Improve your Quality with

AI Automated Inspection

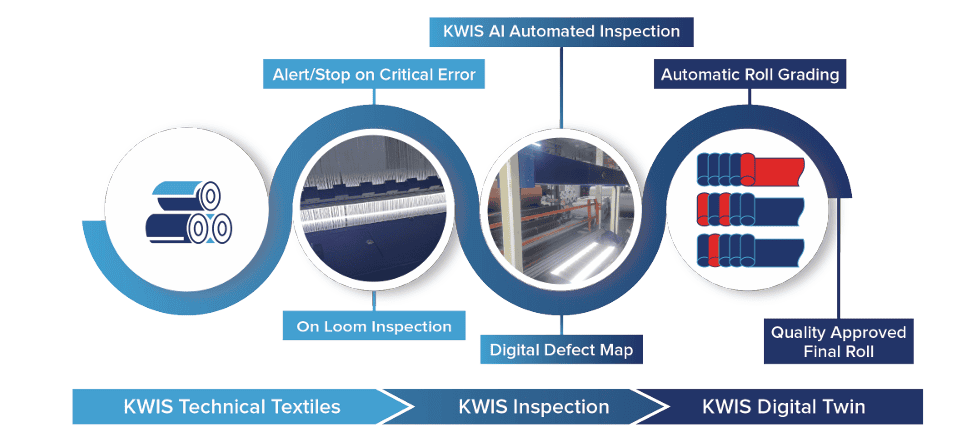

Kiara Web Inspection System (KWIS) for tire cord fabric revolutionizes quality control with AI-driven defect detection. Designed for seamless integration into tire cord weaving lines, KWIS ensures real-time monitoring, precise defect identification, and proactive quality management.

By detecting irregularities at the earliest stage, it minimizes waste, optimizes raw material usage, and enhances first-pass yield. Advanced AI models, combined with high-speed vision systems, classify defects with accuracy, addressing both visible and subtle imperfections. KWIS empowers manufacturers with data-driven insights, reducing manual inspection efforts and ensuring consistent high-quality tire cord production.

About Kiara Web Inspection system for Tire Cord Fabric

About Kiara Web Inspection system for Tire Cord Fabric

What It Does

KWIS ensures seamless quality control for tire cord fabric by detecting defects at critical production stages:

2. At the Dipping Line:

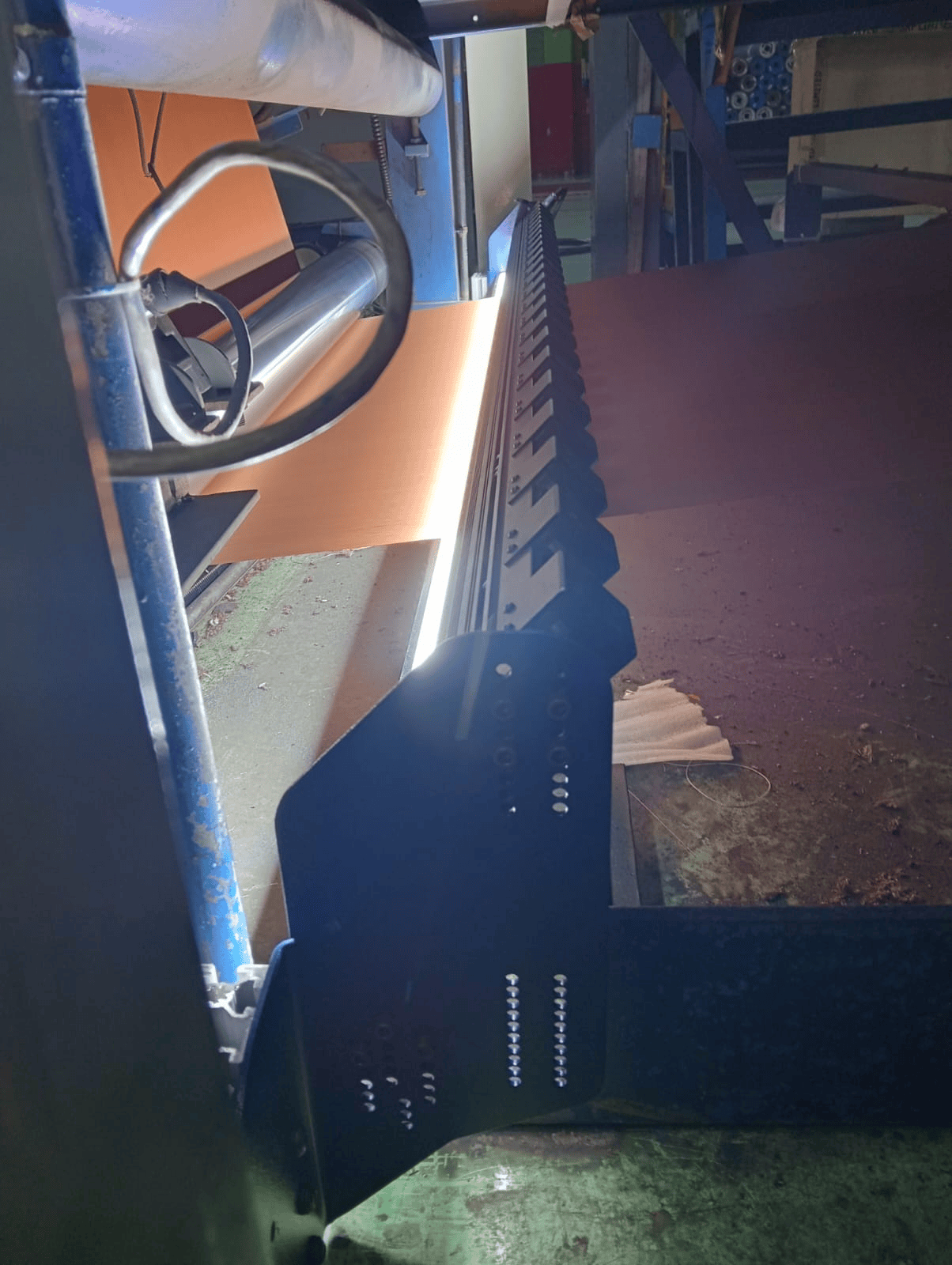

1. On Loom Inspection:

- Continuously monitors the weaving process.

- Instantly detects defects and triggers a buzzer alert.

- Enables operators to take immediate corrective action.

- Prevents defective material from progressing further.

2. At the Dipping Line:

- Performs automated inspection post-dipping.

- Creates a comprehensive defect map.

- Classifies defects based on severity.

- Ensures precise grading and reduces second-quality production.

