Kiara Vision Platform - AI eyes for Industry 4.0

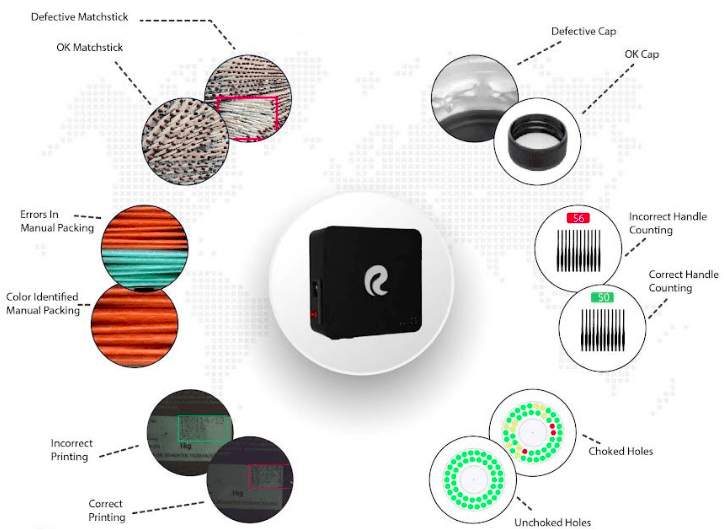

Industries face problems during production, assembly, and printing leading to inferior quality, customer rejections, spoil brand reputation and high costs. Having a constant overview of each and every product and monitoring processes visually is key to ensuring product quality. Kiara is a base platform that delivers unmatched results through AI for camera based inspection, monitoring and counting.

