Kiara Machine Vision - Case Studies

FIBC Defect Identification

AI Powered defect identification, auto recutting of material for minimal wastage. Read more...

PVC Parts Counting

Automatic counting of variety of plastic parts with AI technology.

Bulk Metal Parts Counting

Counted Metal Parts using AI Vision

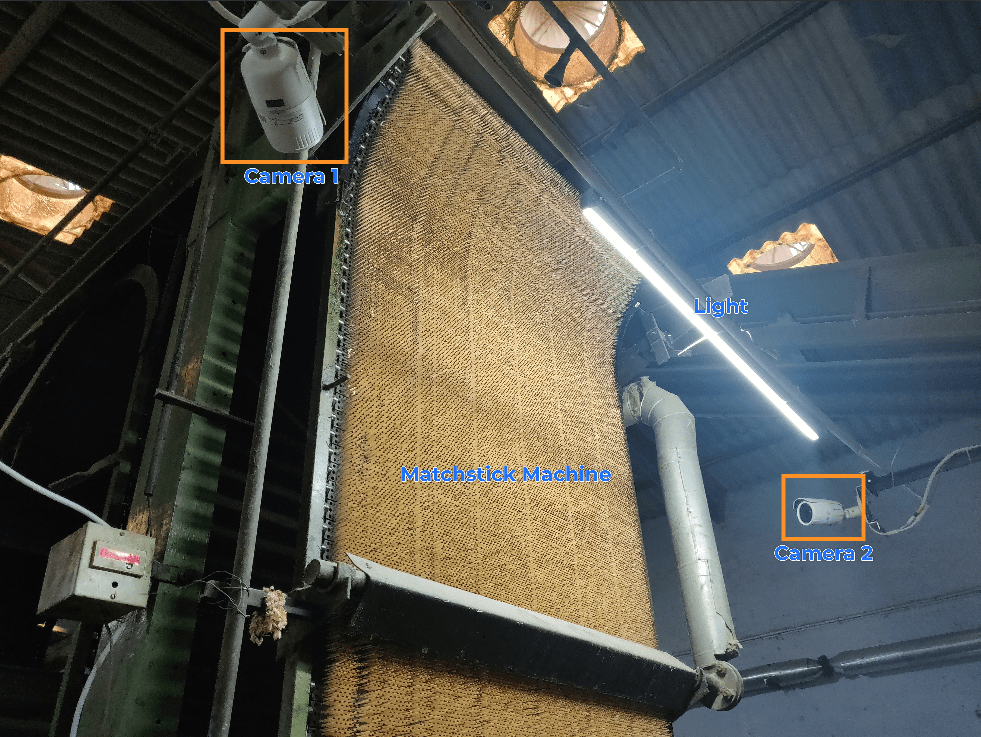

Headless Match Sticks Inspection

identifying defective matchsticks that do not have heads.