Defects Categories

Defects Categories

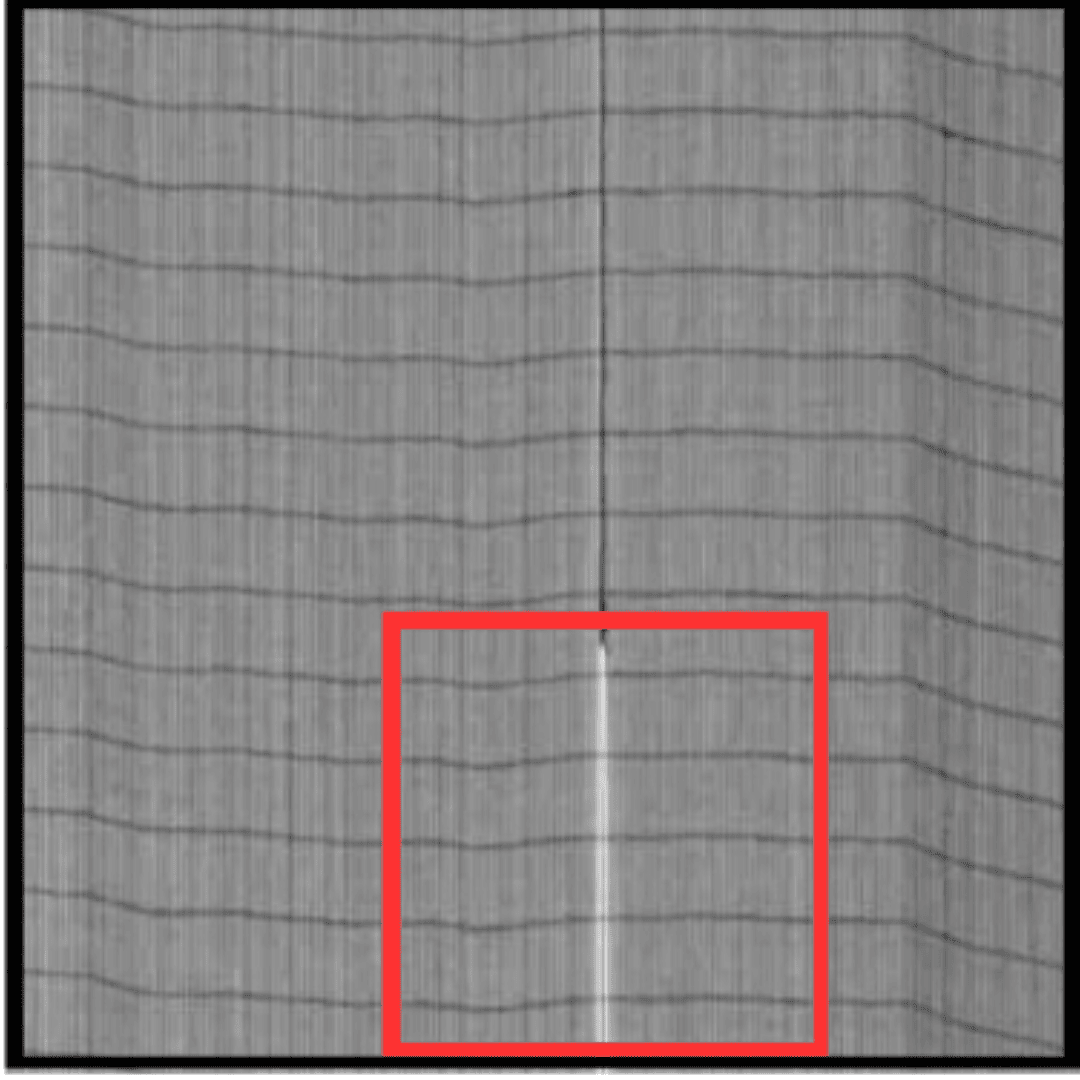

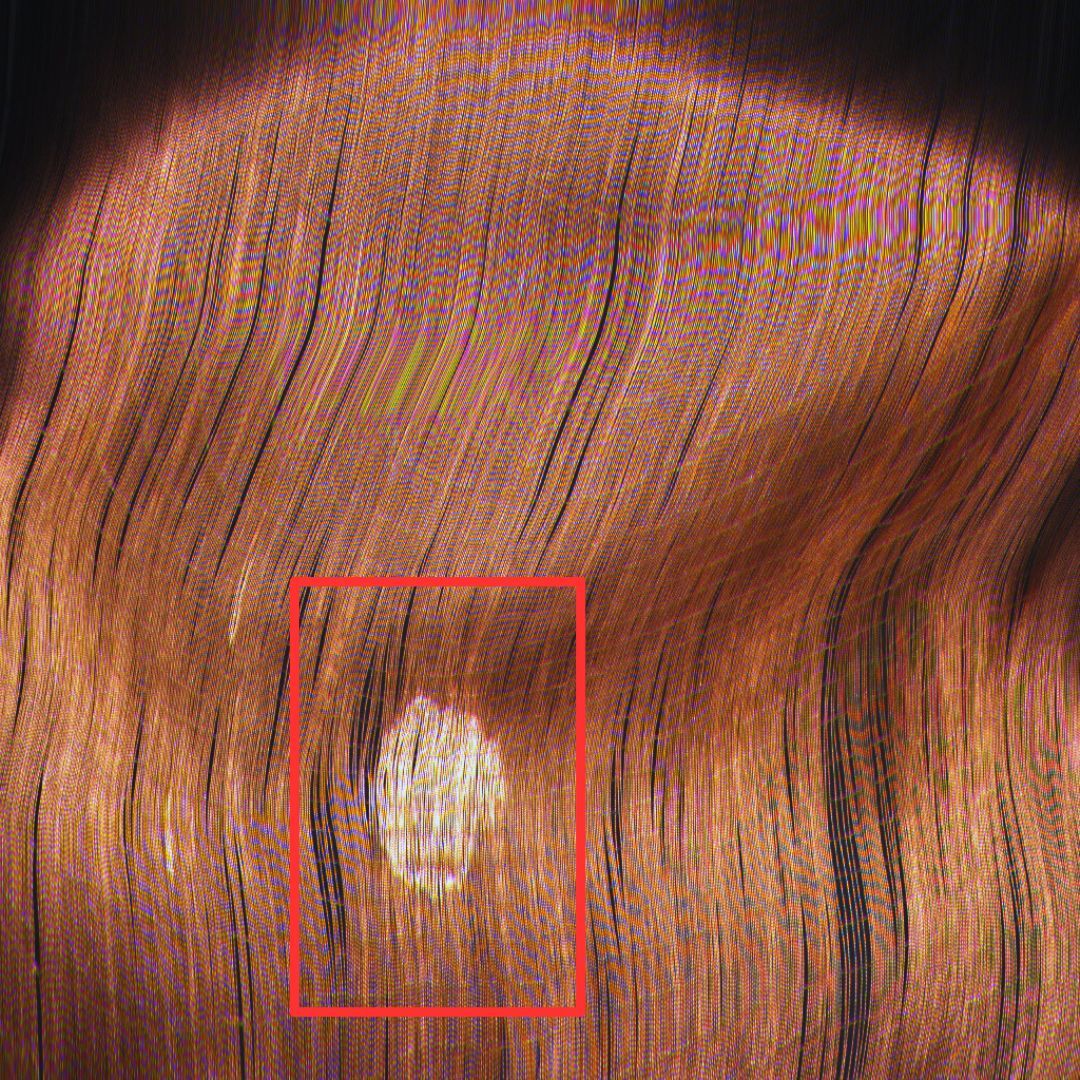

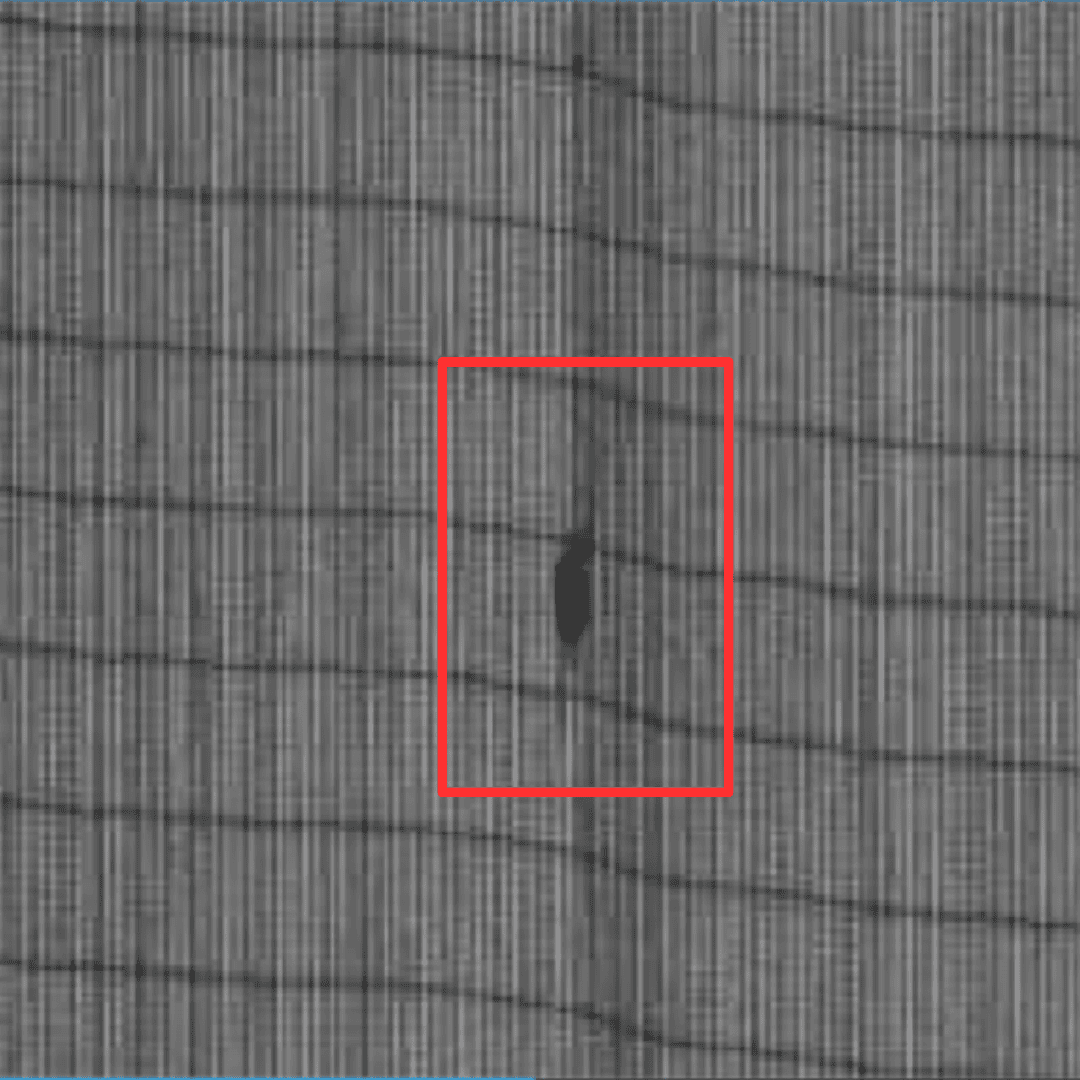

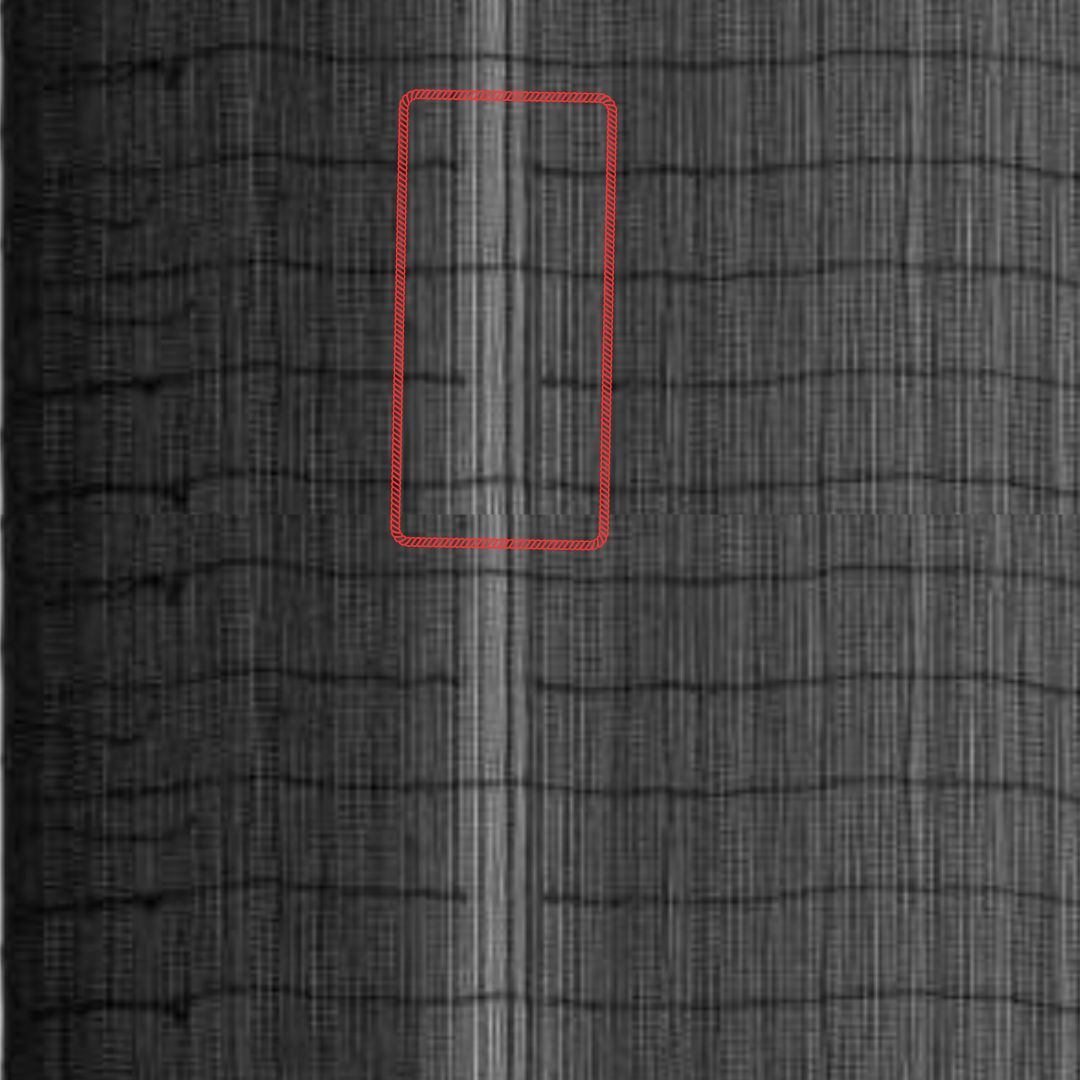

