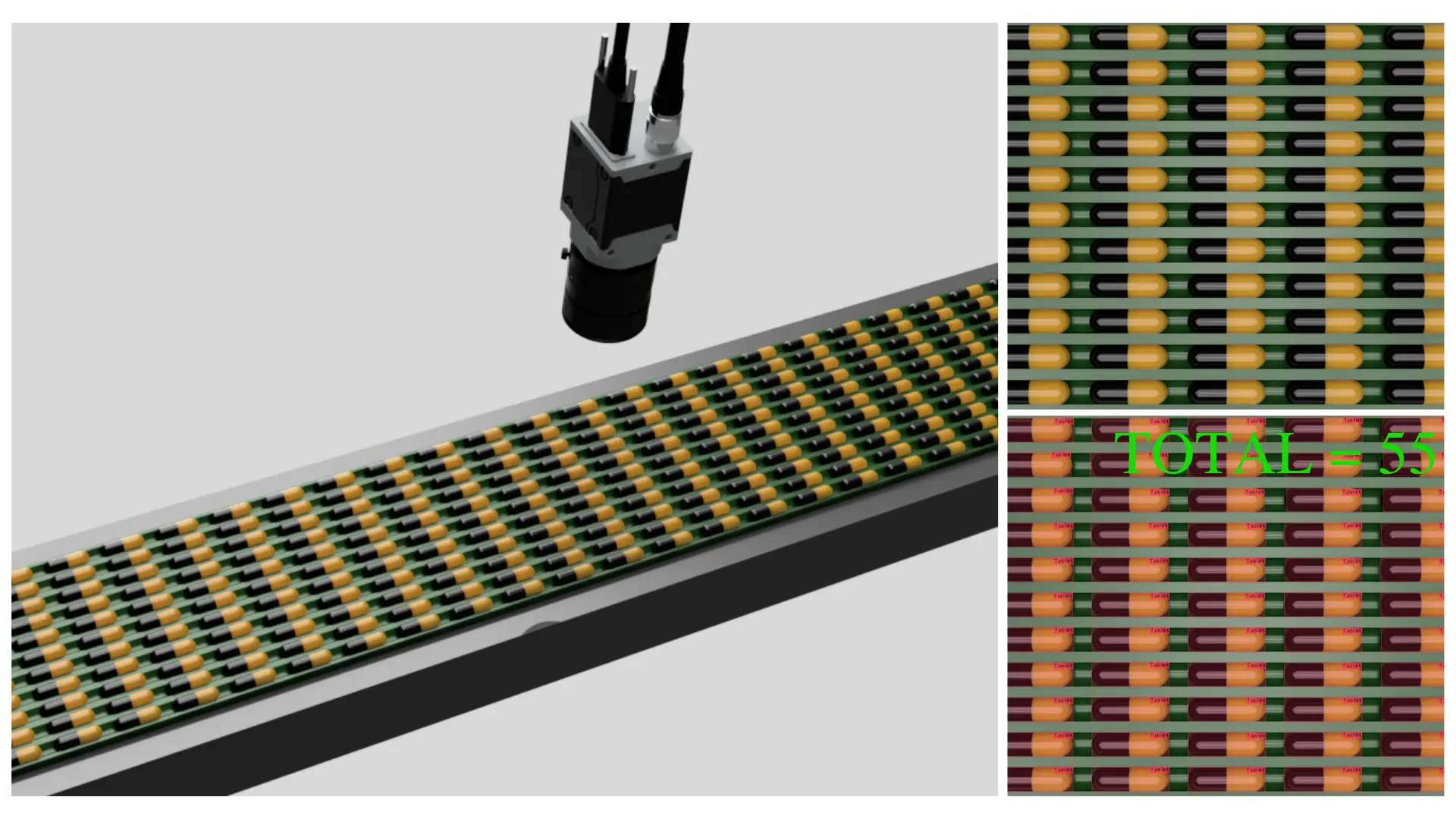

In pharmaceutical manufacturing applications, quality is always the top concern. Stringent regulatory standards mean high levels of liability for errors in production. Machine Vision plays a major role in delivering consistent high-quality products in the pharmaceutical industry, but machine vision can also deliver productivity gains, within the confines of high quality demands.