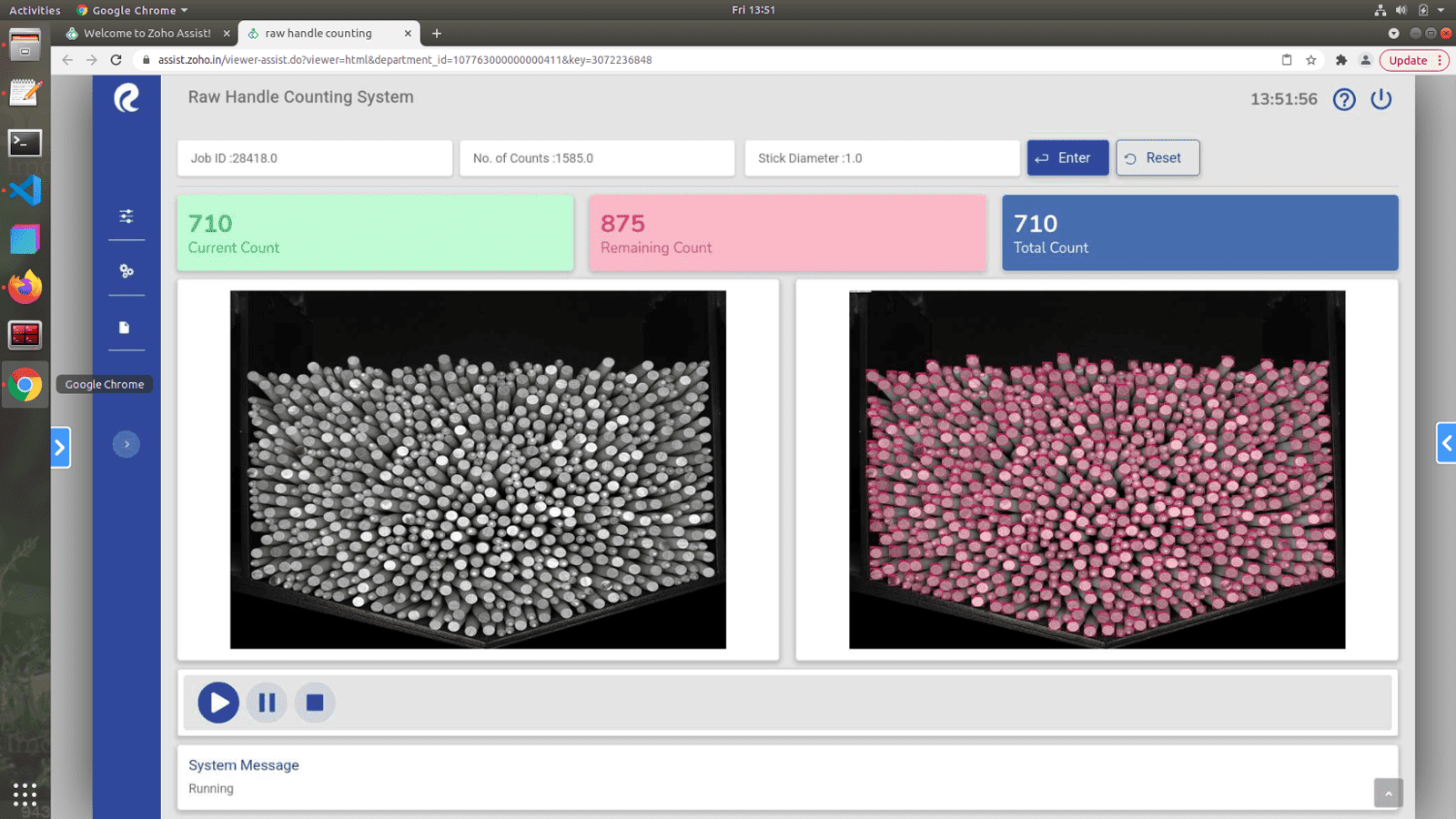

Handle Counting System

Bunch counting and packing of long elongated parts using AI technology.

