Like several other digital technologies, machine vision (MV) is an important component driving Industry 4.0. The high volume of data accessed via visual equipment is able to quickly detect faulty products by recognizing defects, thereby enabling efficient and rapid intervention in Industry 4.0.

The different versions of MV improve production efficiency and have diverse applications in quality control, inventory management, and more. The elimination of human errors prevalent in manual inspections reduces mistakes, thereby enhancing productivity and profitability.

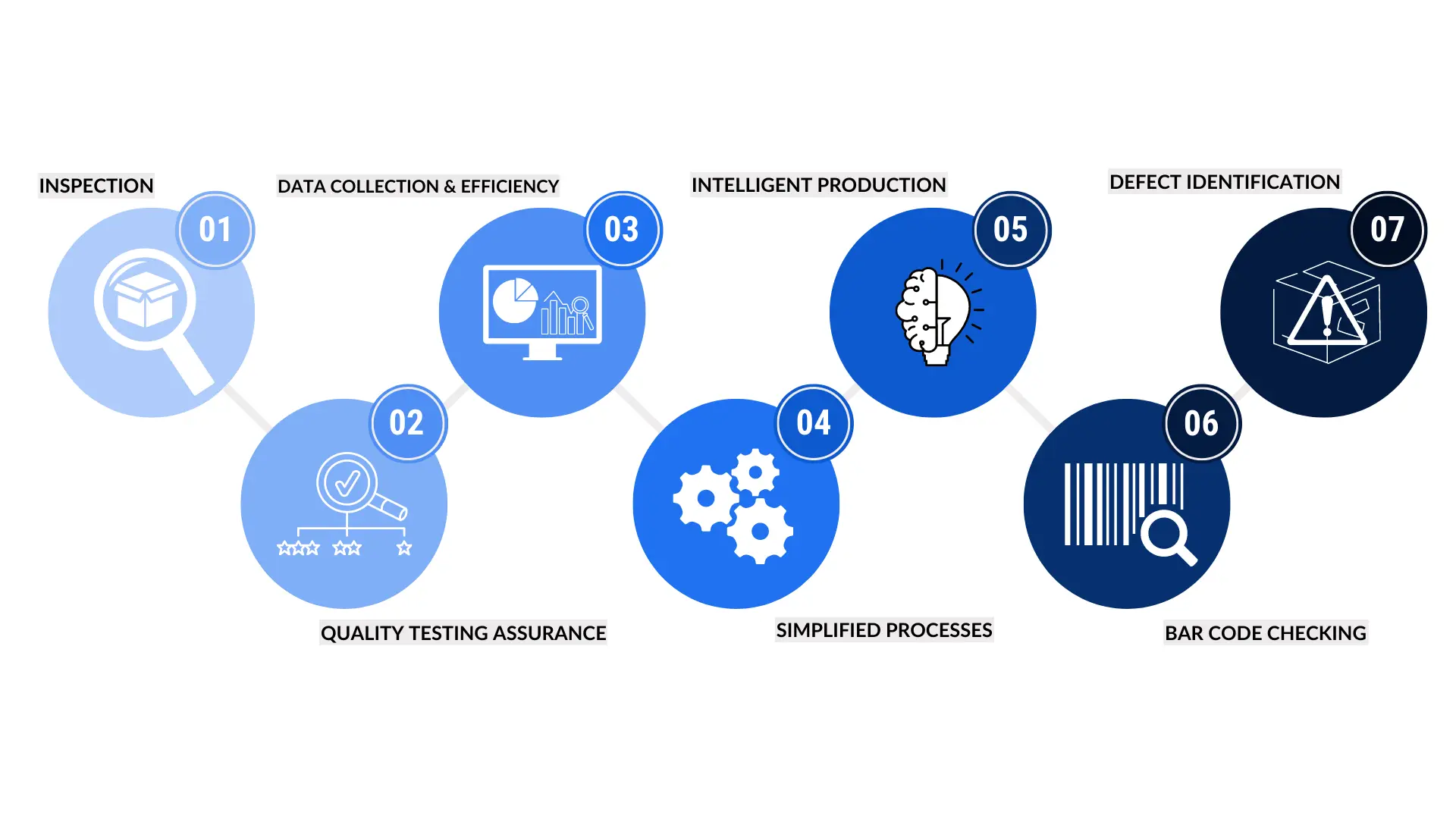

Here are several applications of machine vision in Industry 4.0 :