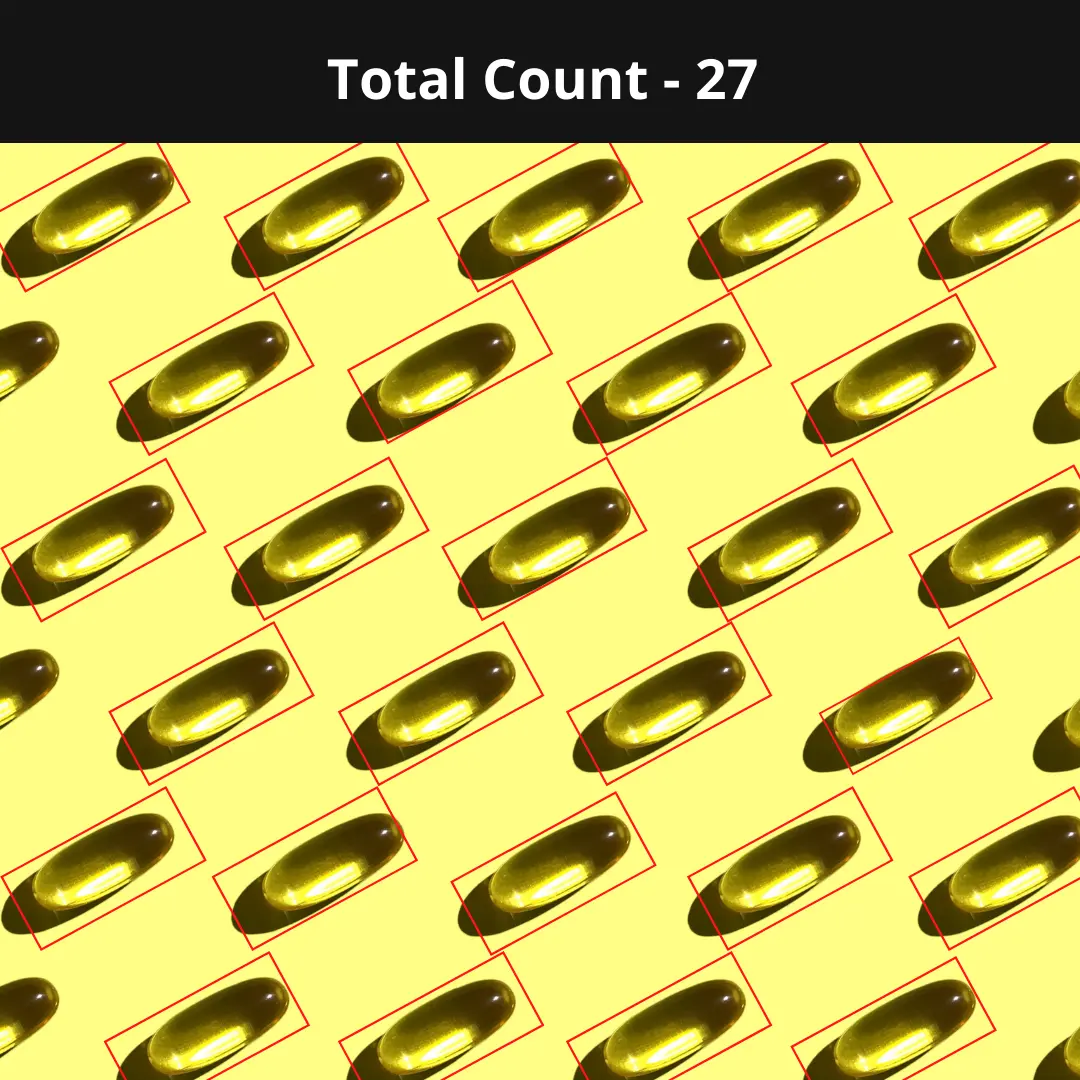

One of the primary adopters of Machine Vision Inspection and Quality Control in Medicine and Pharmaceutical Industry has trusted machine vision to deliver high-end product quality at the highest speeds possible. Along with the evolution of the Pharmaceutical Industry, Machine Vision has also evolved technologically displaying usability in the manufacturing, shipping, and data processing domains with automatic inspection, sorting, counting and error-proofing.

