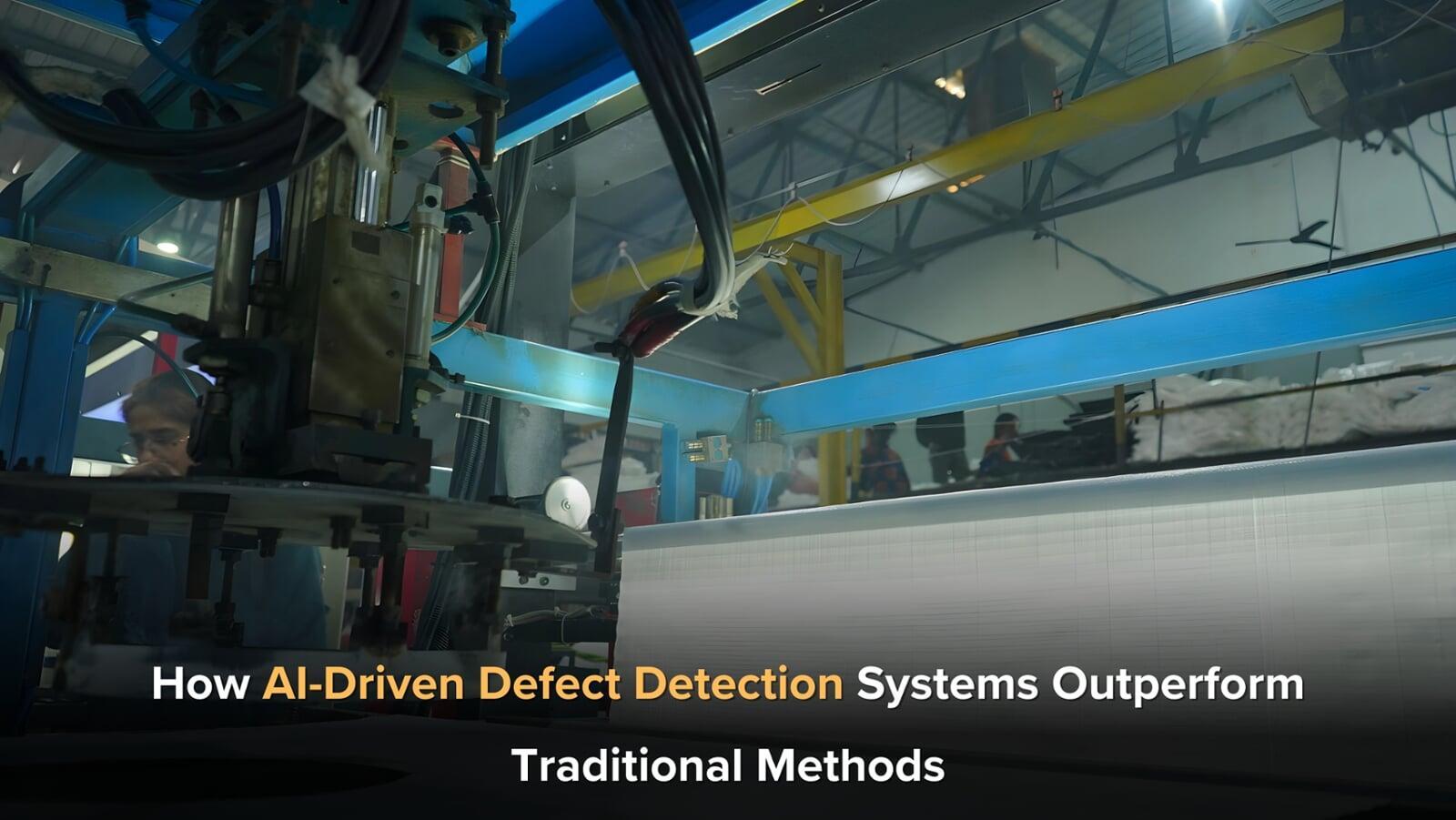

Glass fibre fabric production operates under continuous movement, high tension, and strict quality requirements. In such environments, defects are not exceptions — they are process-driven occurrences. What determines product quality is not the absence of defects, but the ability to identify and cont...