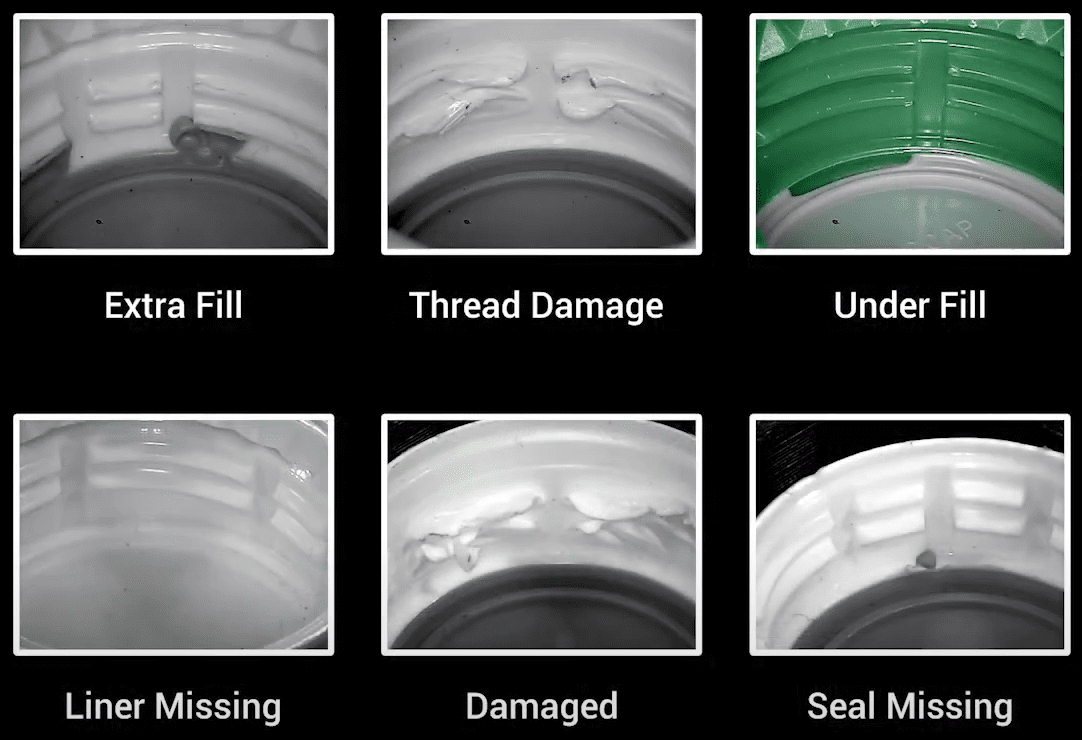

1. Inspection

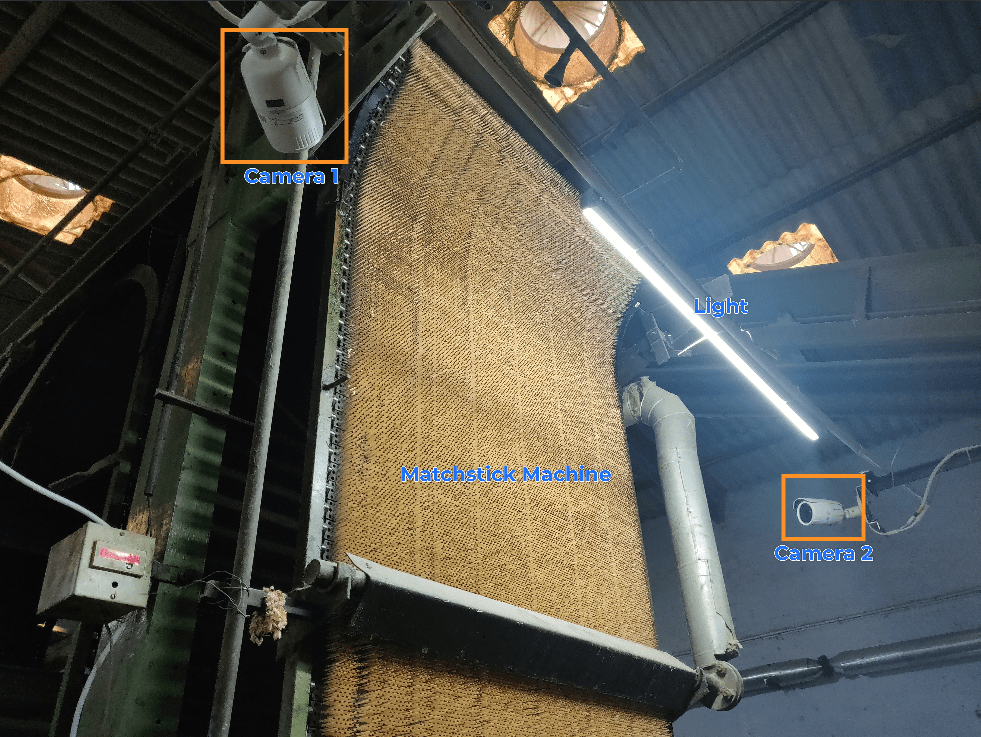

MV is quicker, objective, can work without any breaks and is ideal for repeated and accurate inspections. Manufacturing companies can save money and increase profits by reducing errors. It also enables companies to meet regulatory compliances, reduce returns, and monitor even small parts. While creating an MV system, essential factors like the direction of the light, its wavelength, and magnitude must be taken into consideration.

