The textile industry is one of the most competitive industries, which makes quality control of utmost importance. Buyers judge the manufacturers based on their ability for delivering superior quality textiles at affordable prices, with efficiency being at its core.

Therefore, manufacturers require strict quality control processes across the entire production line to ensure the final products are of the highest quality. Companies must accurately source the raw materials and check the perfection of the fabric construction. Additionally, they must ensure the final products have zero defects to ensure their sustainability in this highly competitive industry.

The technical advancements in artificial intelligence (AI), machine learning (ML), and deep learning along with processing capabilities improve autonomous decision-making for quality control and optimizing the production process. Machine vision for textile industry uses non-destructive techniques (NDTs) to collect information about various objects without physical intervention.

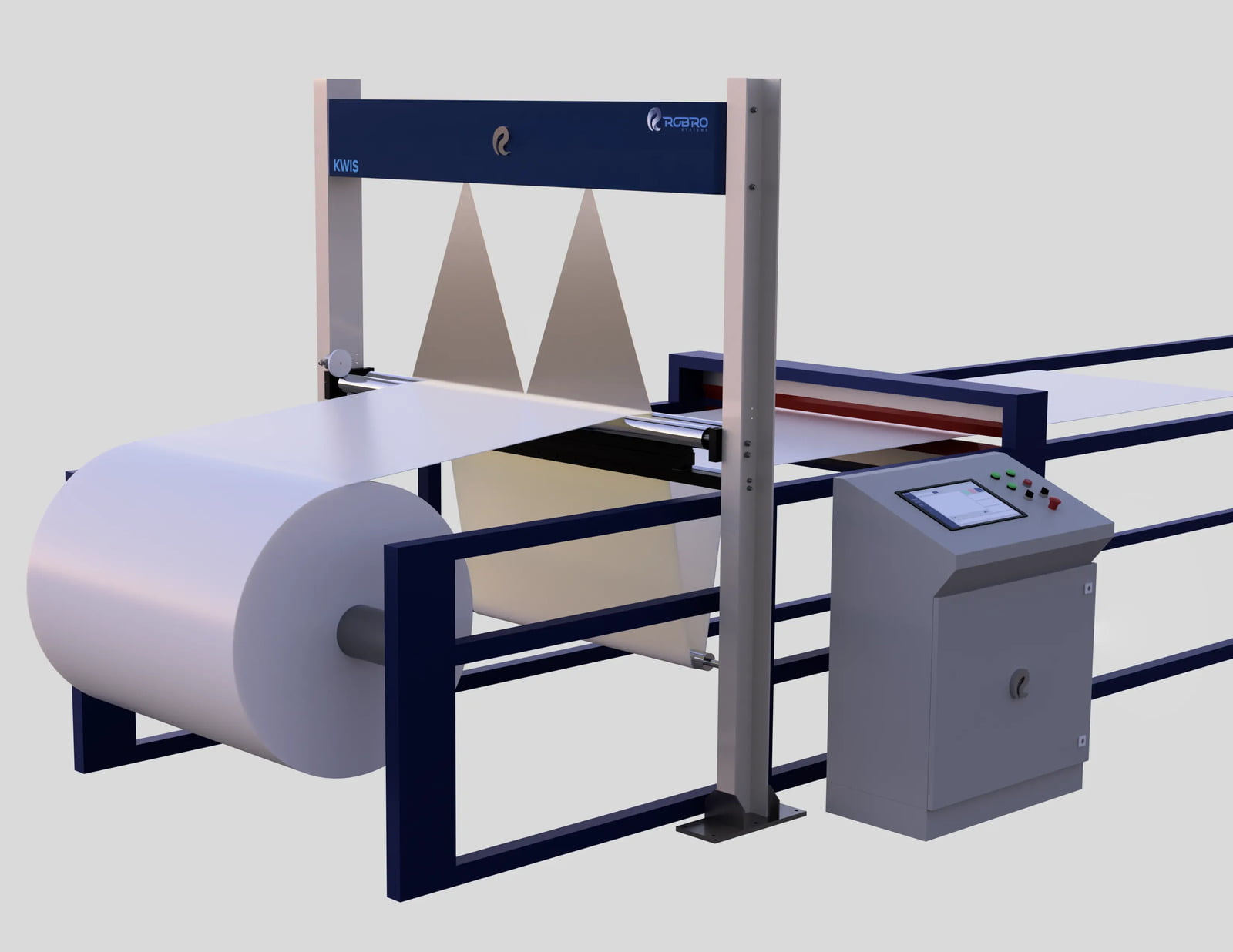

The commonest application is for quality control, where the extracted visual features are used by the operators to make accurate and timely decisions. Automated textile inspection is widely used for replacing human interventions during the entire production process and allows the production of customized fabrics based on consumer requirements.