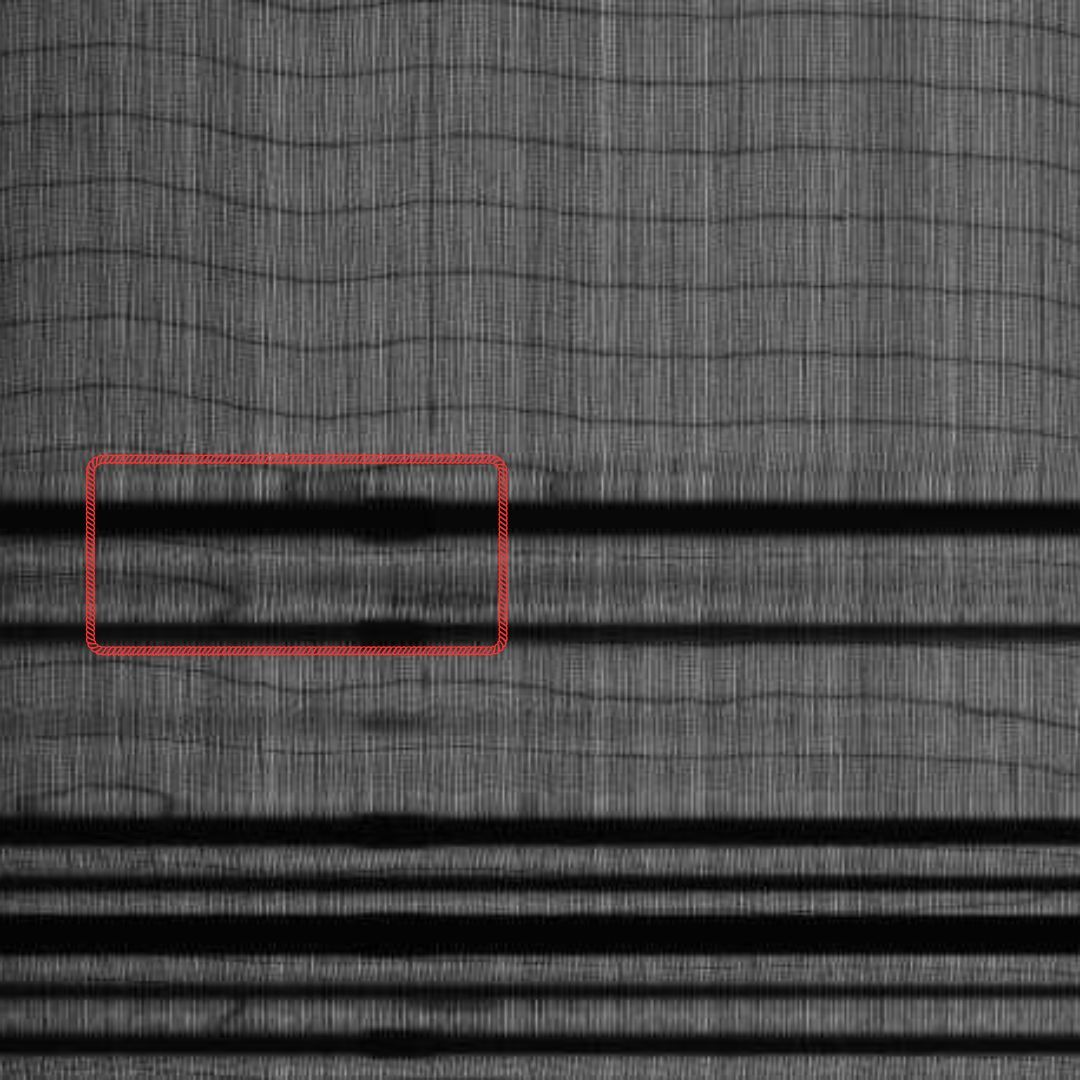

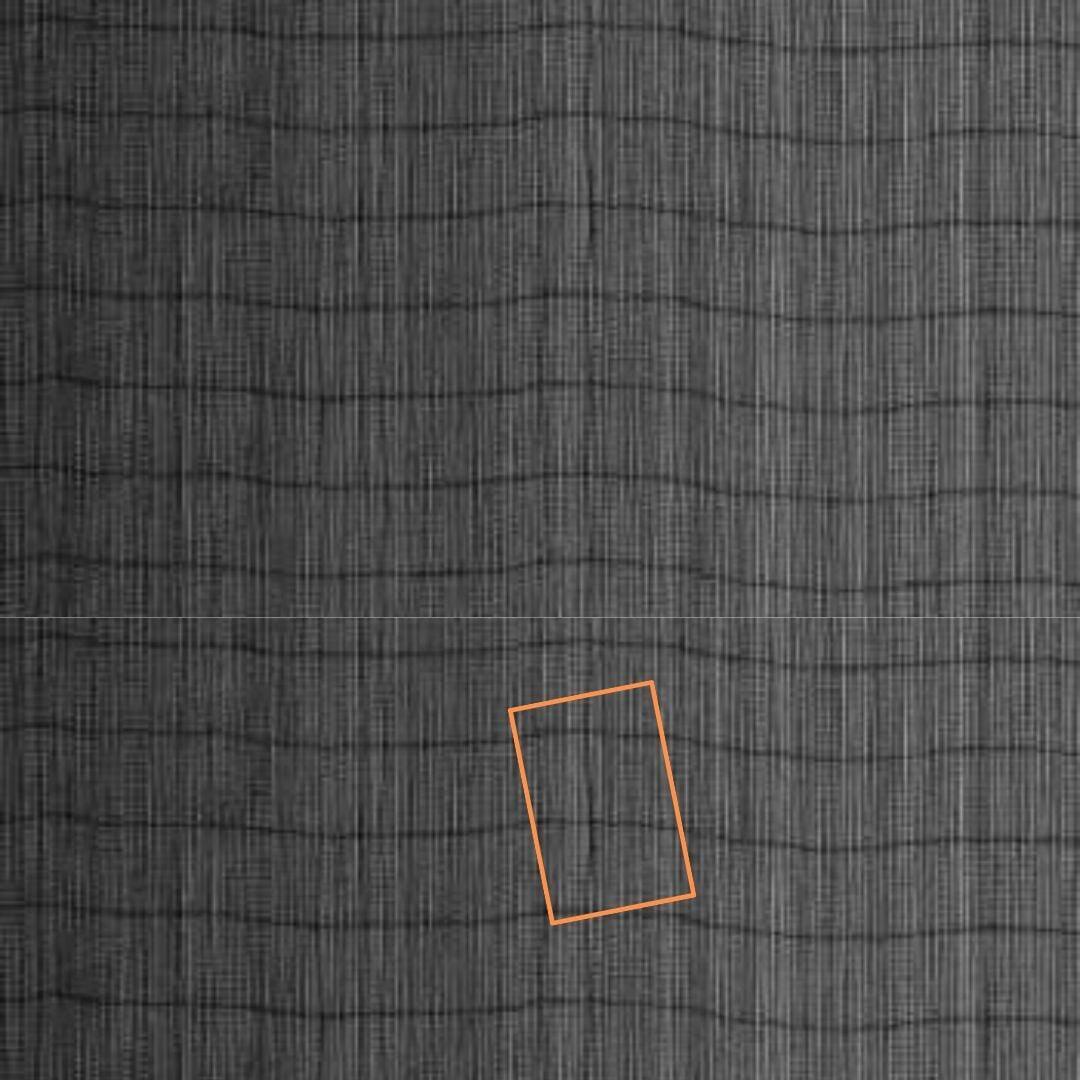

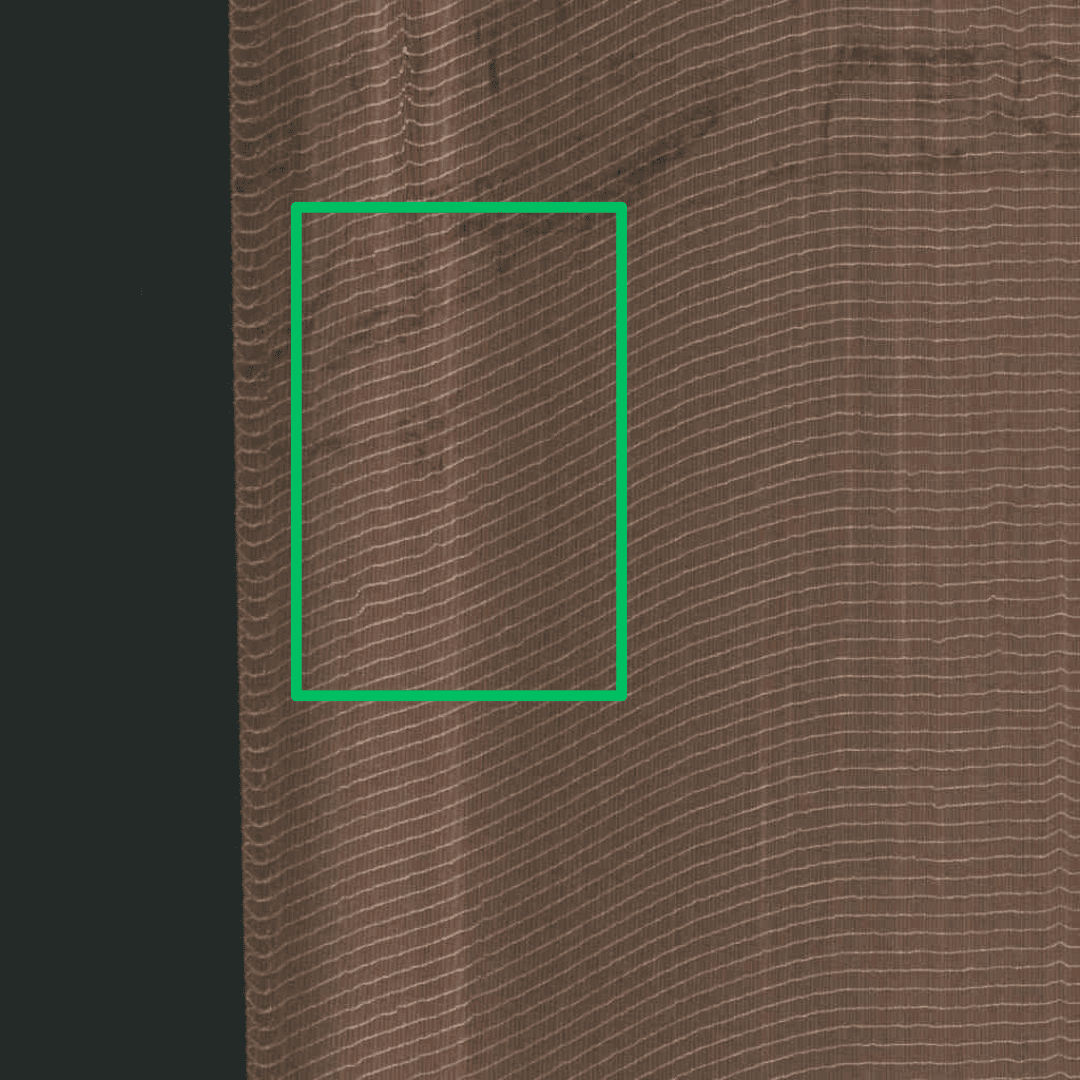

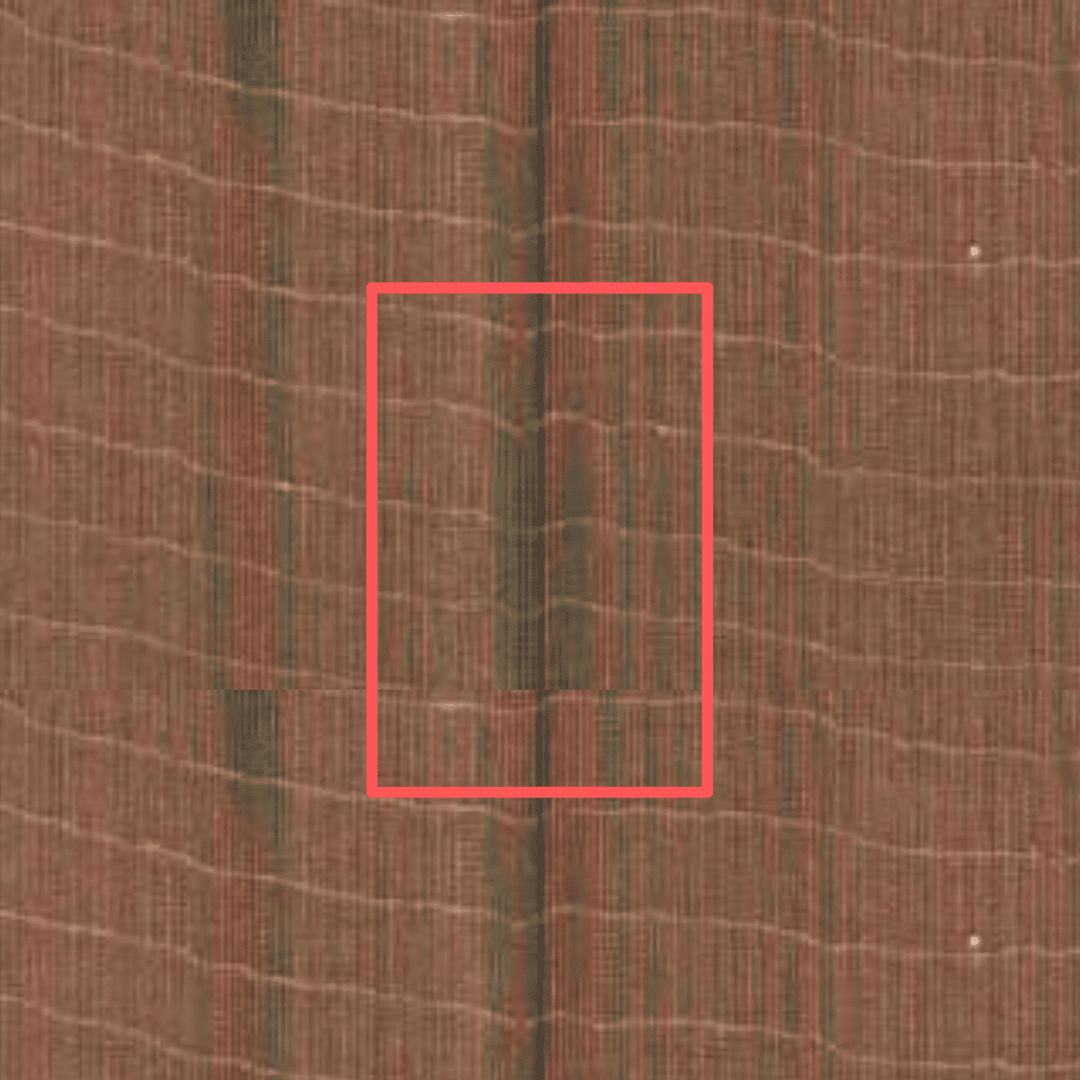