2. Quality testing and assurance

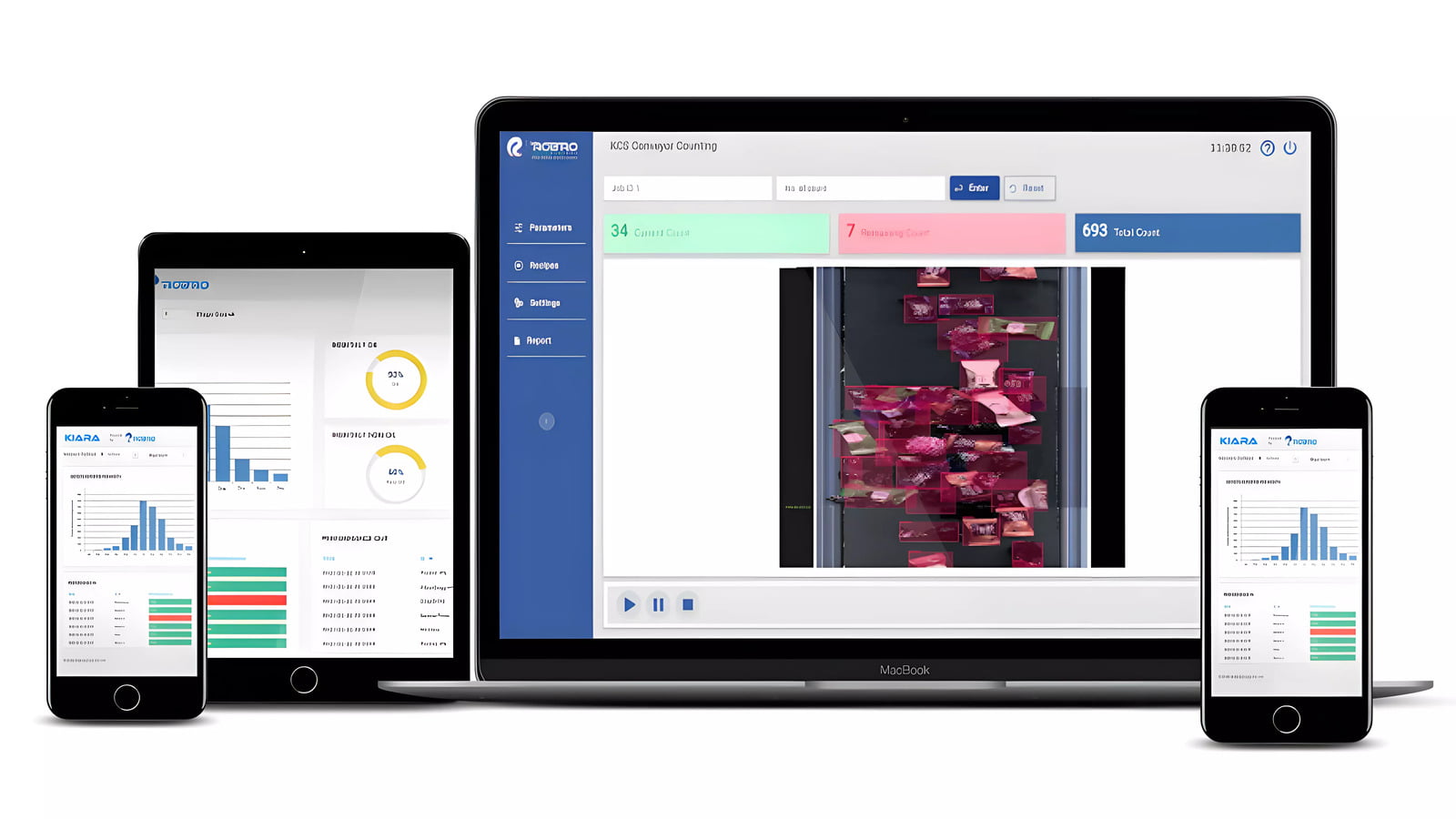

MV is able to automate quality testing, which simplifies the process and improves the results. These systems use advanced technologies and high-tech cameras to ensure the quality and precision of products thereby decreasing loss due to materials wastage. Industry 4.0 adopts an integrated approach allowing computers to analyze the data collected using the MV systems, which results in informed decision-making thereby decreasing the labor requirements and enhancing production efficiency.

3. Data collection and efficiency

Combining automated systems with MV increases the quality and quantity of data collected. This information can then be used to ensure quality, minimize wastage, and increase production capability and speed. Additionally, MV systems improve data sharing and provide beneficial information to production lines and inspection stations to reduce bottlenecks, overruns, and other disturbances.

4. Intelligent production

Deep learning is revolutionizing the impact of MV in industrial automation and intelligent production. Integrating deep learning autonomously enables MV systems to adapt to meet production variations. MV integrates machine learning to observe and view the production lines and surroundings that can deliver newer methods to conduct low-waste manufacturing with enhanced performance.