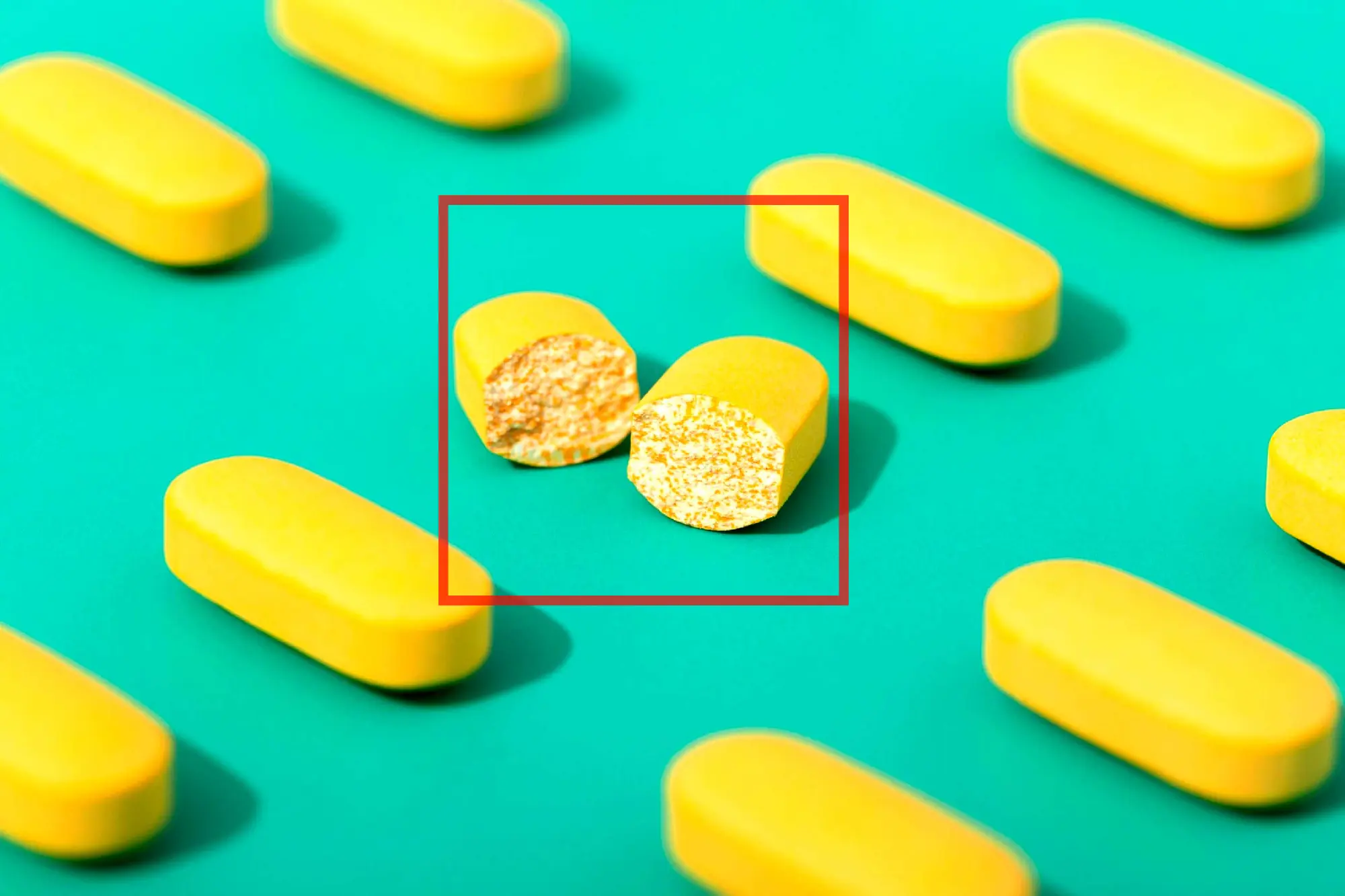

Machine Vision Systems has automated different sorts of operations. Machine Vision can solve many quality control problems in the pharmaceutical industry.