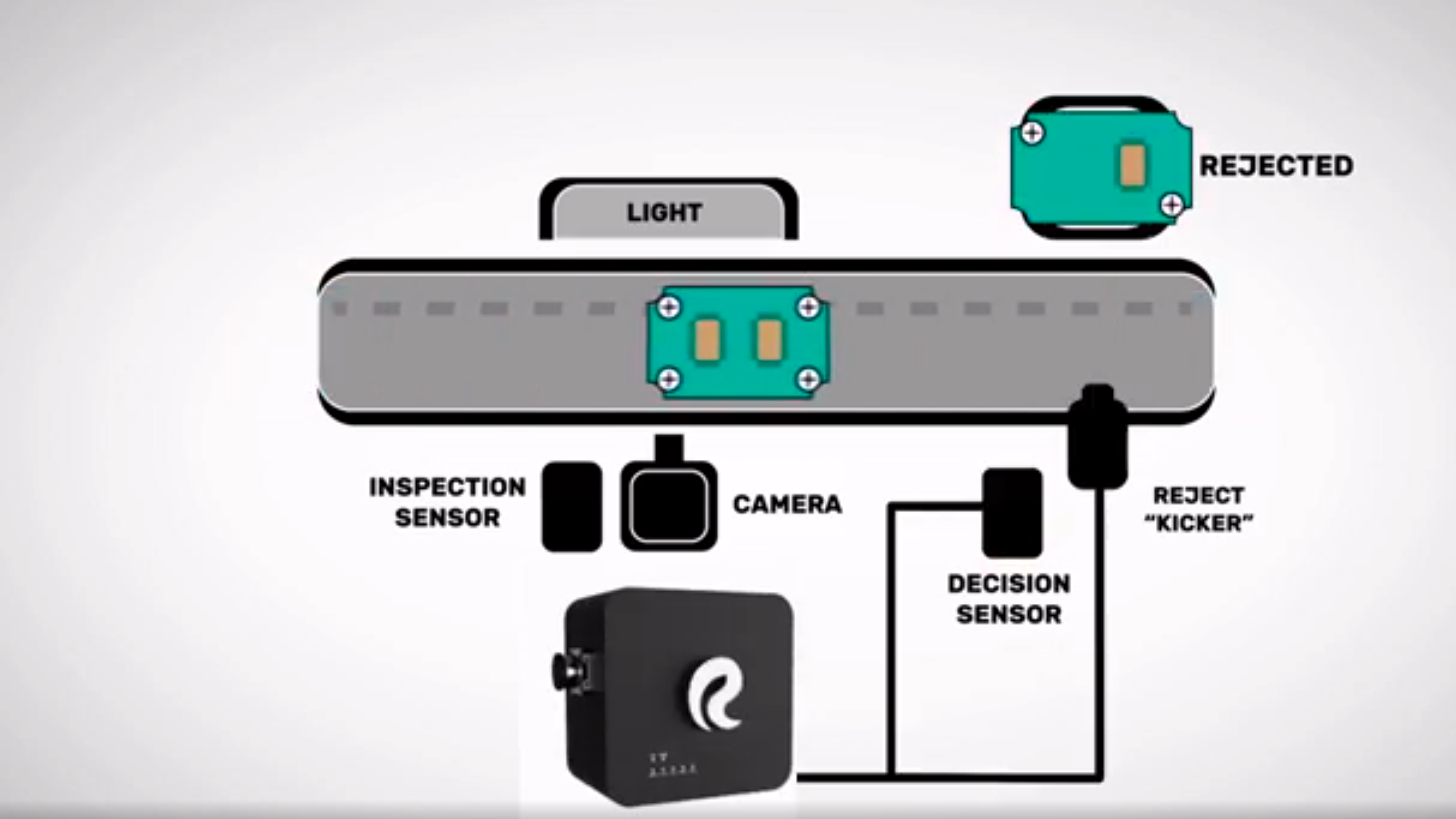

Kiara, an AI-enabled Vision Platform uses the unmatched combination of Machine Learning and High-end Industrial Cameras, to deliver quick and accurate counting, sorting, and defect detection results to various industries, enabling them to match and lead the high standards of Industry 4.0.

70% Waste Reduction

Errors caught early reduce up to 40% wastage in production processes

Save on Costs

Save on Labor costs and expensive reworks. Get 100% inspection!

Ace Quality Audits

Meet your client's quality needs!

