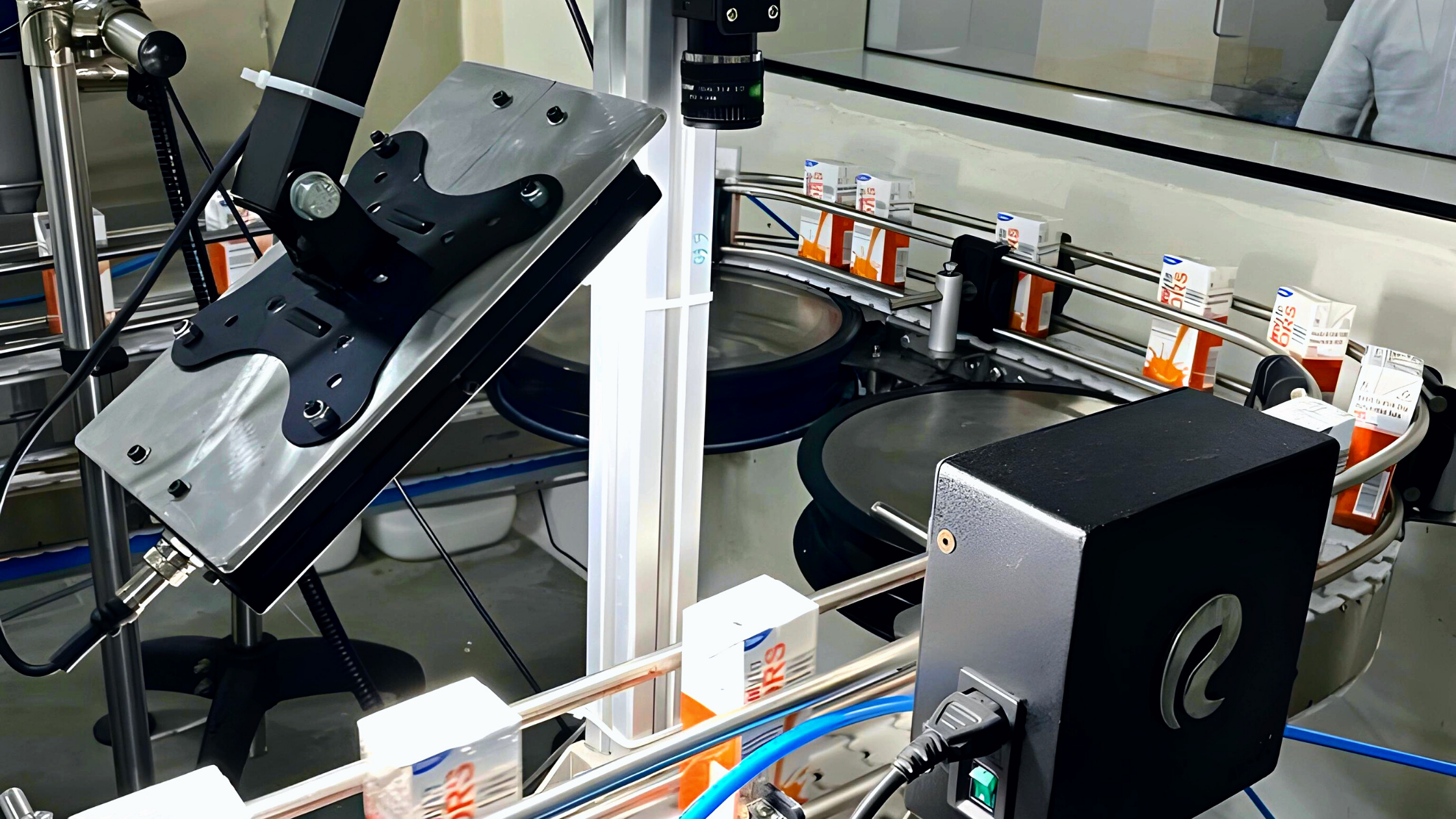

AI-based vision inspection systems can detect unnoticed defects within seconds, which makes them more accurate, consistent, quick, and detailed. Moreover, unlike human fatigue, machine vision systems tirelessly perform 100% accurate inspections improving quality.