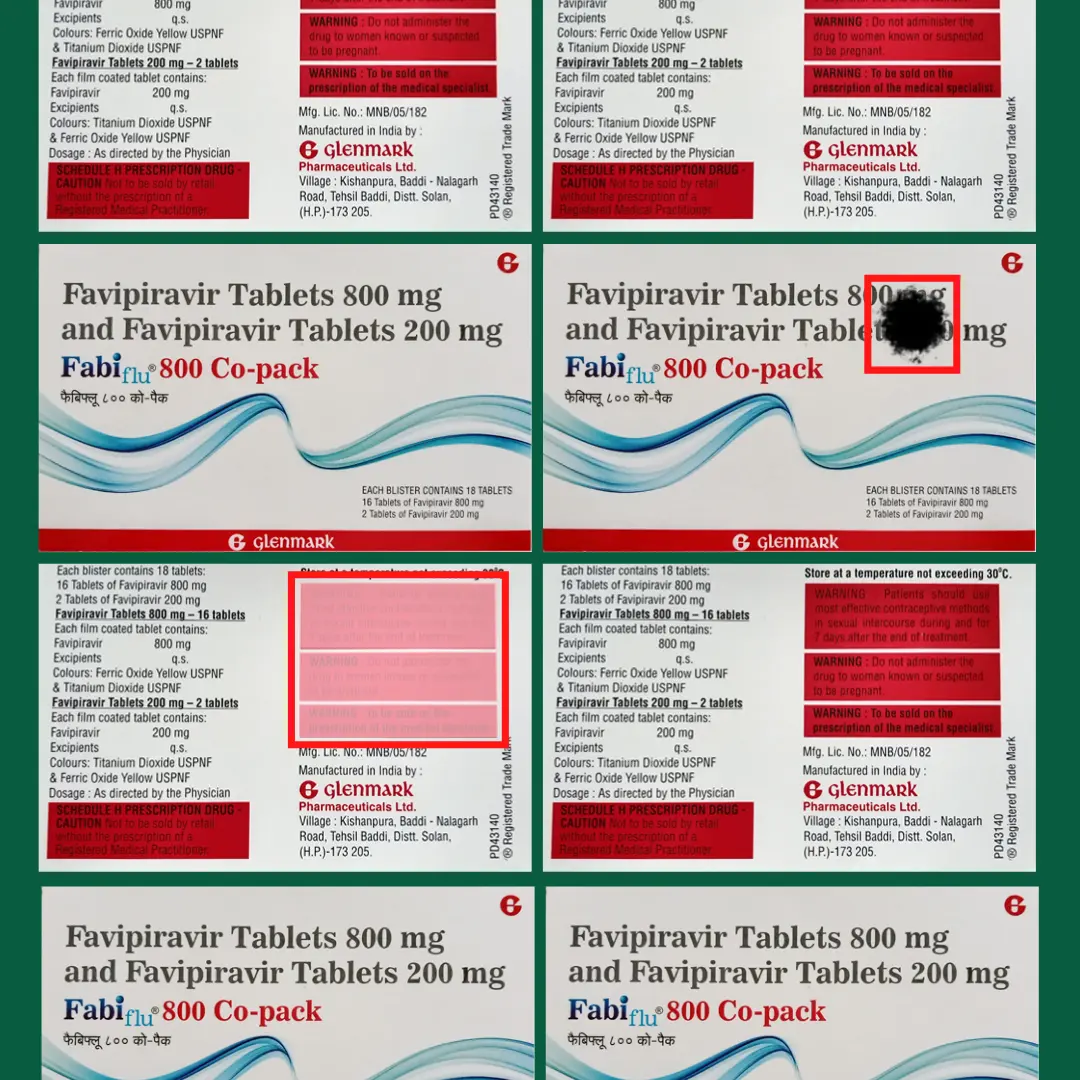

Label Print Defects

Label Print Defects

Labels on medicine bottles/jars carry important information. Kiara Vision Systems inspects such information with high precision