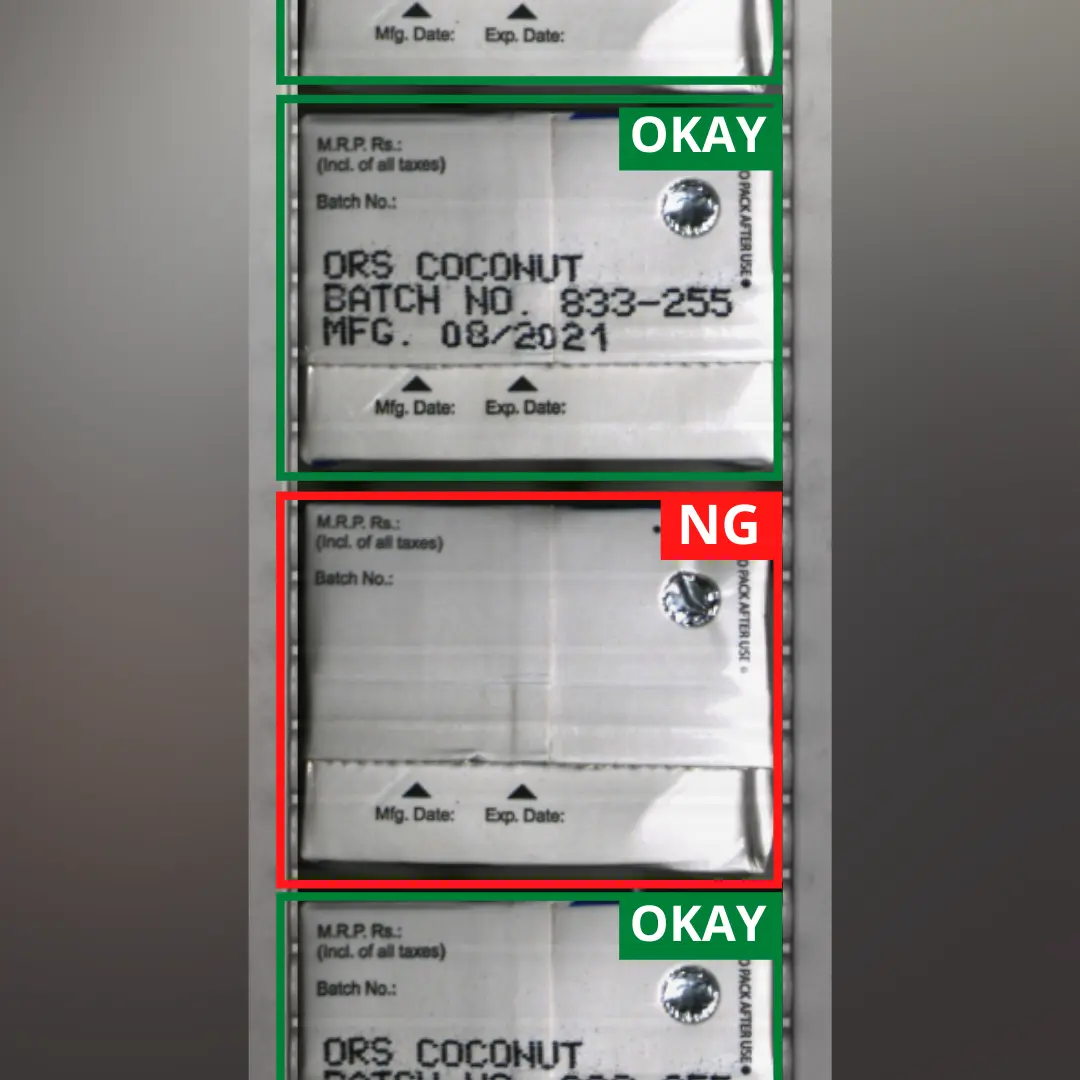

5. Simplified processes

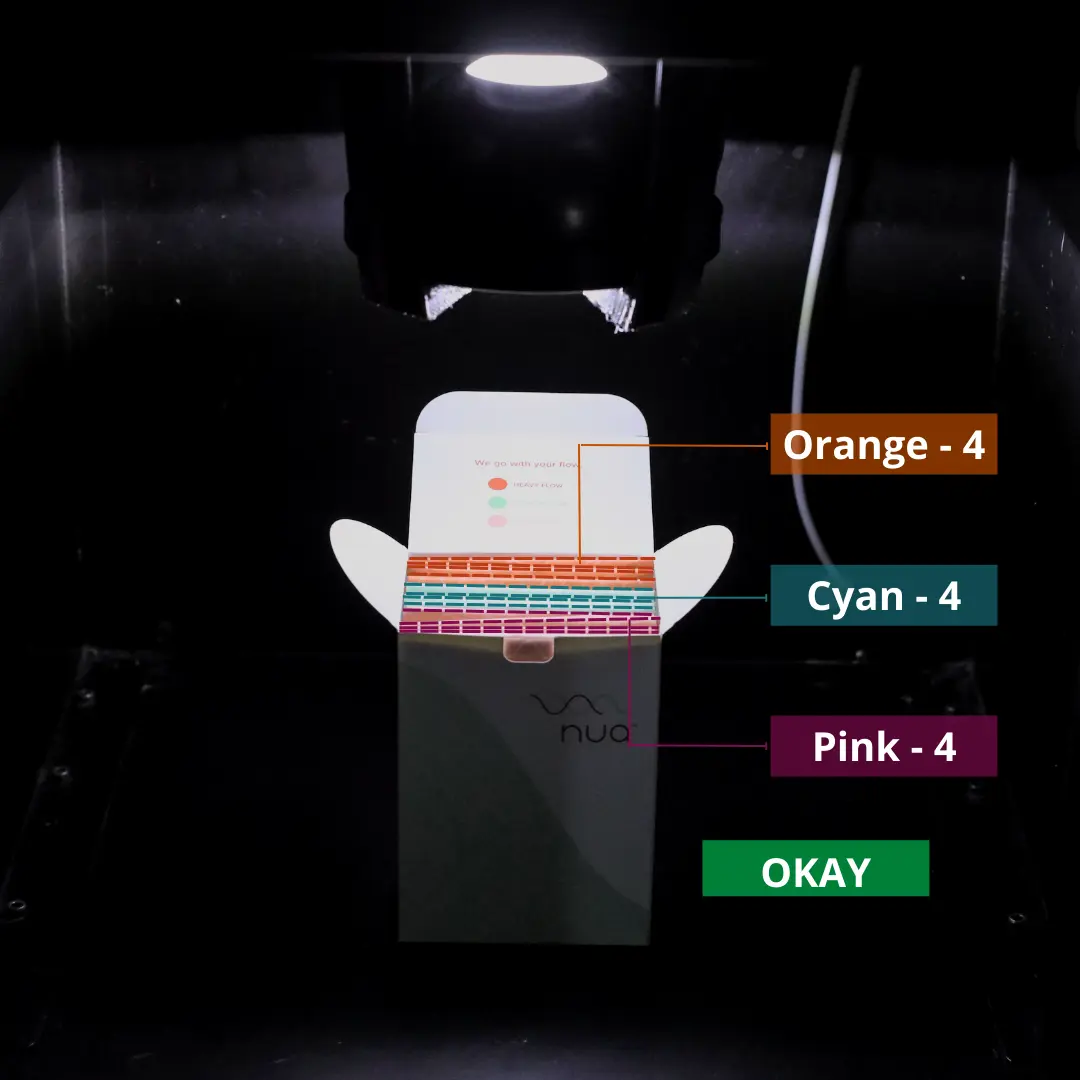

MV assists manufacturing companies to simplify processes where a large number of products have to be tested and inspected on the production lines. It automatically identifies any variations and is commonly applied for tooling and detailed placements on a production line. The identified anomalies are compared to existing data for defect detection in manufacturing companies.

