In technical textile manufacturing, even a small defect can lead to major financial losses. Rejected export shipments, downgraded fabric grades, customer complaints, and production downtime often have one common root cause — undetected fabric defects.

For manufacturers in FIBC, PP woven, automotive, filtration, medical, and other technical textile segments, maintaining consistent quality is critical. However, certain recurring defects continue to impact profitability year after year.

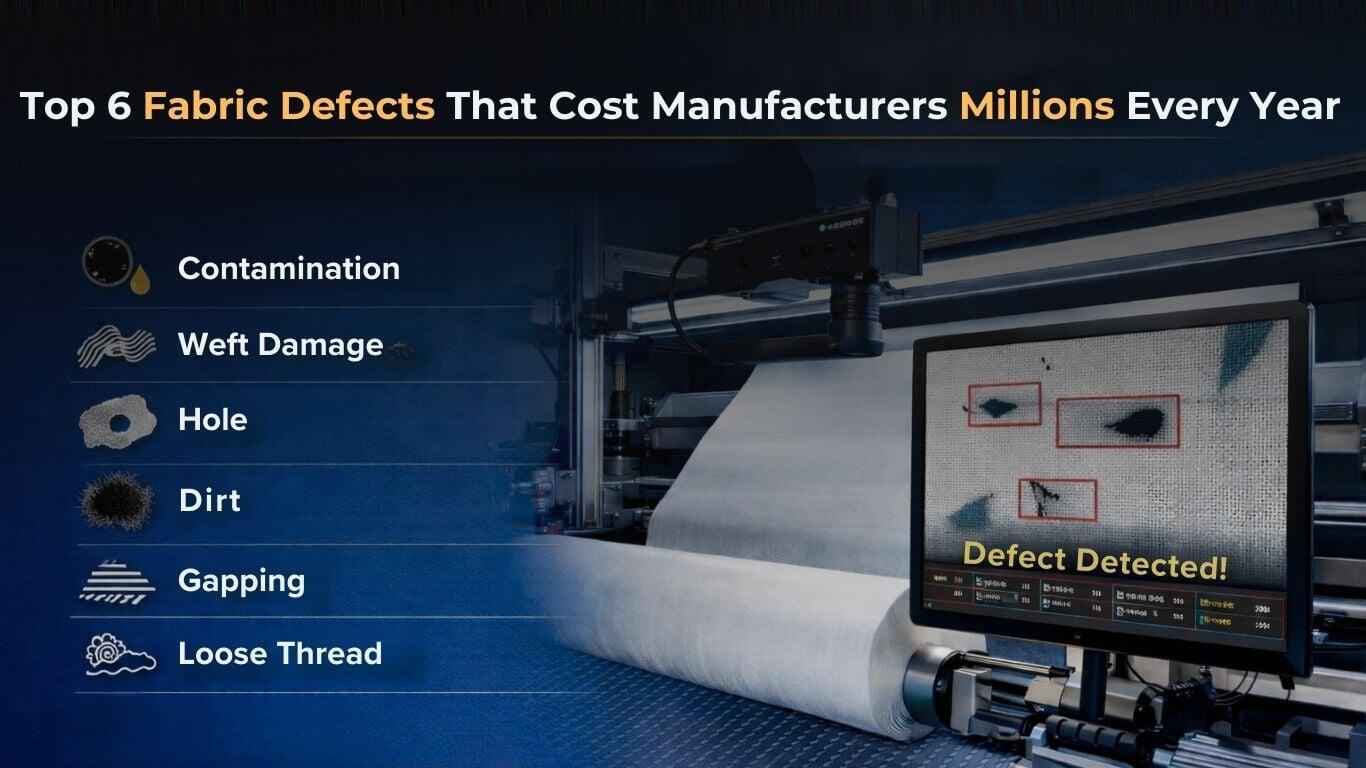

Here are the six most common and costly fabric defects every manufacturer must control.

1. Contamination

Contamination refers to the presence of foreign particles within the fabric structure. These may include oil stains, dust particles, colored fiber contamination, polypropylene lumps, or external debris.

Why it happens:

Raw material impurities

Poor housekeeping

Oil leakage from machinery

Environmental exposure during production

2. Weft Damage

Weft damage occurs when the horizontal yarn (weft) is broken, misaligned, or missing during weaving.

Why it happens:

Improper yarn tension

Loom malfunction

High-speed weaving inconsistencies

Yarn breakage

Impact on manufacturers:

Weft damage reduces tensile strength and affects structural performance. In load-bearing applications such as FIBC or automotive textiles, this defect can compromise safety and durability, leading to costly claims.

3. Hole

A hole is a visible opening or puncture in the fabric structure.

Why it happens:

Yarn breakage

Mechanical abrasion

Needle damage

Excessive tension or handling errors

Impact on manufacturers:

Holes are among the most critical defects. Even a single hole can lead to immediate rejection, especially in packaging and industrial fabrics. In heavy-duty applications, it may cause product failure during usage.

4. Dirt

Dirt appears as surface stains or dark marks on fabric.

Why it happens:

Inadequate cleaning

Dusty production environments

Oil leakage

Operator handling

Impact on manufacturers:

Although often considered minor, dirt significantly affects visual quality. Premium-grade fabrics may be downgraded, reducing overall profitability.

5. Gapping

Gapping refers to abnormal spacing between yarns, creating visible gaps in the fabric structure.

Why it happens:

Uneven warp tension

Improper weaving settings

Yarn density inconsistencies

Impact on manufacturers:

Gapping affects fabric strength, uniformity, and appearance. In coated or laminated fabrics, it can impact bonding quality and barrier performance.

6. Loose Thread

Loose thread defects occur when yarn ends protrude from the fabric surface or are not properly secured.

Why it happens:

Improper trimming

Incomplete weaving cycle

Yarn breakage not properly managed

Impact on manufacturers:

Loose threads affect aesthetic quality and may lead to further fabric damage during processing. In export shipments, this defect often results in visual rejection.

The Hidden Cost of Fabric Defects

The cost of these defects extends beyond scrap material. Manufacturers also face:

Re-inspection labor

Production downtime

Delivery delays

Customer penalties

Brand credibility damage

Even a small percentage of undetected defects can significantly impact annual revenue in high-volume textile production.

Why Traditional Inspection Is No Longer Enough

Manual inspection methods rely heavily on human observation. At modern production speeds, small defects such as contamination spots, gapping, or loose threads can easily go unnoticed.

Human inspection also introduces inconsistency due to fatigue and subjectivity.

To maintain global quality standards, textile manufacturers need real-time, data-driven inspection systems.

Moving Toward Intelligent Fabric Inspection

AI-based machine vision systems enable continuous, real-time defect detection during production. Instead of identifying issues after completion, manufacturers can detect and correct defects immediately.

With advanced inspection systems, manufacturers can:

Reduce rejection rates

Minimize rework

Improve material utilization

Generate actionable defect analytics

Maintain consistent quality standards

Robro Systems supports technical textile manufacturers in implementing AI-driven fabric inspection solutions designed specifically for high-speed production environments.

Conclusion

Contamination, Weft Damage, Hole, Dirt, Gapping, and Loose Thread are not minor quality concerns — they are profitability risks.

Manufacturers who proactively detect and control these defects will not only reduce losses but also strengthen customer trust and long-term competitiveness.

In today’s technical textile market, quality control is no longer optional — it is strategic.