Return on Investment Calculator

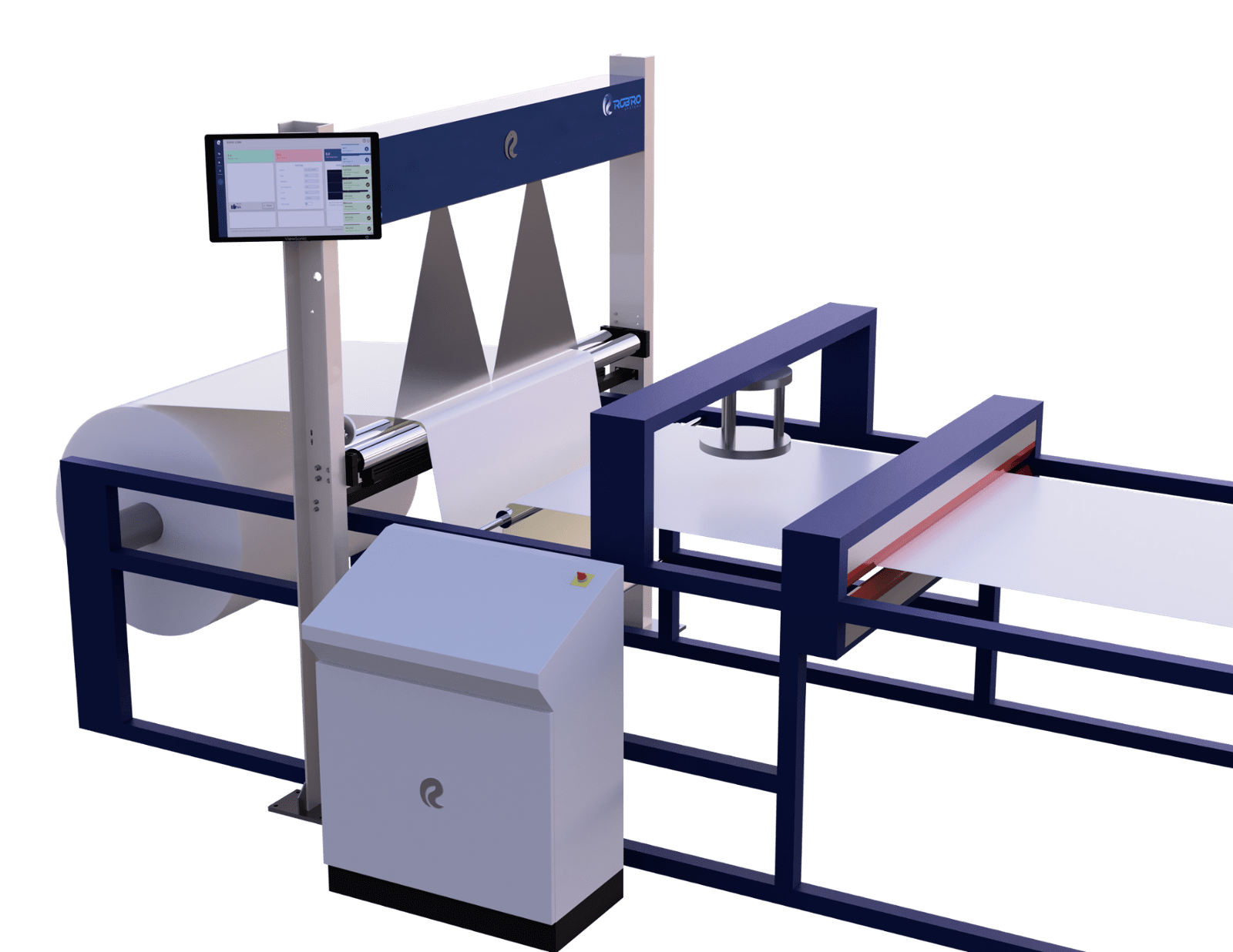

Wastage is reduced by 65% and with other benefits, ROI is returned within 15 months.

KWIS for FIBC - ROI Calculator

In INR ₹

In USD $

In INR ₹

In USD $

Beyond the Numbers: Exploring the Intangible ROI of Kiara

Your Investment in AI-enabled, Machine Solutions is going to pay you back and earn even more.

Improved Product Quality

Data Driven

Decisions

Reduced

Waste

Time Savings & Productivity

Streamlined Production Processes

Competitive Advantage