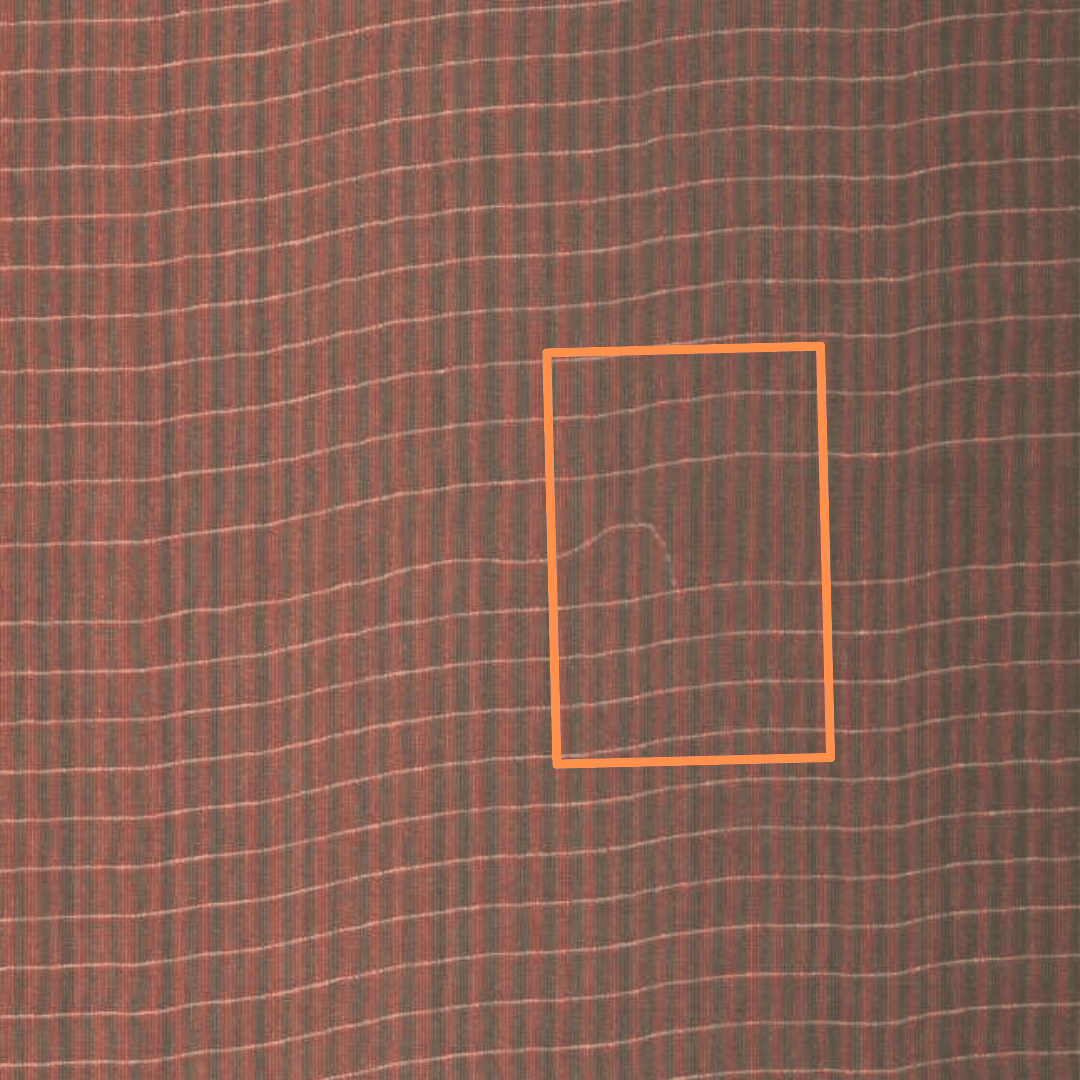

Cord Cut

Splice

White Marks

Black Particles

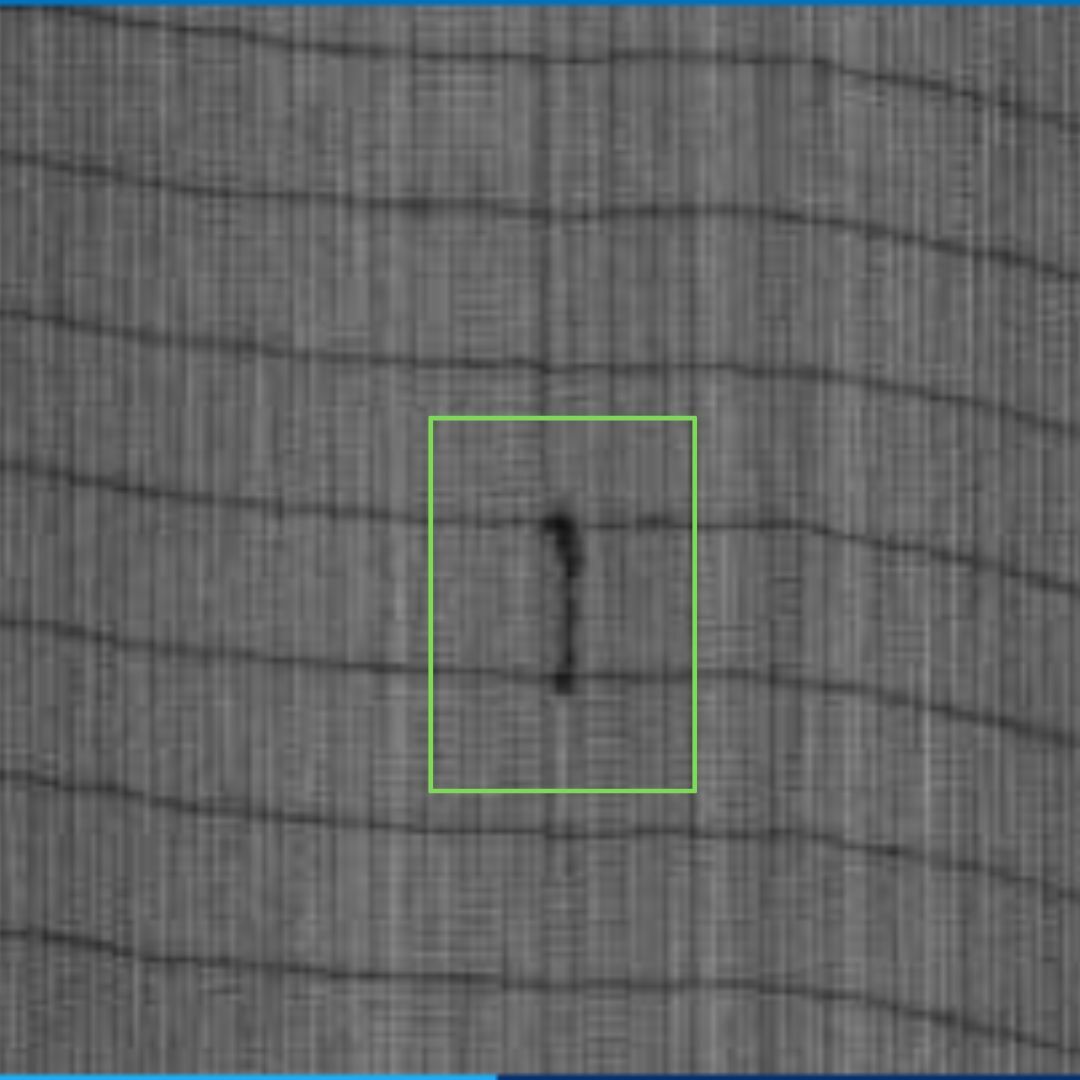

Loopy

Folding

Header

Loose Cord

RFL Marks

Defective Cord

Close Pick