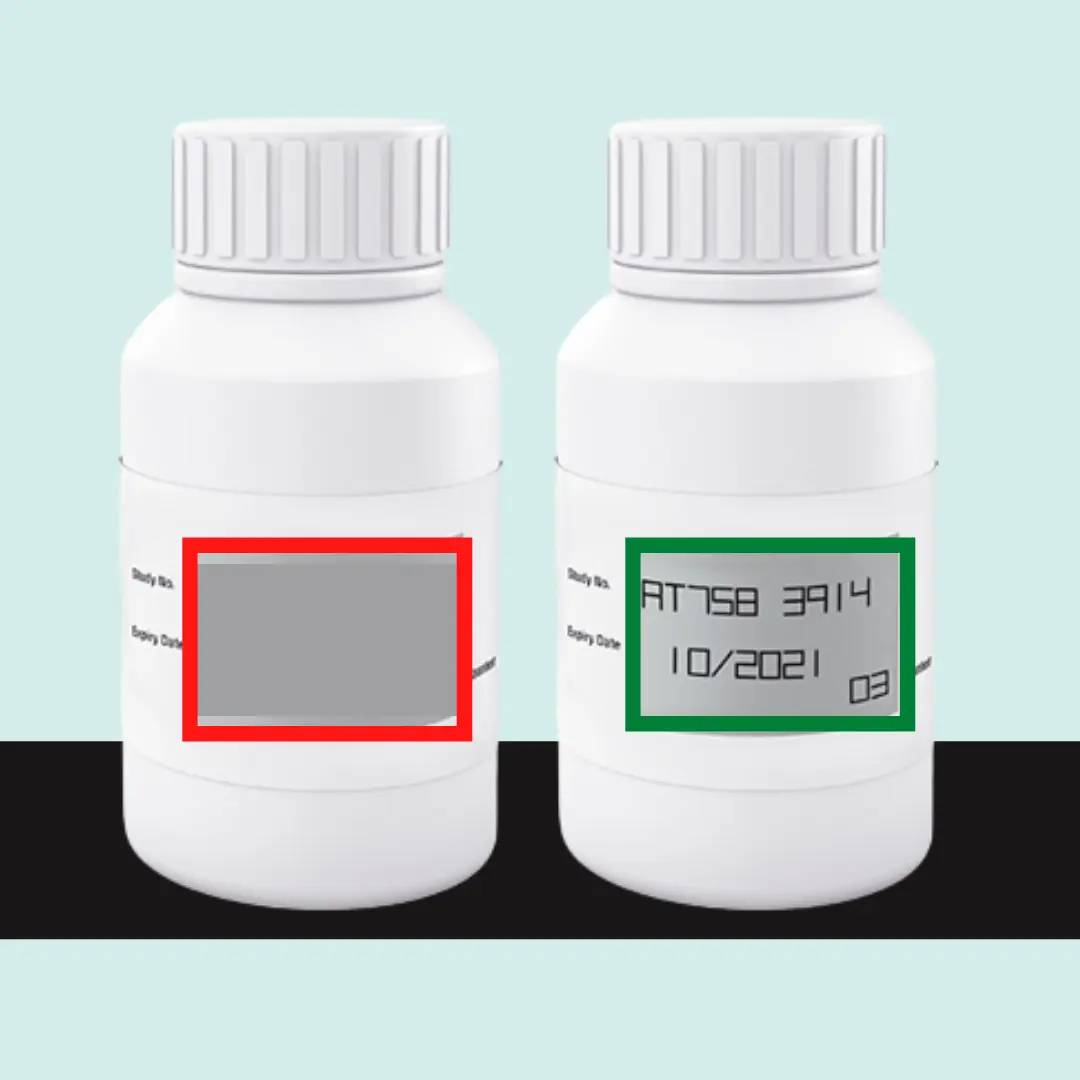

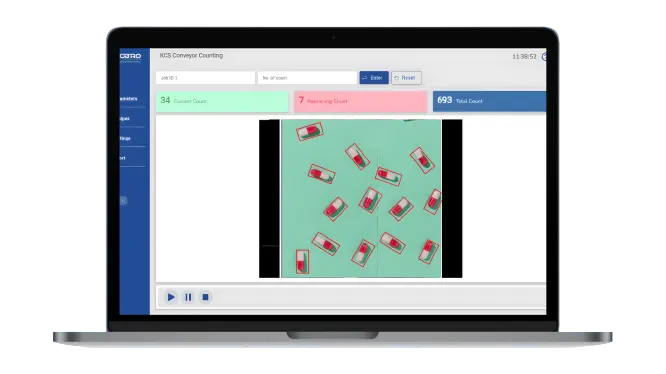

Expiry Print Absence/Presence

Expiry Print Absence/Presence

Expiry date is one on the most information present on any product. Never miss an expiry print with KVS.