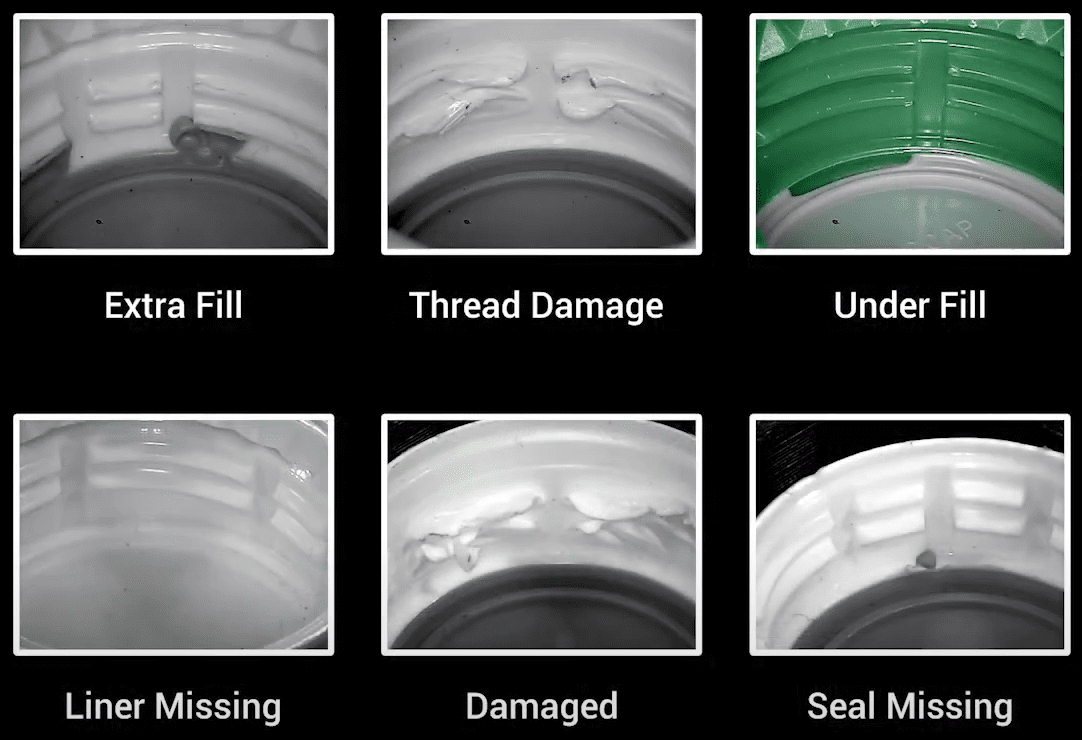

Sorting Defective Caps

Identifying defective caps and sorting the defect caps into respective category.