Miss Pick

Features of KWIS Roll Master & KWIS Review

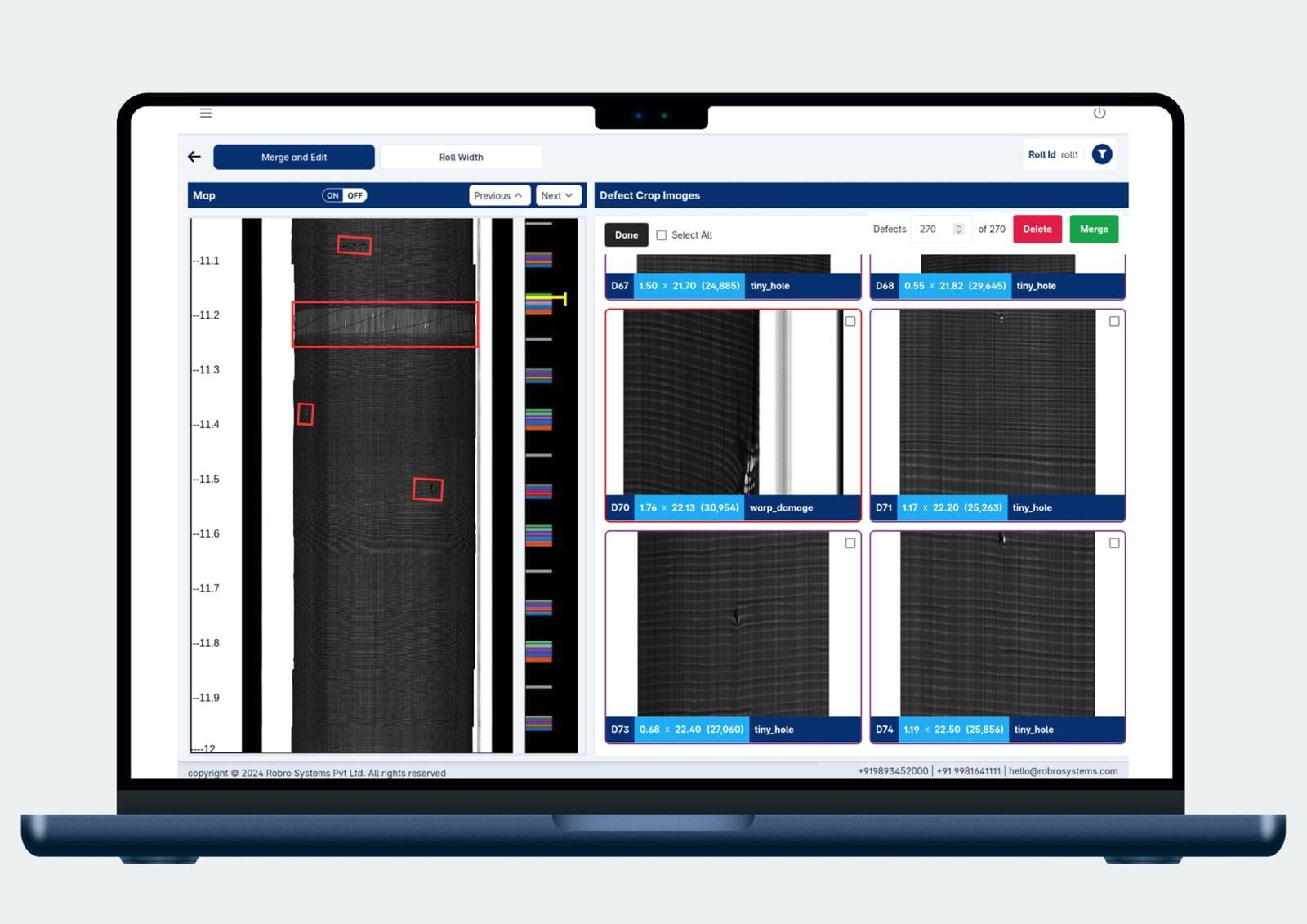

Digital Twin

Generates a Digital Defect Map of defect locations and types, enabling review of fabric