Irrespective of the industry, consumer products manufacturers must prioritise accuracy, customer satisfaction, and quality assurance. When the processes are efficiently handled, products are apportioned and packed correctly, which prevents expensive errors and reputation damage.

Some manufacturing and packaging companies traditionally have used weight-based packing. Sometimes, this long-accepted technique may reduce profits as manufacturers may add more products. Lesser weight can also negatively impact brand reputation, which is another reason manufacturers may pack more products.

An alternative that is gaining popularity is the automatic counting and packing machine, which guarantees 100% accuracy. This alternative not only ensures exact control, leading to higher customer satisfaction but also improves ROI due to lower wastage and/or extra products.

Limitations of

Packing by Weight

Companies selling large product quantities require accurate and quick sorting, quantity apportioning, and packing methods for maximum efficiency and quality control. An important decision for such companies is choosing whether to pack products as per count or weight. This is an important decision and depends on the type of products and can significantly impact revenue and profits and customer satisfaction.

Some manufacturers may opt for packing individual products as per their weights but there may be some potential issues with this option. The commonest issue is inaccurate quantities because each product is not of the exact same weight. For example, items like fish fingers or nuggets have minor weight variances from one piece to another. Packing these as per their weight can result in under or overcounts. Individually, the impact may appear to be insignificant; however, when multiplied by thousands or millions, it can result in a huge impact.

Depending on the nature of miscounting, overcounting can impact profits sizably. Undercounting can cause customer dissatisfaction and negatively impacts the company’s reputation, which can further impact sales as consumers move to competitor products. Undercounting may impact sales while overcounting affects profitability.

Packing based on

Product Count

For products with minor weight variations, packing based on the number of products is cost-effective, efficient, and precise when compared with weight-based packaging. Automatic product counting machines ensure the net contents in each package are 100% accurate. This prevents wastage due to over or undercounting, product loss, and maximum efficiency.

Some companies may consider installing automatic counting machines as an expensive investment. However, the amount manufacturers can potentially save by achieiving 100% accuracy and avoiding wastage ensures recouping the investment quickly.

On the other hand, when customers receive a lesser number of products, they simply move to a competitor, which can significantly impact sales and profitability. Automatic counting packing machines ensure every package has the same number of products eliminating customer dissatisfaction.

On the other hand, when customers receive a lesser number of products, they simply move to a competitor, which can significantly impact sales and profitability. Automatic counting packing machines ensure every package has the same number of products eliminating customer dissatisfaction.

