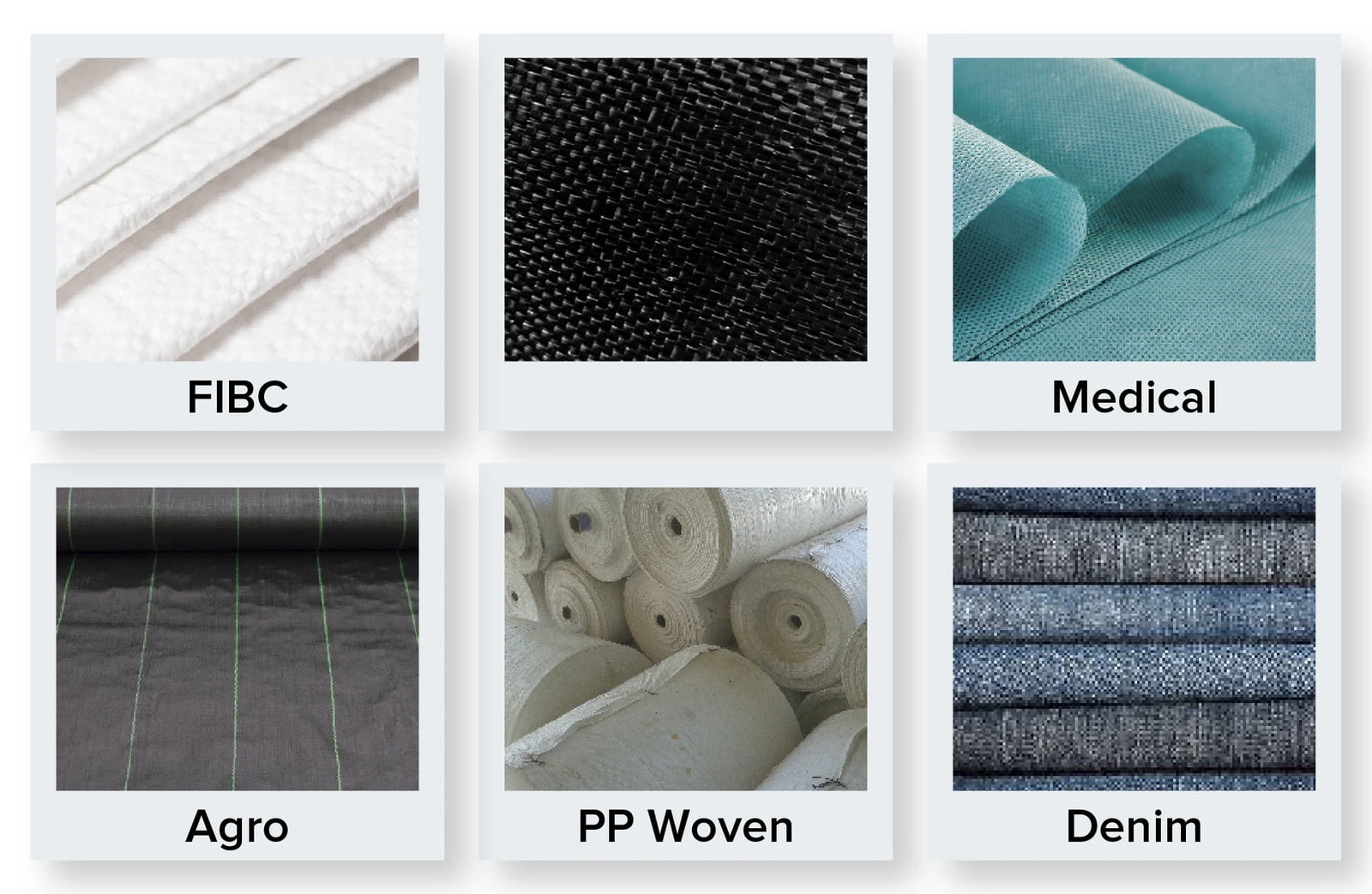

Kiara high-performance web inspection system can detect a wide range of defects at high speedin real time. It generates a comprehensive defect map that helps system operators optimize the production process, and ensures uncompromising quality control.

Our system is designed for seamless integration into any production line. Used by many major corporations and production plants across India for inspecting Textiles, Labels, Sheets, and more; our system has proven to reduce waste by 70% and ensure 100% quality control.

