Counting small metal parts like screws and bolts is challenging and traditionally is done using weight-based counting systems. But counting by weight can be inaccurate and result in inefficiencies.

Traditional weight-based counting can increase costs and decrease profitability for manufacturers. The weight of each part is not the same, which makes counting by weight inefficient. Often, manufacturers may include additional parts as they do not want to sell lesser number to customers, which can negatively impact their reputation.

The inclusion of additional parts results in extra costs to the company, which in turn reduces their sales and profitability. One way to overcome this limitation is using Vision-based Systems that are compatible with the latest Industry 4.0 technologies and reduce weight-based counting inefficiencies by as much as fifty per cent.

Watch how Artificially Intelligent systems are making the counting jobs easy for small metal part manufacturer

FLEXIBILITY

FLEXIBILITY

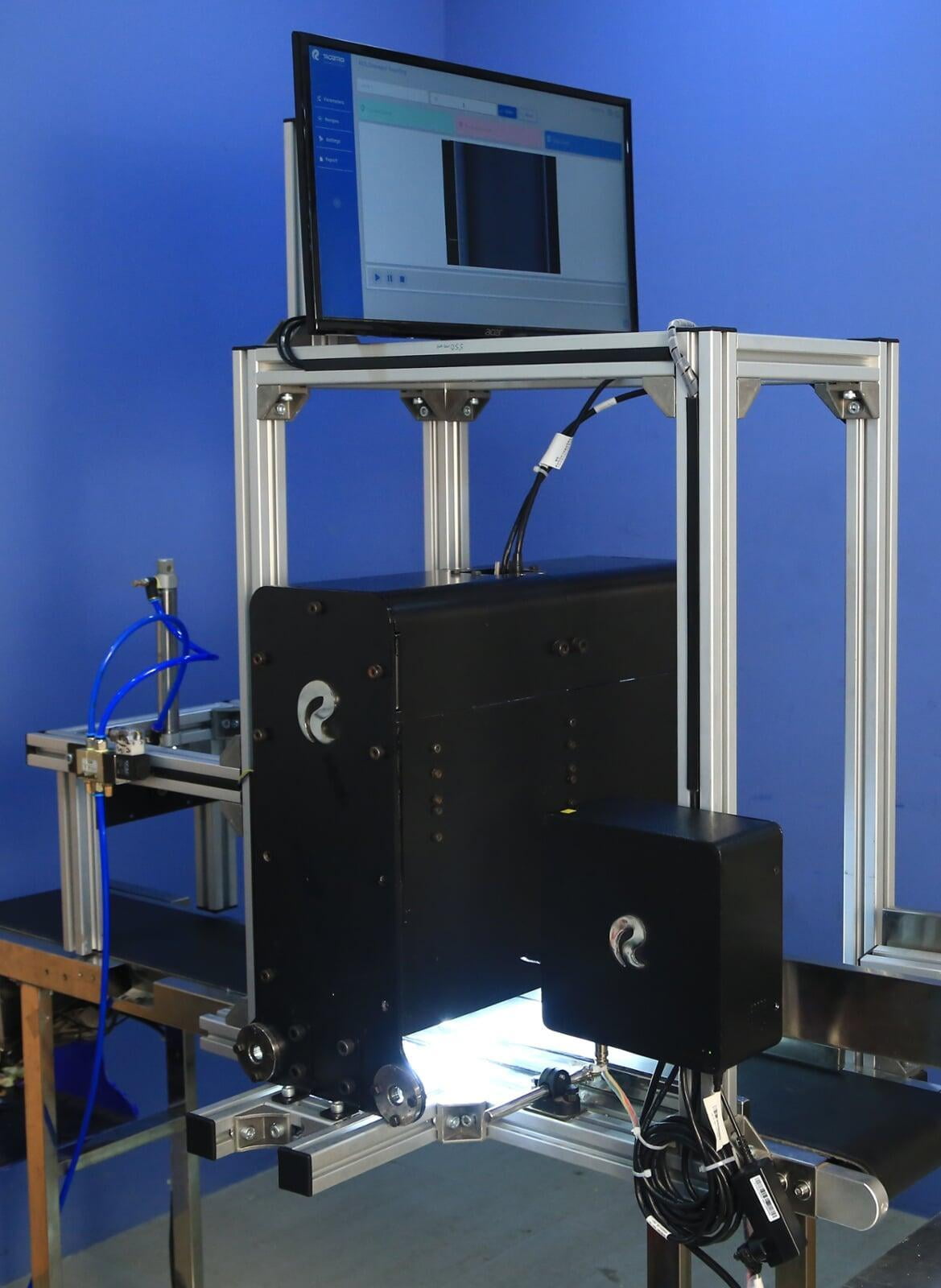

The modern line cameras use advanced technology, which ensures faster counting and near-complete accuracy when compared to existing techniques.

These devices are very versatile and can count the parts in bunches, or while these are in motion along the production line, or from the top. Moreover, these systems can count in different sizes, shapes, and colours of various parts while ensuring counting accuracy.

EFFICIENCY

As already discussed, manual, mechanical, or weight-based counting techniques have several limitations resulting in inaccuracies and inefficiencies. The advanced camera-based counting systems are over 99% accurate and also improve packing efficiency by up to three times. It also eliminates packing extra pieces, which reduces sales and profitability. Another way in which these advanced cameras improve efficiency is by eliminating rejections due to a lesser or more number of items in the package. Therefore, manufacturers ensure there are no rejection costs or extra shipping costs due to an inaccurate number of parts in the package.

QUALITY CONTROL

Globally, regulatory bodies are making quality control regulations more and more stringent. The advanced metal parts counting machine not only ensures an accurate number of items are packed but will also show if any product is damaged, which significantly improves quality control. Enhanced quality control enables manufacturers to deliver accurate products each time, which thereby increases their brand reputation and customer satisfaction. Manufacturing companies can also meet the stringent quality control regulatory norms, which further open higher profit markets across the globe, which in turn can result in a significant rise in sales and profitability.

Automated counting systems are backed by the latest technologies like artificial intelligence, machine learning, and advanced software programs. Therefore, these are highly scalable as per the requirements of every business. Additionally, these systems are intelligent and can learn from repetition, which further improves the efficiency of the manufacturing process.