Common Industrial Defects

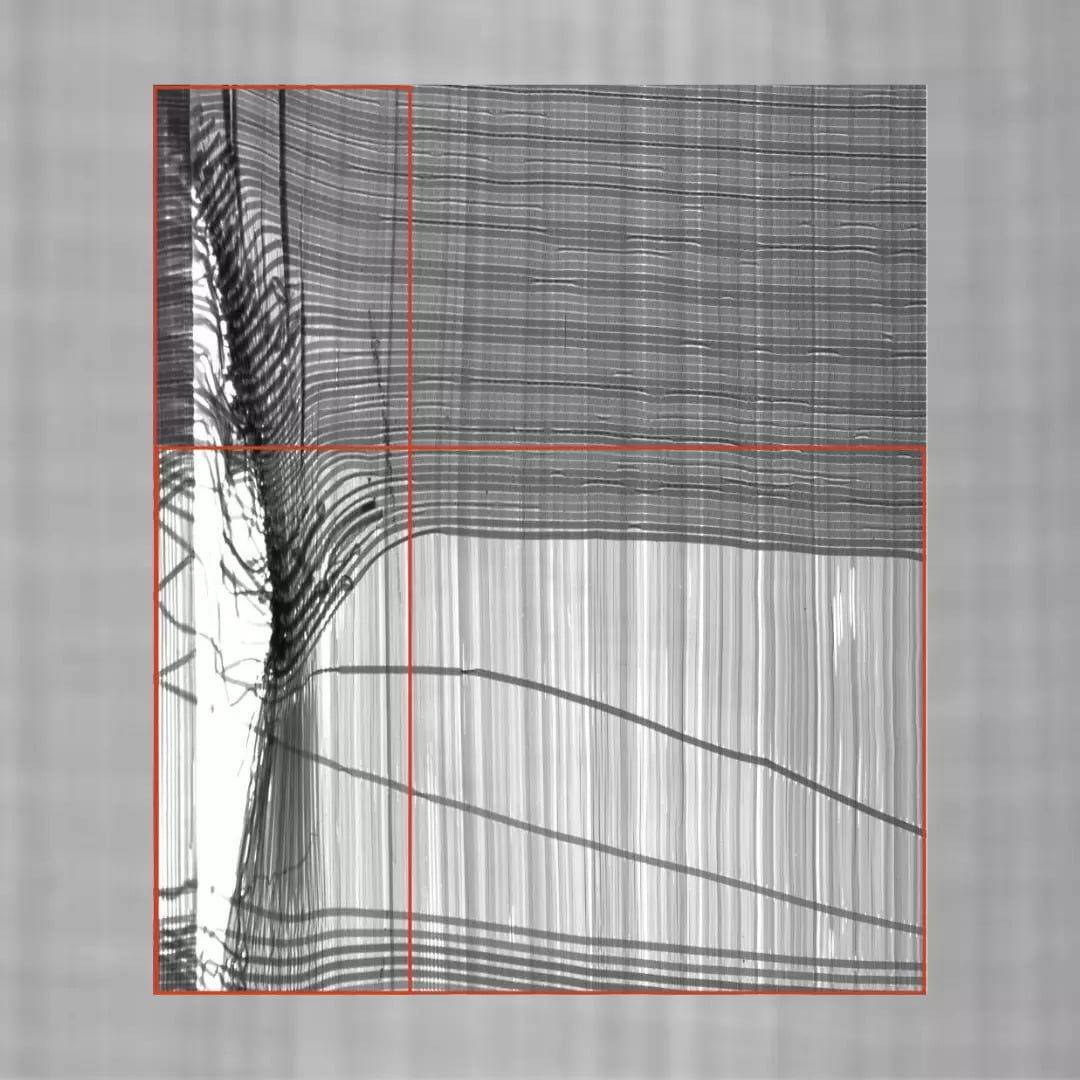

Weaving Defects

Weaving Defects

Manual inspection is an easily accessible method in India, that's why many textile manufacturers opt for this. However, this is a very slow and error-prone method. Industry 4.0 AI Vision Inspection detects each and every small defect at high speeds with up to 100% accuracy.

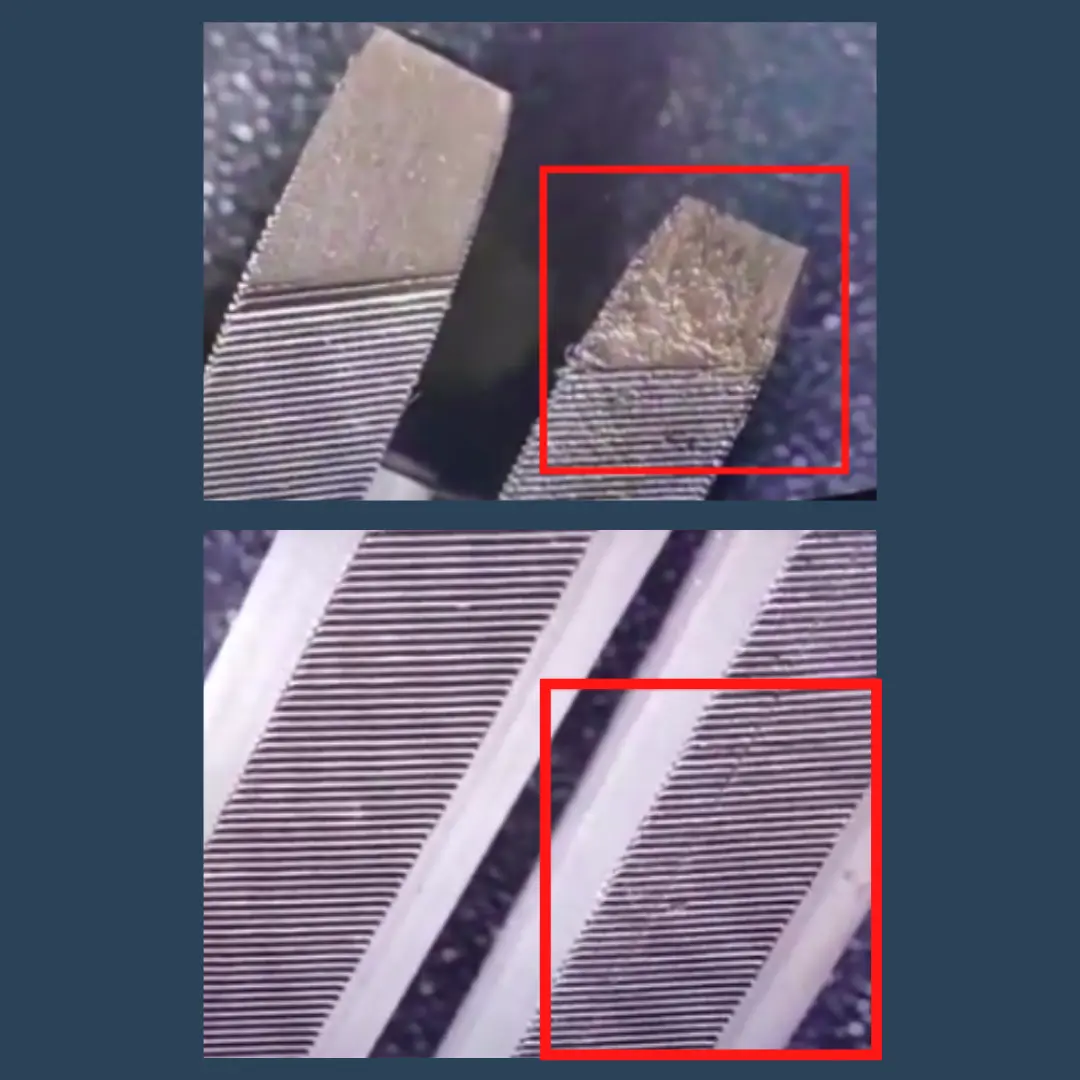

Manufacturing Defects

Manufacturing Defects

Small details in the manufacturing of the metal & automotive parts value a lot for any company's goodwill. Kiara Vision Platform takes into note every small defect at high speed of up to 1000 parts/min with up to 100% accuracy.