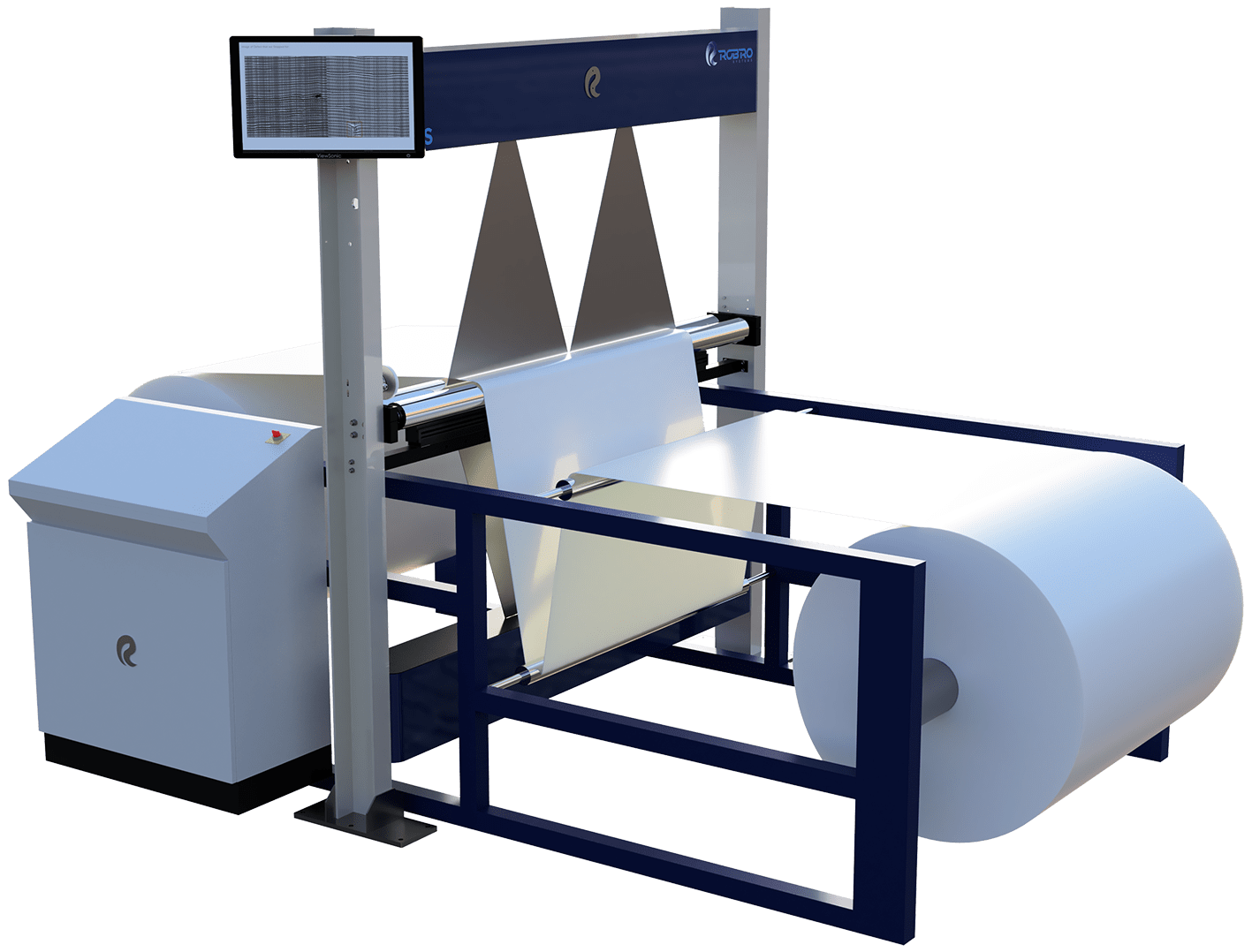

Introducing the Kiara Web Inspection System

Defected products can damage your brand reputation and business. Companies rely on rigorous quality checks, but manual inspections are time-consuming and prone to errors.

- The Kiara Web Inspection system ensures that your fabric quality is always perfect. This AI-based vision system can detect even the most minute defects and send alerts in real-time.

- The system integrates as a part of your production line. As such, it helps automate the production process by optimally removing defective parts using AI assistance.

- Kiara web inspection system is very easy to operate and requires minimal training.

- The Kiara system can become one of your trusted employee and save millions in waste material, costly recalls, and hours of manual inspection.

One simple call can increase your profits.