inspection data and informed decision-making.

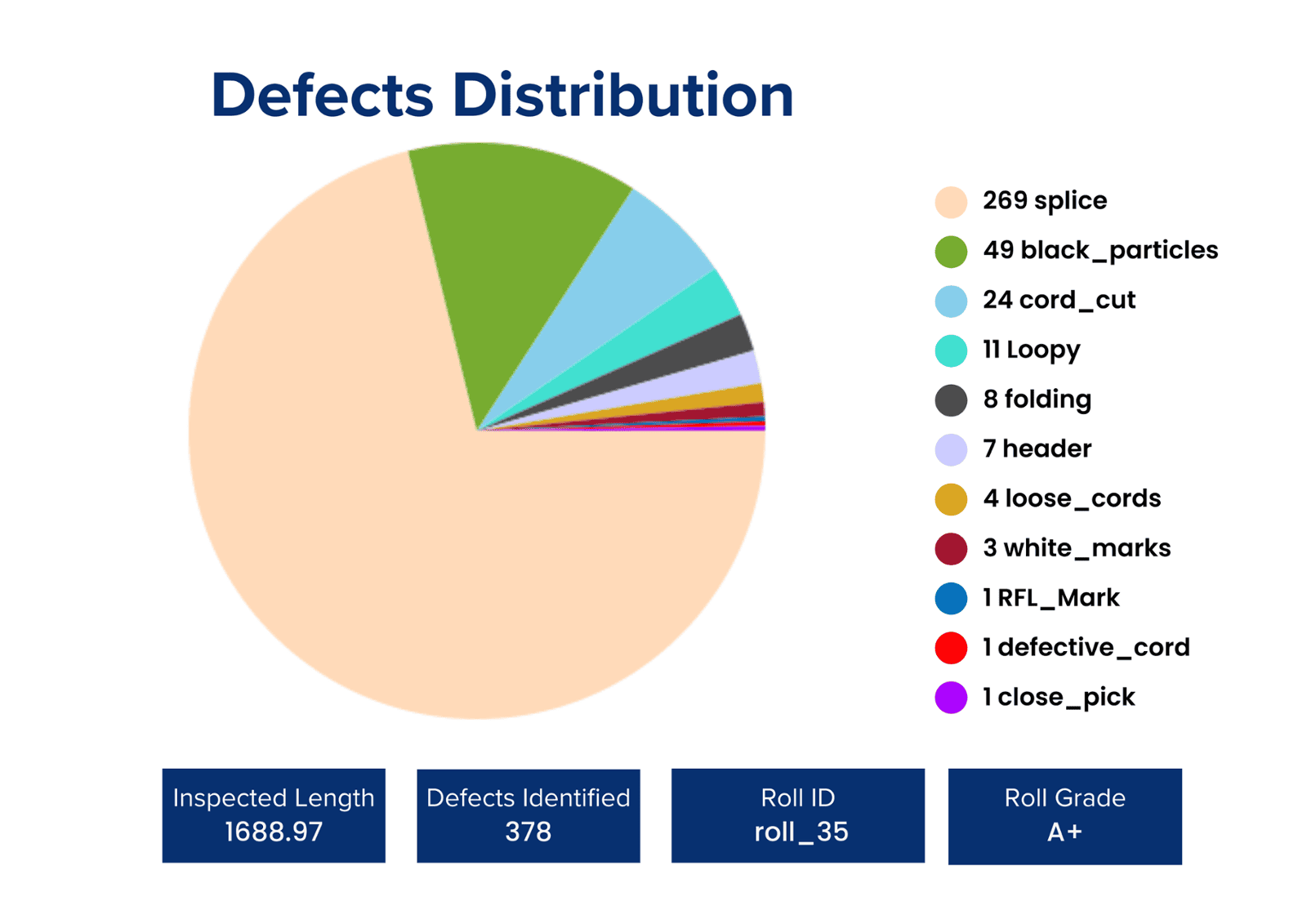

Defect Classification & Roll Grading

KWIS' AI Engine identifies all defects, as small as 2 mm, and at speeds up to 120 meters/minute.

Alert on Critical Errors

KWIS automatically sends an SMS alert to a specified mobile number when a variation exceeds the tolerance limit, triggering a fault state.