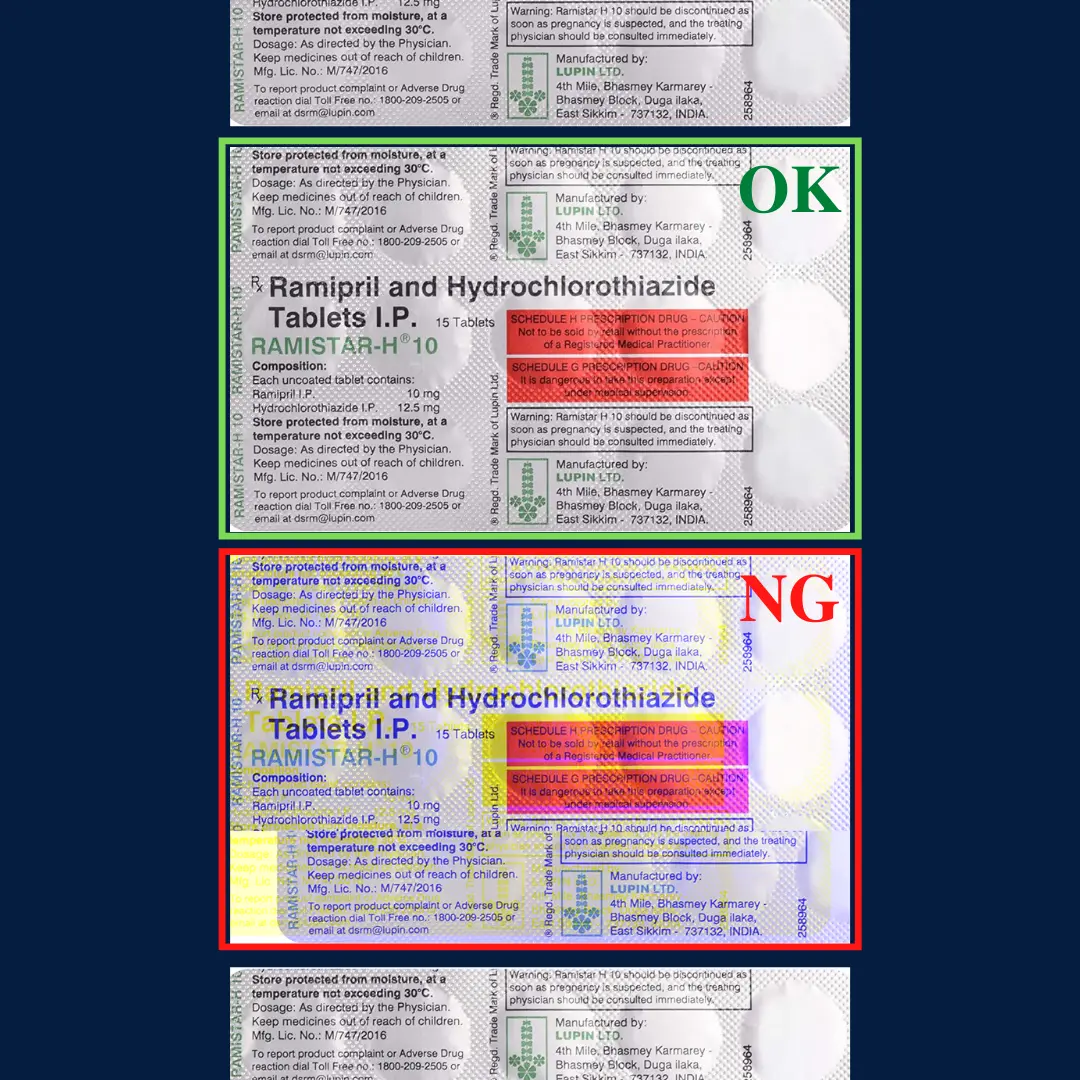

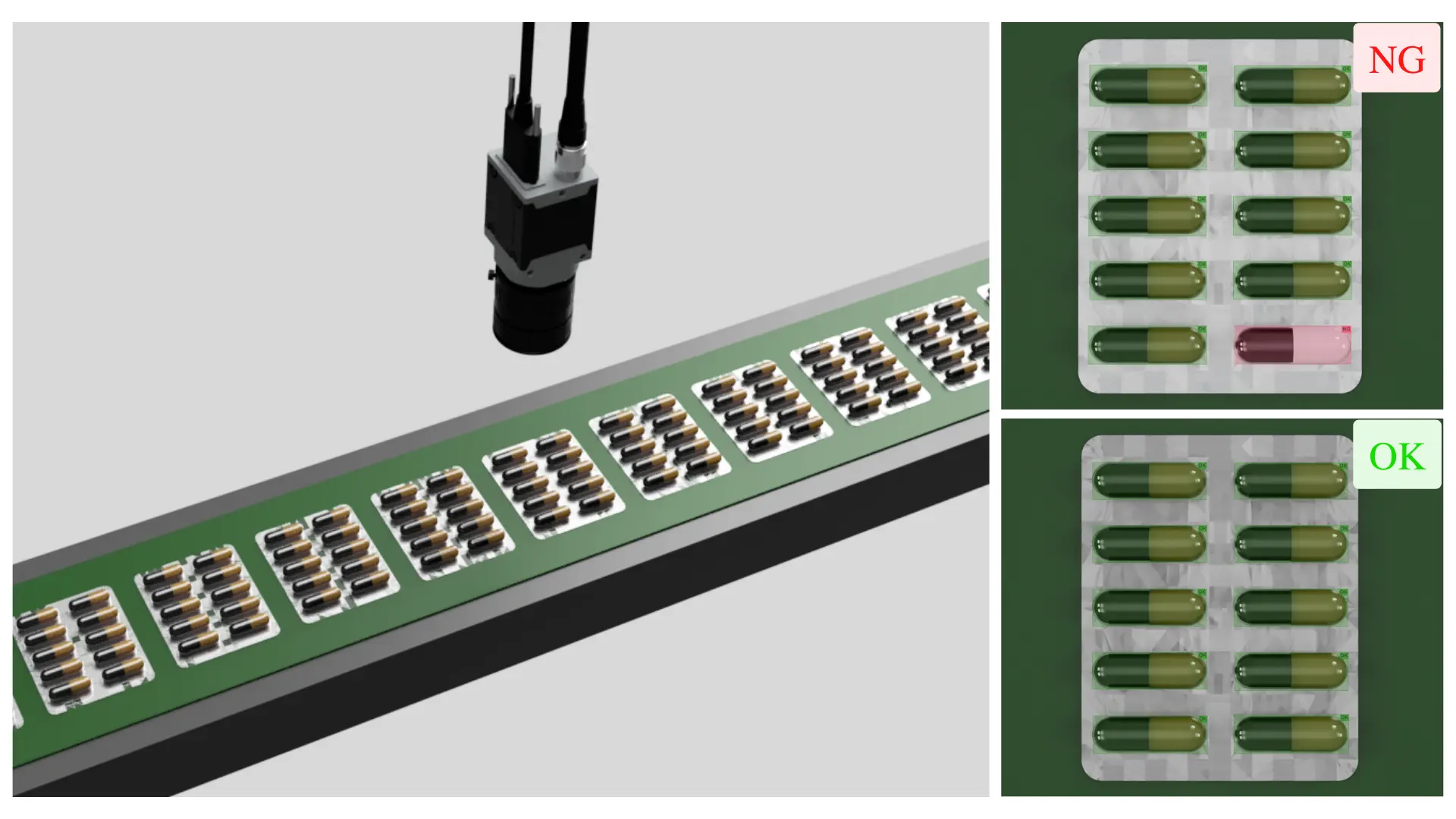

Mislabeled Blisters

Mislabeled Blisters

The information on the blister packs carries high regards. Kiara Visual Inspection and Sorting systems ensure all the information you want is there.