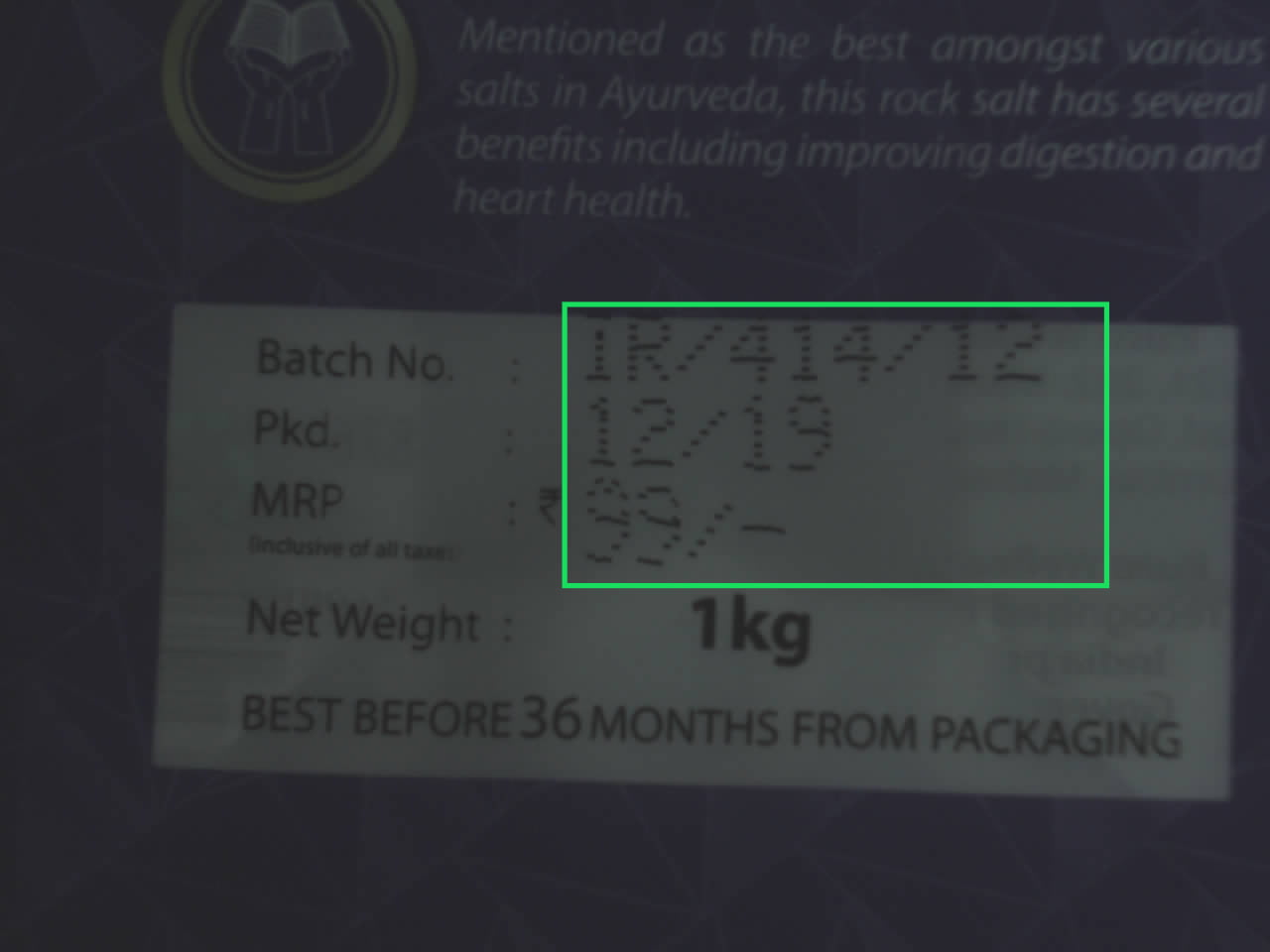

Expiry Date Print Inspection

Inspect Expiry date and batch details printed on tetrapack

Hole Choke Identification

Inspecting chokes of micropores in a spinneret.

Plastic dripper defect Identification

High speed inspection and rejection of defective drippers.

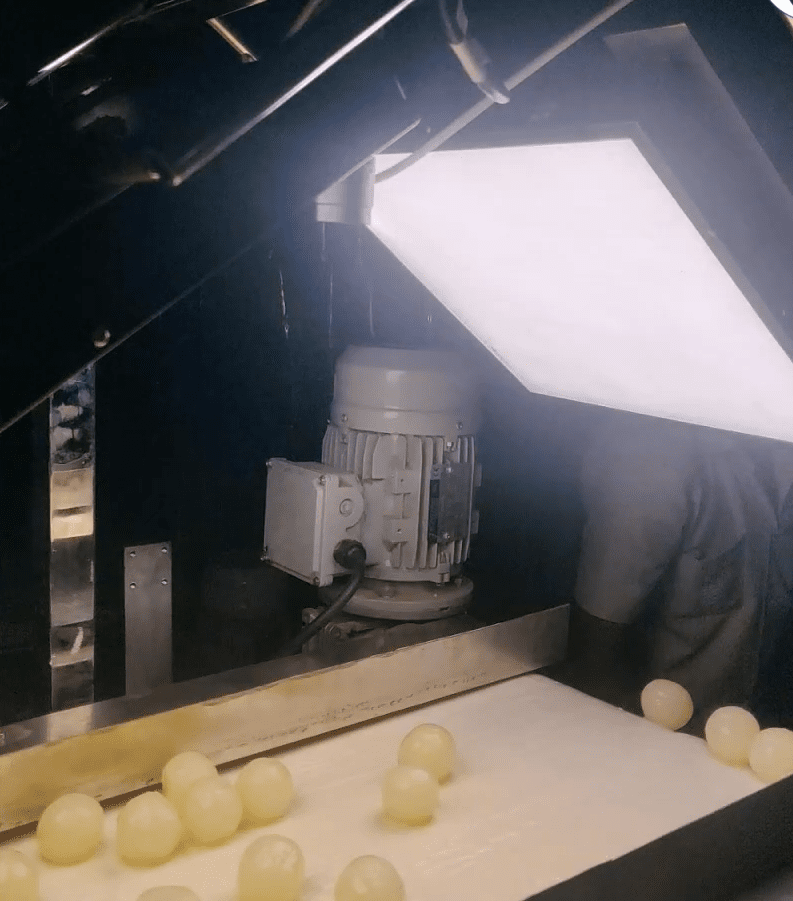

Sweets Counting on Conveyor

Counting sweets moving on a conveyor using AI technology.