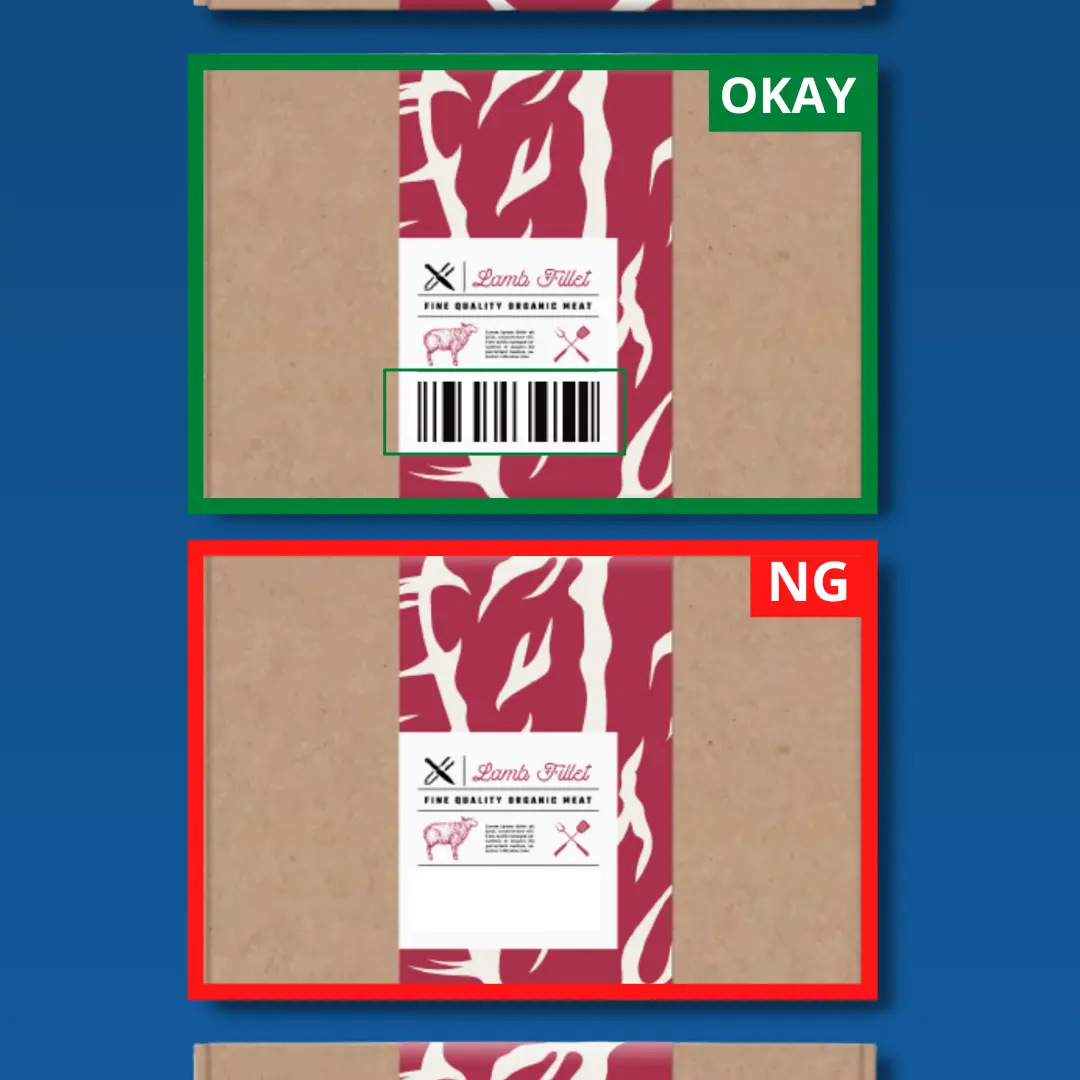

6. Bar code checking

Checking a large number of bar codes manually is time-consuming and prone to human errors and inaccuracy. MV systems can automatically and quickly check bar codes and identify defects. These systems can count stocks, maintain warehouse inventory status, and issue warnings on any abnormalities. The automated systems make inspection easier, maximize reading speed and make the production process accurate.

7. Defect identification

Manufacturing companies can identify defects using MV systems. Additionally, several machine vision companies offer devices that accurately verify the exact measurements of different materials and components. The MV systems capture high-end images that are analyzed by intelligent software to report any errors.

MV is implemented for automated visual inspection and is beneficial in overcoming several problems. The machine vision market is driven by the need for more reliable and efficient inspection systems that overcome the limitations of manual inspections. The latest technology provides precision and accuracy in the inspection of different types of products. These systems are crucial and beneficial for driving the Industry 4.0 revolution by enhancing the accuracy, productivity, and overall efficiency of manufacturing companies.