Get the advice you need from the experts.

How does Kiara Web Inspection System Works?

Kiara Web Inspection system simplifies the complex process of defect detection and minimizing wastage of material.

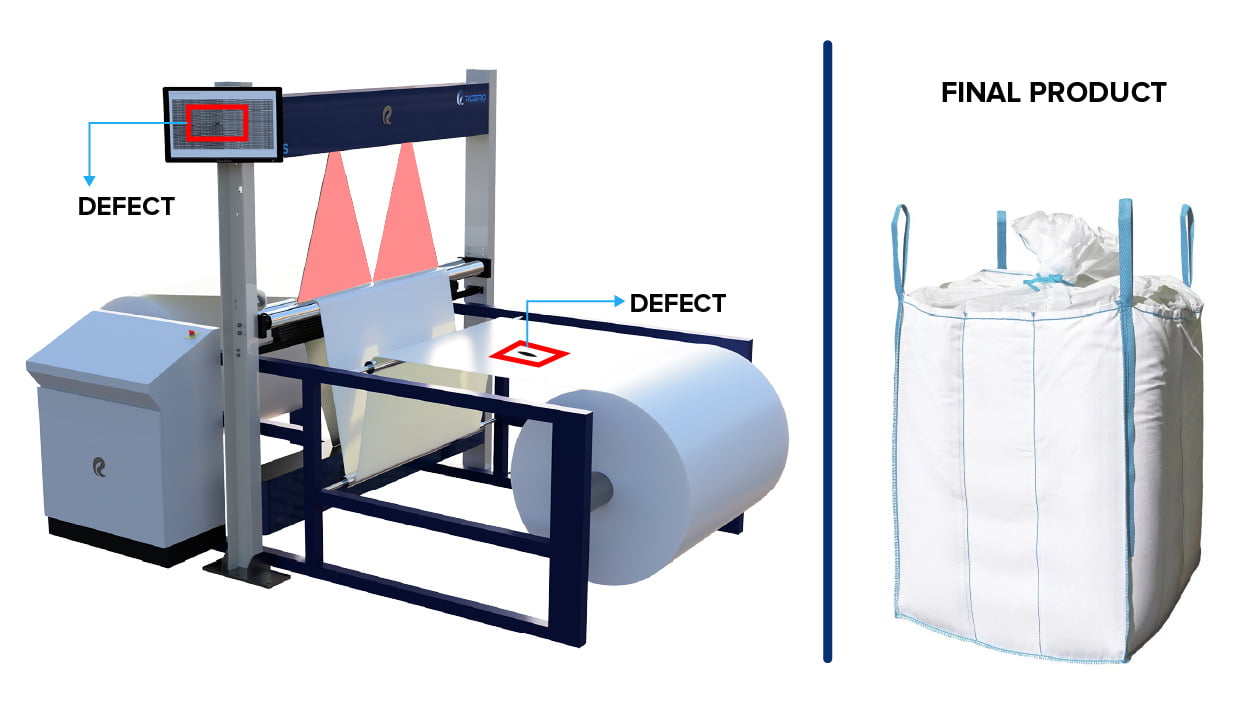

Defect Detection

Defect Detection

The Kiara Web Inspection system constantly monitors the source object like textile, sheet, label, etc. It looks for major and minor defects with 100% accuracy.

Self Learning

Self Learning

The Web Inspection System (KWIS) constantly learns and improves itself based on the defect types and detections. Thanks to self learning, the system does not need intervention and calibration as it adapts to the defect type and detection.

Reporting and Action

Upon defect detection, Kiara autonomously triggers alerts, halts operations if necessary, or executes pre-programmed actions Further more, it provides a detailed report of the defect in form of defect map and markings.

Analytics

Analytics

The Kiara Web Inspection System provides a detailed analytics about the inspection process. It helps business owners analyze the efficiency of production process, machine, and system operator.