High Speed Fasteners Counting

Bulk and high speed fasteners counting and packing.

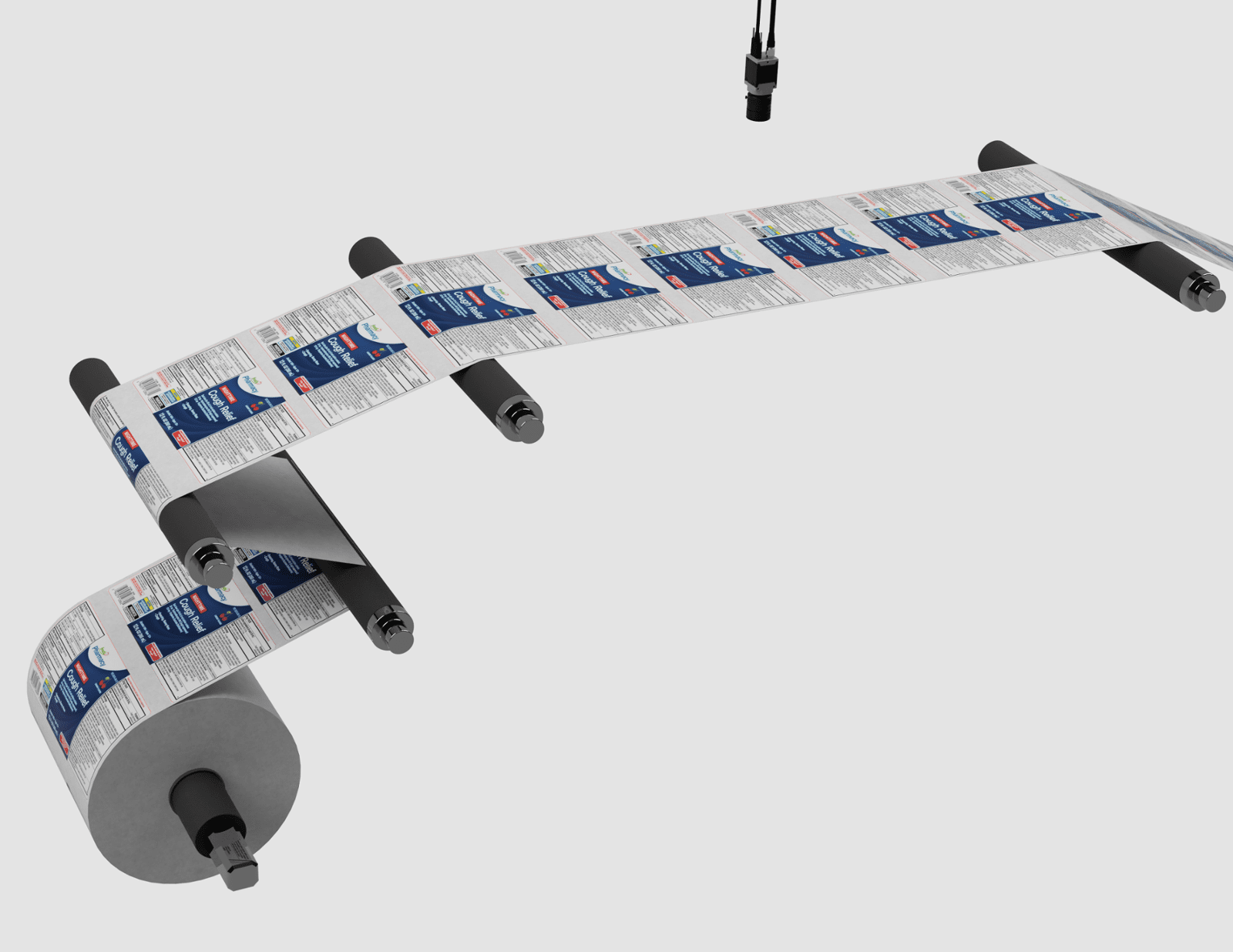

Label Surface Inspection

Inspection of label sheets to identify defects as small as 0.09mm.