Benefits of Vision-based Counting and Packing Machines

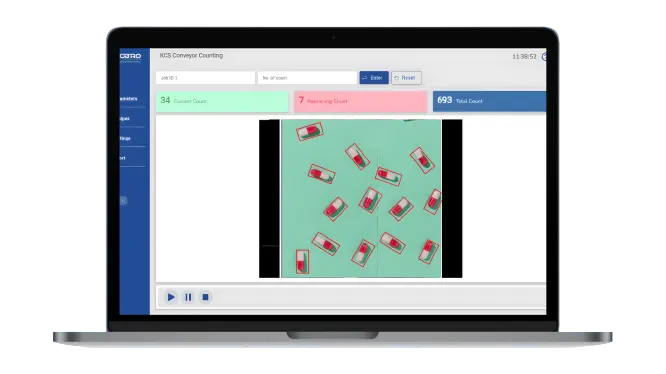

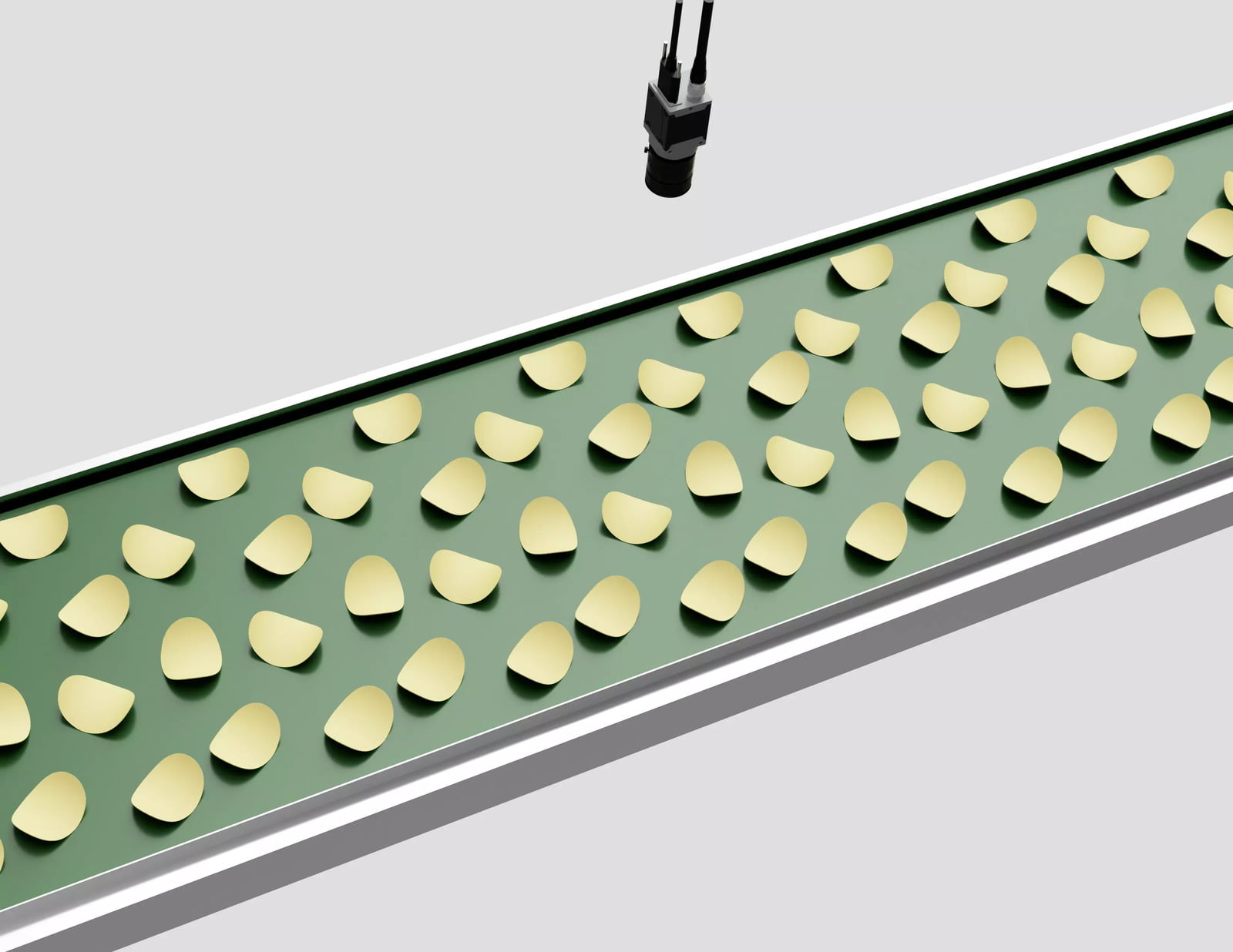

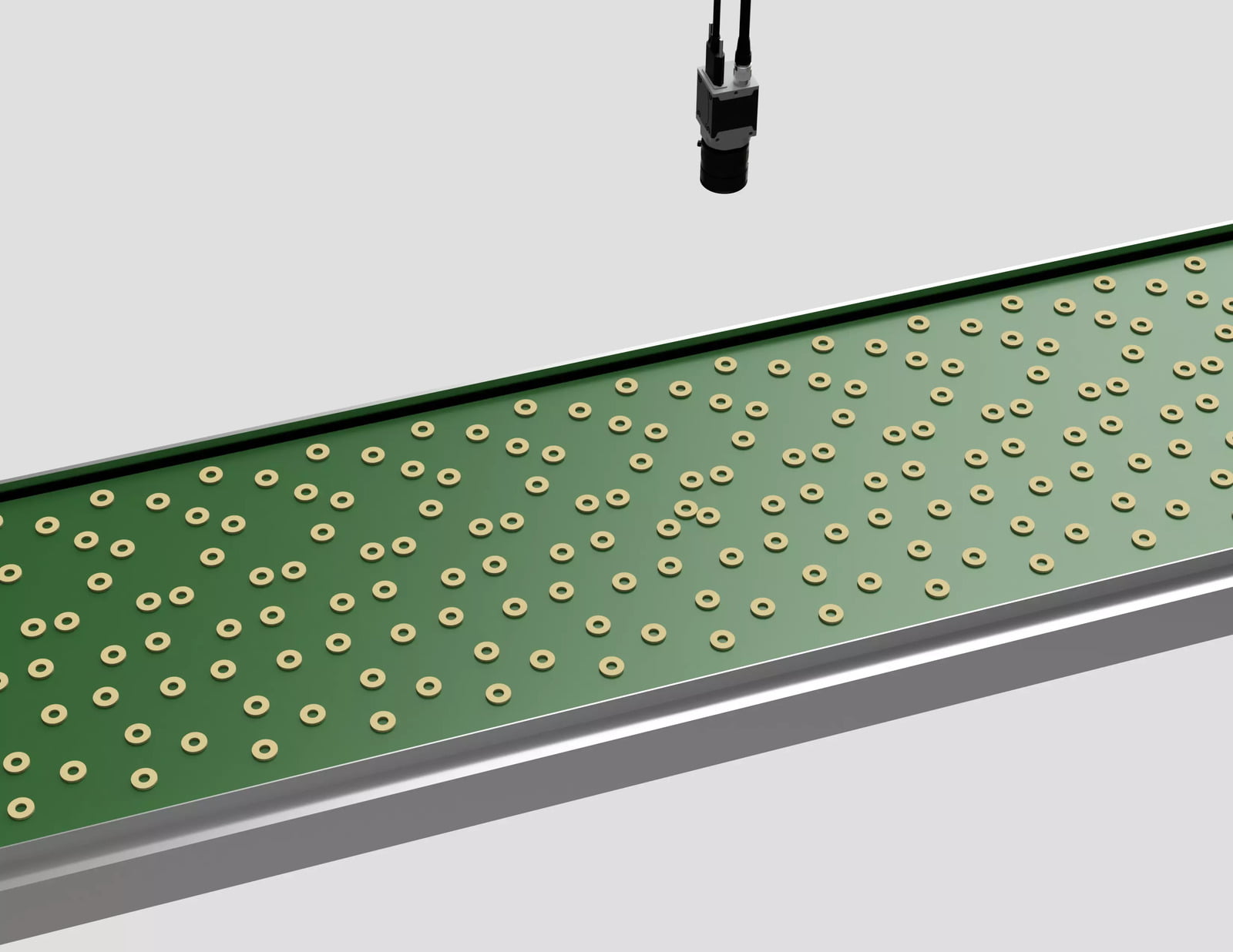

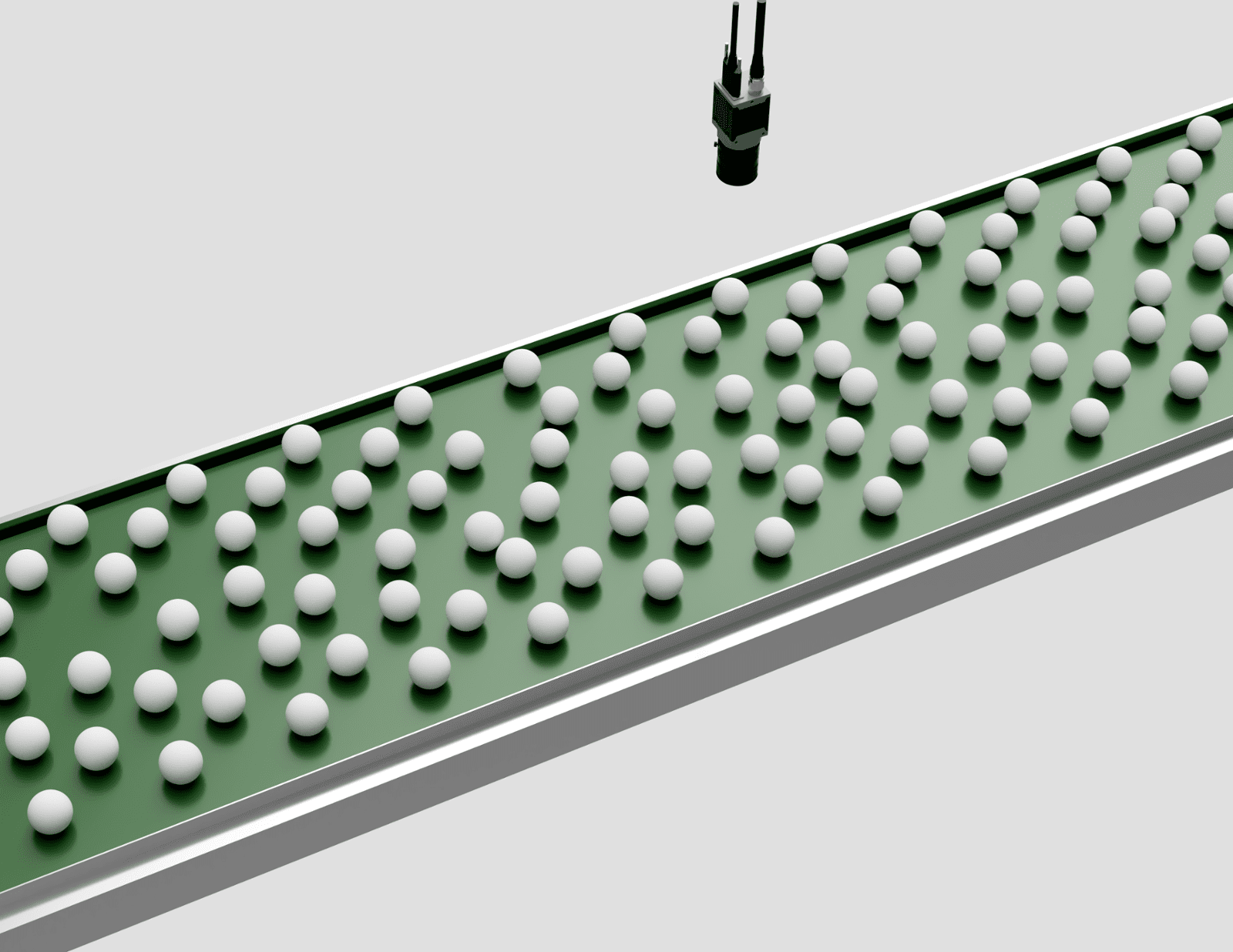

Robro Systems uses a high resolution industrial camera to capture images of products as they move on the conveyor belt. It captures high-resolution images, and the system’s deep-learning library identifies each product and counts it. To know more about our automatic counting and bagging machine that provides 30% faster counting 100% accuracy, and 50% less labor, book a demo today.