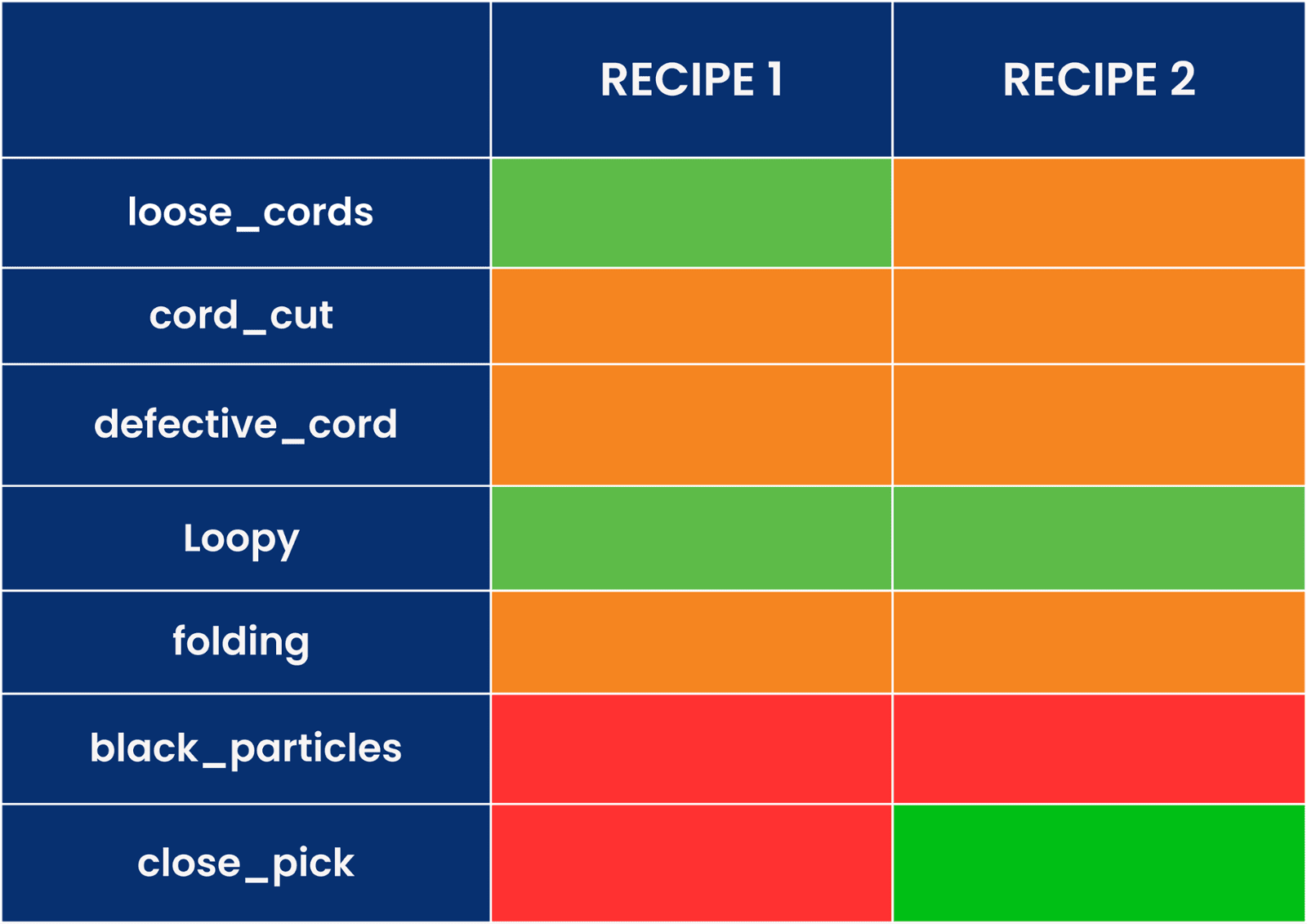

Customize Defect Detection

Diversify inspection strategies with KWIS recipe customization. Select from distinct defect categories, and precisely configure their identification criteria to meet the specific quality control requirements

Width Measurement

Automatically measures fabric width in real-time, ensuring consistency and detecting width variations during inspection.

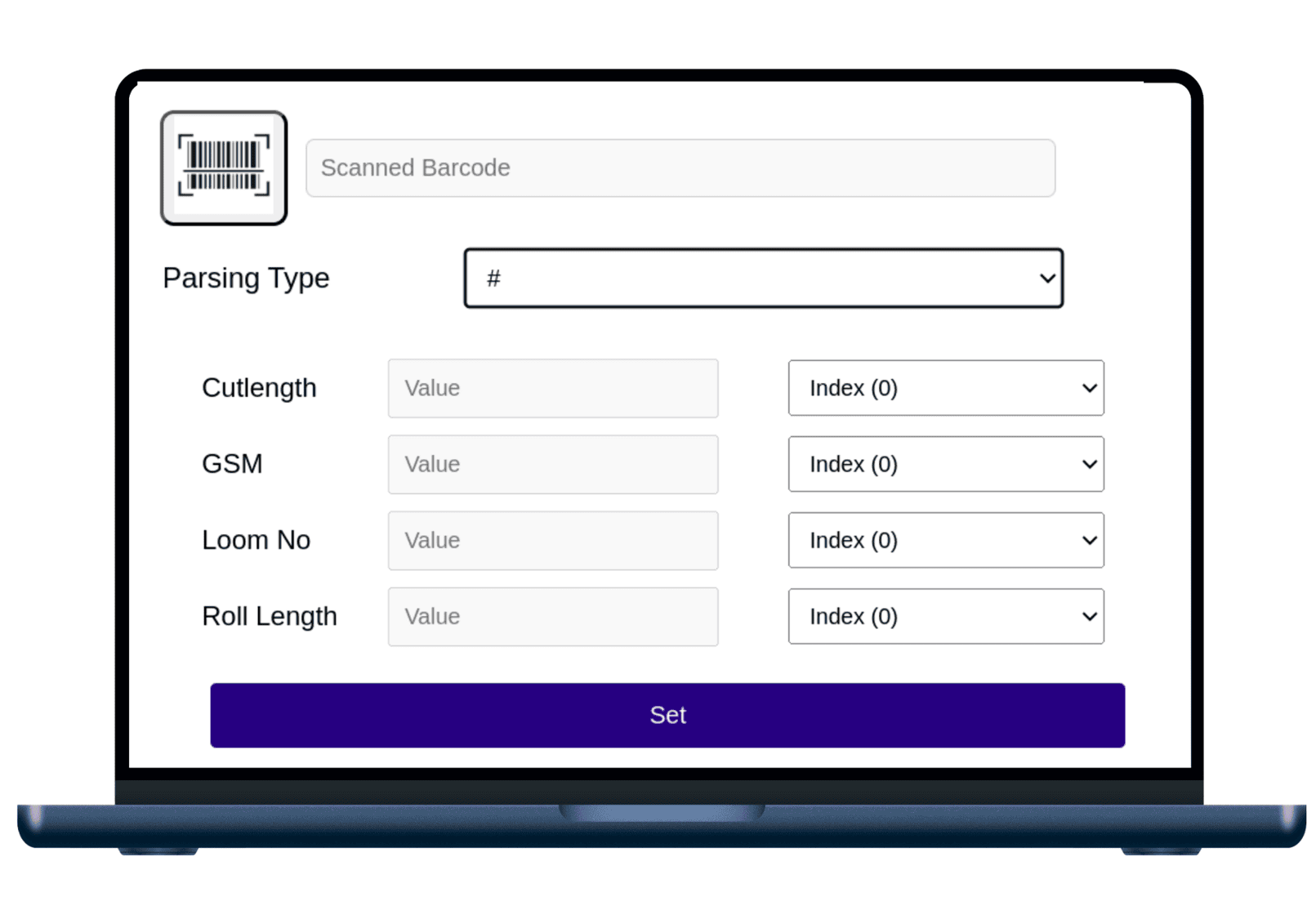

Barcode Integration

Enables automatic entry of Roll ID, Loom ID, and GSM, ensuring accurate and efficient data logging for seamless traceability.

Benefits of Kiara Web Inspection System (KWIS) for the Tire Cord Industry

- High Detection Accuracy – KWIS achieves up to 99.95% defect detection accuracy, ensuring even the smallest irregularities are identified at the earliest stage.

- Reduction in Second-Quality Production – By preventing defects in real-time, KWIS helps reduce second-quality tire cord production by up to 80%, leading to higher profitability and material savings

- Reduced Material Waste – By stopping defects at the source, KWIS minimizes raw material wastage and optimizes fabric utilization.

- Automated Inspection & Reporting – Real-time monitoring and automated defect classification streamline quality control processes, reducing dependency on manual inspections.

KWIS - Resources

Our Clients