KWIS - Product Suite

Flexible Intermediate Bulk Container Inspection

Retrofits on existing cutting machines, that’ll capture all the defects and provide optimum cut point. Consists of pre trained AI model that helps to categorize defects which is useful in creating custom recipes as per customer specification. KWIS conducts high-speed inspections, scanning at the rate of 120 meters per minute

KWIS - Roll Inspection System

KWIS - Roll to Roll uses a hybrid approach of traditional and AI technologies to perform high-speed inspection on roll winding and rewinding machines, with all data captured digitally. For each variant, a master pattern is created and used by intelligent pattern matching to identify deviations. AI then classifies defect categories, becoming smarter as more data is fed

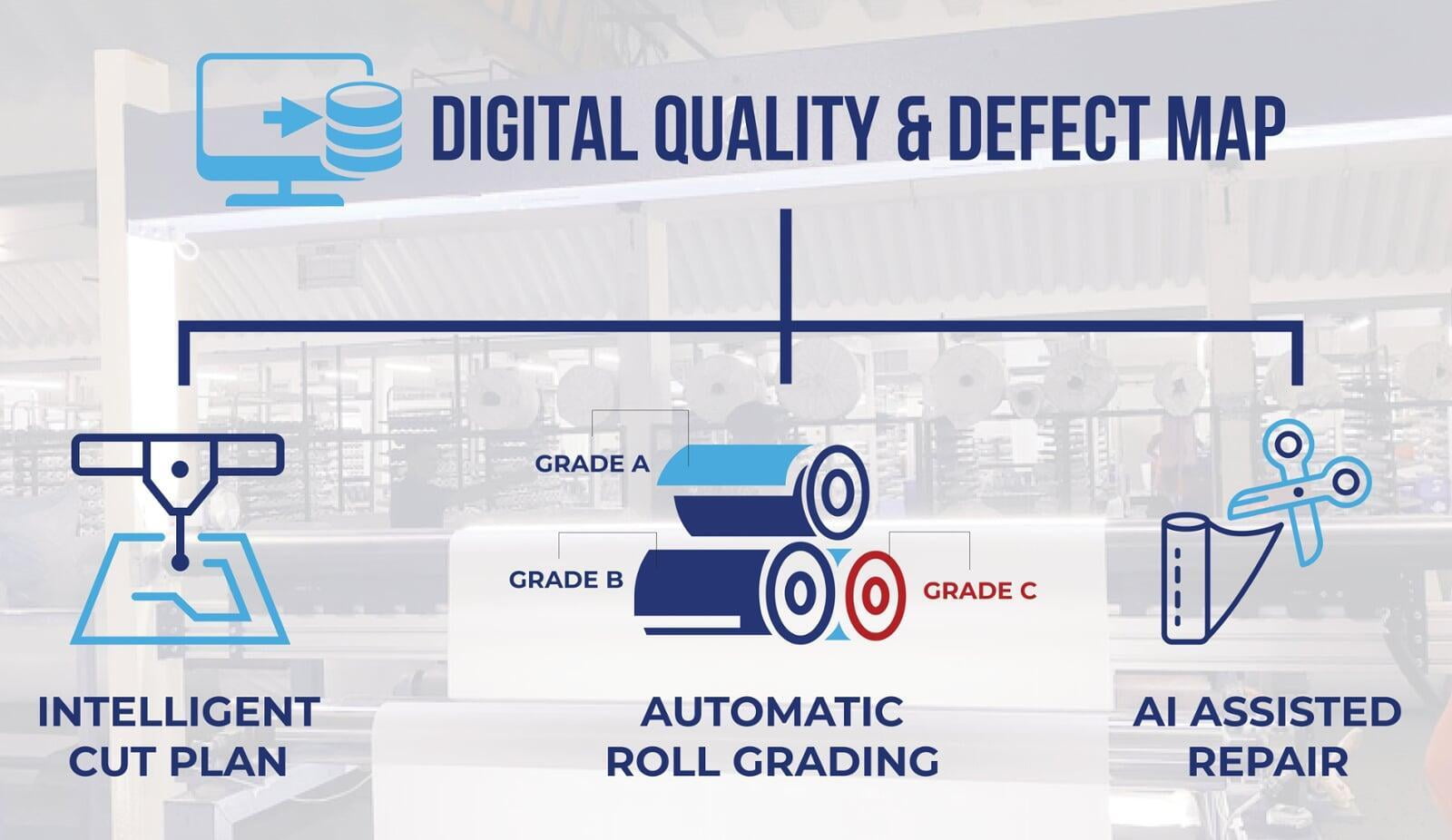

KWIS - Roll Master Review Software

KWIS - Roll Master software provides digital access to all data captured from KWIS , including defect images and locations. This enables roll grading and evaluation, with features such as a digital defect map, filters to select defect types, roll-wise defect categorization, and data preparation to stop at specified defect locations.

Kiara Web Inspection System Features

Testimonials

Our Clients