Defects in the Printing Process

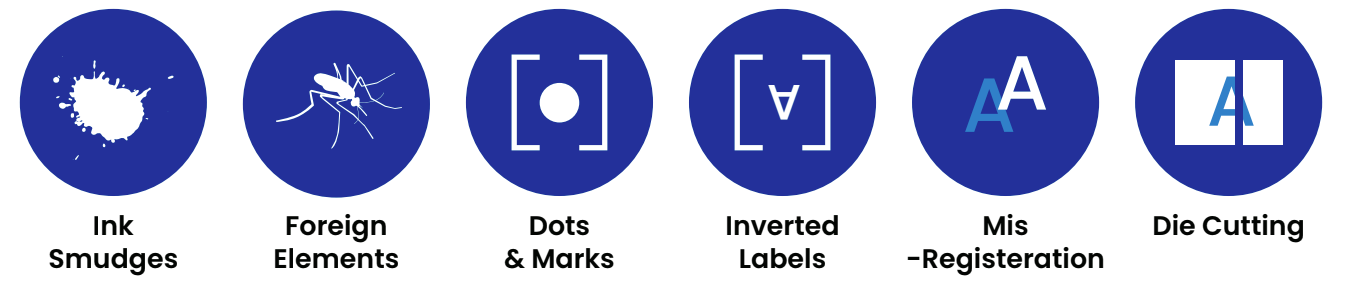

Printing is a complex process, and its quality depends on several factors. Machine settings, environmental conditions, raw material quality play significant roles in print quality, to name a few. Mislabels, smudged text, missing prints, dots, and marks are recurring incidents of the printing world. These defects not only create room for misunderstandings and misinformation but are also responsible for frequent customer rejections and diminish the brand value. Print Quality inspection is an important step that can save your factory from all that hassle. So if you're looking for a faster, easier, and accurate way for Print quality inspection, Robro Systems congratulates you. You have come to the right place!

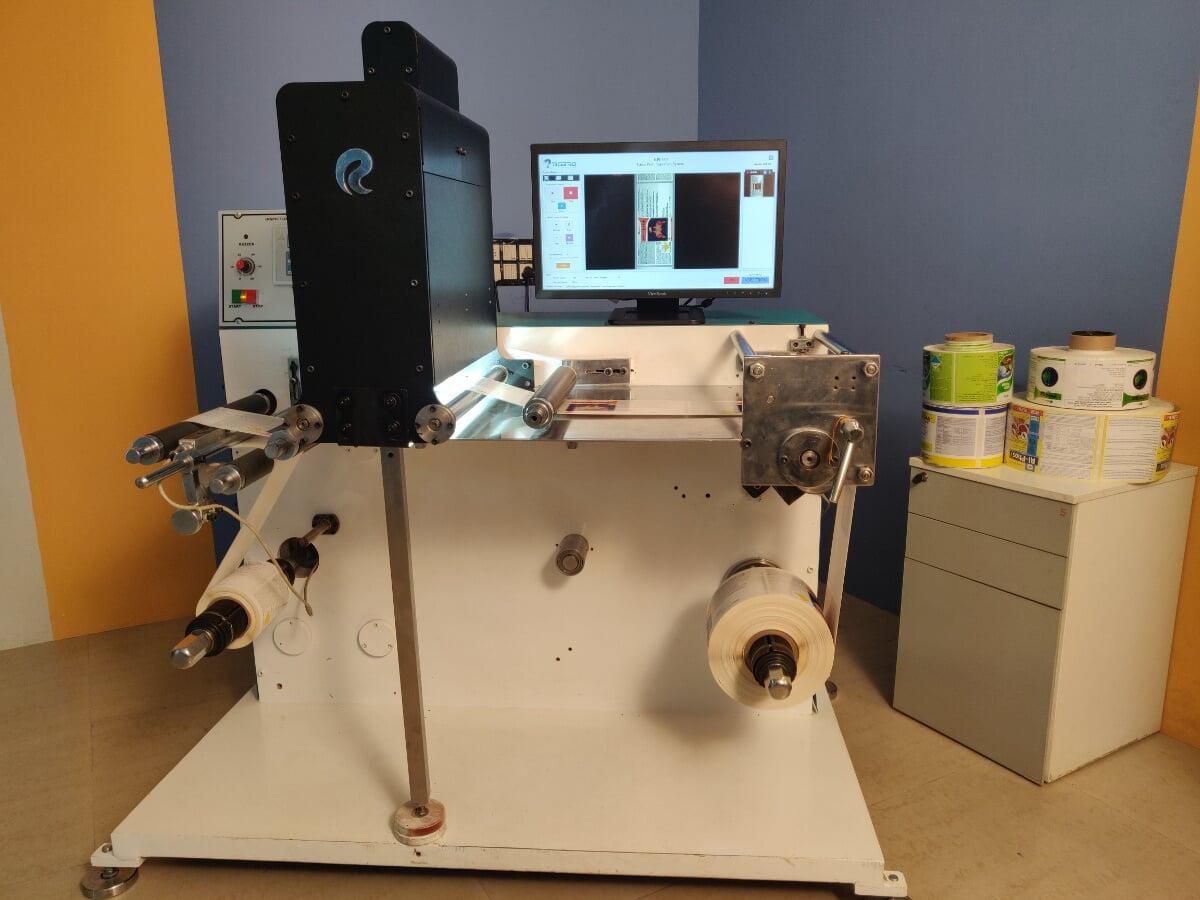

KPI-330 in action

The KPI-330 Advantage

We provide one of the best automatic print quality inspection systems. We have merged AI and camera vision to develop - 'Kiara' Print Inspection (KPI-330), a machine that effortlessly performs inspection in plastic print quality, expiry date print, label print, packaging print, and much more. Kiara Print Inspection (KPI-330) is the first indigenous 100% Visual Inspection System for Label Rolls. An automatic print defect detection system can find defects as small as 0.09mm at a speed of more than 200 meters/minute.

Experience the accuracy and efficiency of Industrial Automation, Contact us Now!