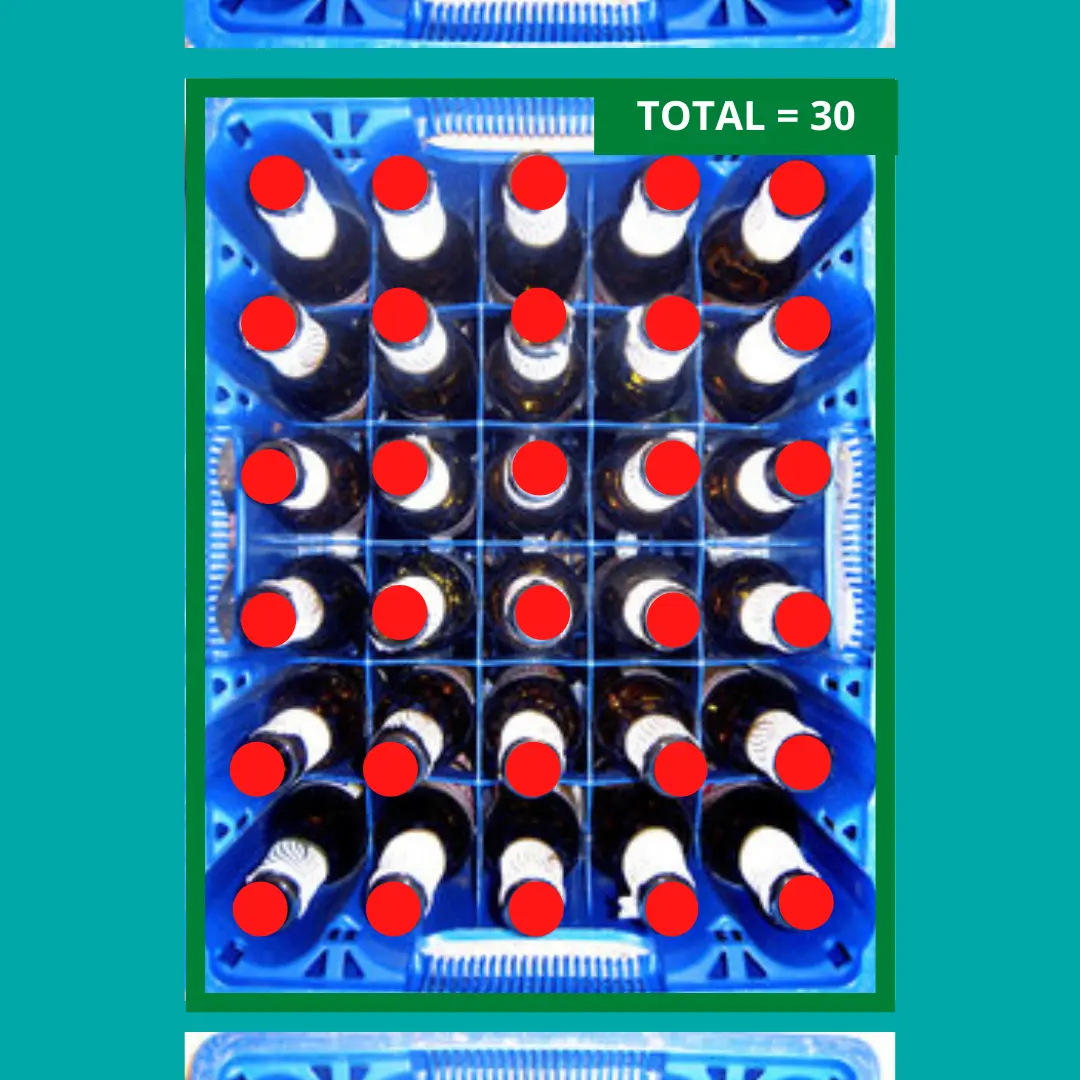

Inaccurate Count

Inaccurate Count

Weight Based Counting consumers a lot of time and still remains inaccurate. KCS is a fast and accurate counting machine to solve this problem.