Textile and Technology Integration

Textiles include various types of materials made from natural and synthetic fibers. To ensure the finished products are defect-free, inspecting the fibers during the production process is important.

This also can result in a 45% to 60% savings on the total expenditure due to wastage or recalling defective products.

The production processes must be based on the end-use as it may include apparel, automotive interiors, insulation, home decor, and more. There is a risk that defects arise due to the textile item, such as when inferior quality materials are selected.

Detecting Structural Defects

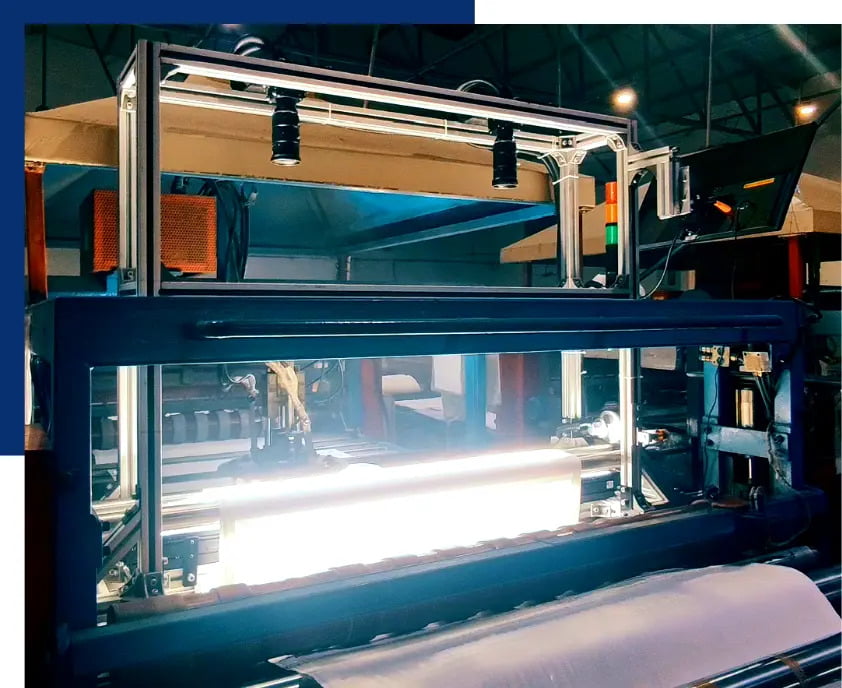

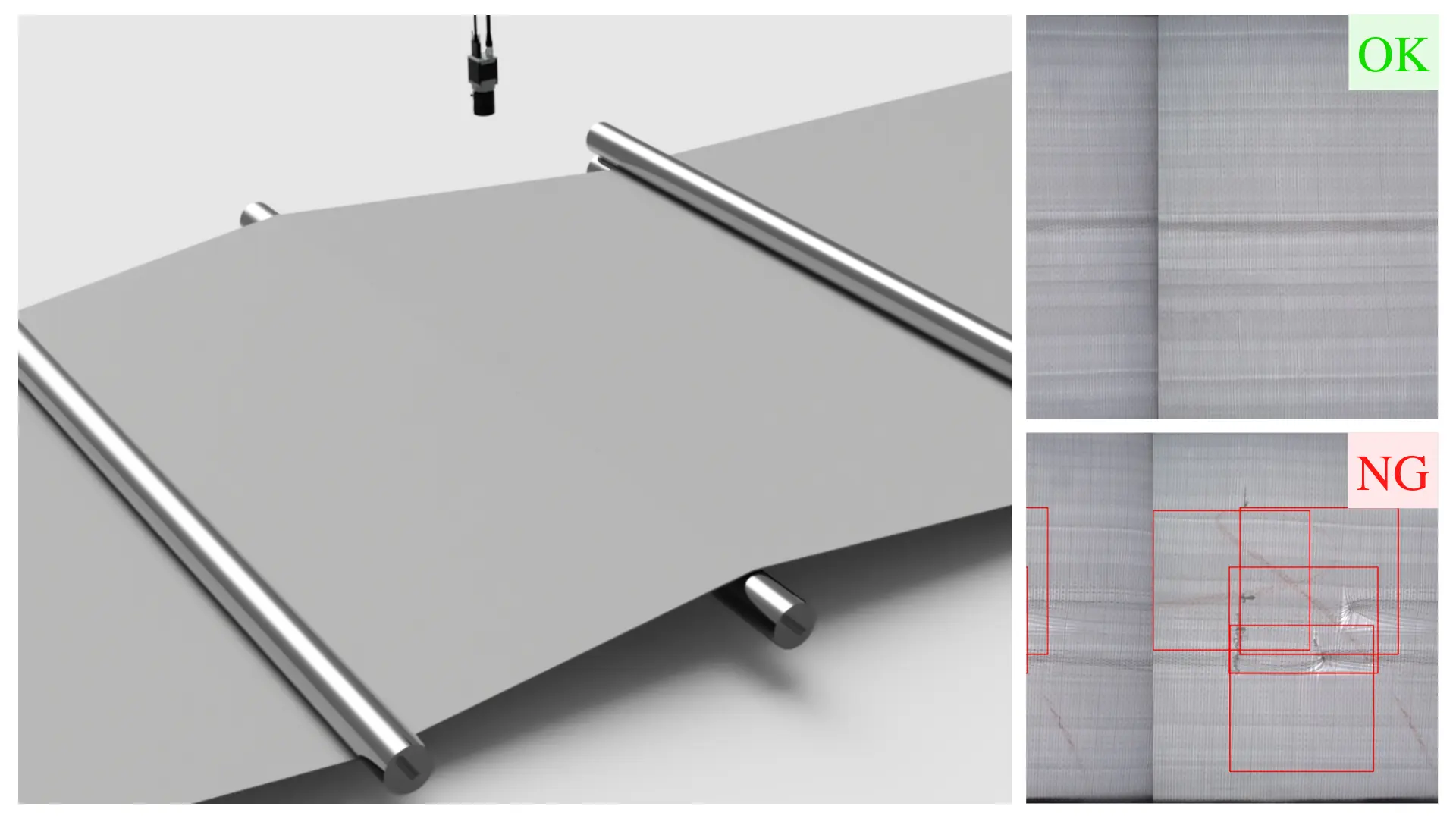

Waste in textile industry can result in huge losses for the manufacturers, which may even impact their sustenance. Computer vision used for reducing such wastage generally involves using high-resolution cameras that can check the quality and provide accurate feedback for making the right production decisions.

The inspection is done with the help of software for image processing. Automated inspection is crucial for defect detection in moving parts at high speeds. The ability of these high-tech systems to work continuously and consistently helps in significantly improving the profitability for the manufacturers.

Line scan cameras are widely used to detect defects in the textile industry. These use single pixel lines for the construction of continuous 2D images as the materials pass through the production line. The cameras can capture superior quality images of various types of materials, which help in detecting any pattern changes without any breaks. Additionally, these cameras can notify operators about any changes in color and texture.

The advanced cameras provide smear-free images at high speeds and come with greater efficiency for processing and lower cost for pixels when compared with conventional area cameras. Timely, continuous, and accurate defect detection using these advanced line cameras ensure any defective material is removed in time before the completion of the entire production process. This helps in reducing textile industry waste as it prevents discarding finished products due to defects.

The textile industry is characterized by repetitive automatic processes and quality-related applications for mass production and lower defects. Machine vision systems capture contextual images of the fabrics and the image quality is improved using filters and advanced techniques enabled by deep learning, ML, and AI. These advanced technologies provide the system with thinking capabilities, which allows the machine vision systems to predict or classify situations that have not been previously experienced.

A significance of textile waste in India occurs during the production process. The wasted material is classified as post-industrial waste or pre-consumer waste. Such wastage not only affects the production efficiency and profitability of the manufacturers, but is harmful to the environment too as it is sent to landfills or burned into ash.

Computer vision is an important tool to reduce textile waste, which helps in minimizing costs while maximizing profitability. These advanced systems allow almost 100% defect-free production, which minimizes waste and promotes ecological sustainability as defects are detected before the products are finished and shipped to the buyers.