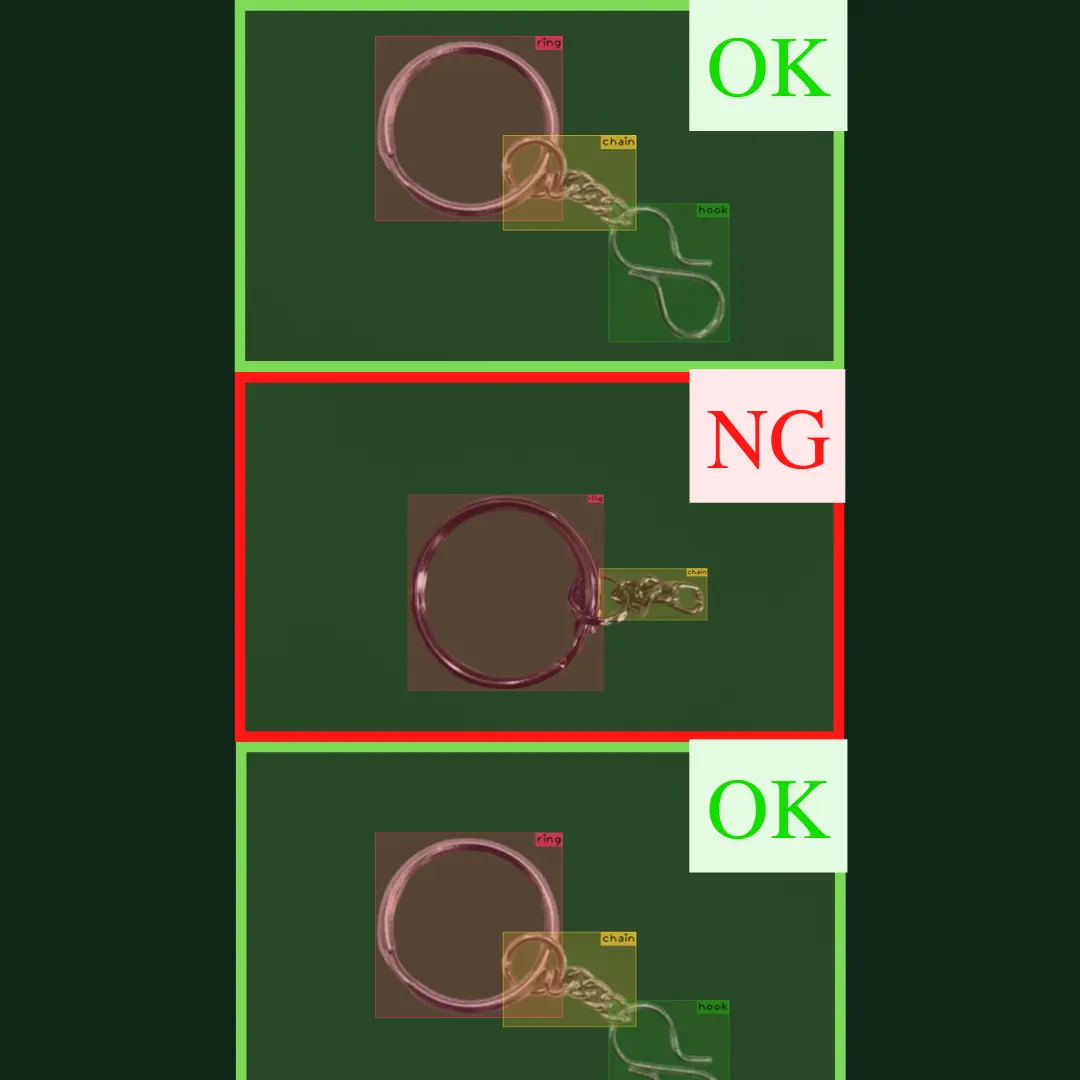

Absence/Presence

Absence/Presence

Automotive and metal products consists of several parts at times. It's necessary to make sure each part is present at the time of inspection to ensure utmost customer satisfaction. Kiara Vision Platform uses AI and Machine learning to identify each different part and ensure up to 100% accuracy at high speeds.

How Kiara Vision

Platform benefits the industry

Kiara is a base platform for all visual analysis tasks! It not only detects the defects, but also rejects or removes the undesirable products from the lot. Ultimately, industries are able to reduce wastage up to 70% and also give a zero defect assurance. Kiara provides an AI software library that continues to learn by examples and quickly understand OK/NG products through a few samples. It is customizable as per the requirement of the application.

Due to the strict protocols implemented by Governments for COVID-19, the number of workers in industries are significantly reduced. Kiara can help cope with the loss due to labor, automating your processes and also ensuring hygiene and no- touch accessibility.