Automated Error Proofing & Quality Control

Bridging the gap between emerging technologies in machine vision and their adoption in industries of all scale.

Our systems learn by examples and quickly deploy smart eyes to your factory. Go from concept to a working system – within a day.

We aren't satisfied until you are!

What our happiest clients have to say:

What our happiest clients have to say:

Robro Systems' team helped us achieve 100% accurate counting of wood handles that we used to count by weight earlier and had errors up to 20%. Automatic counting has also helped in preventing theft. Counting is 5x faster, and we can see production on our mobiles with their cloud reporting module.

— HOD, Brush Manufacturer

What our happiest clients have to say:

What our happiest clients have to say:

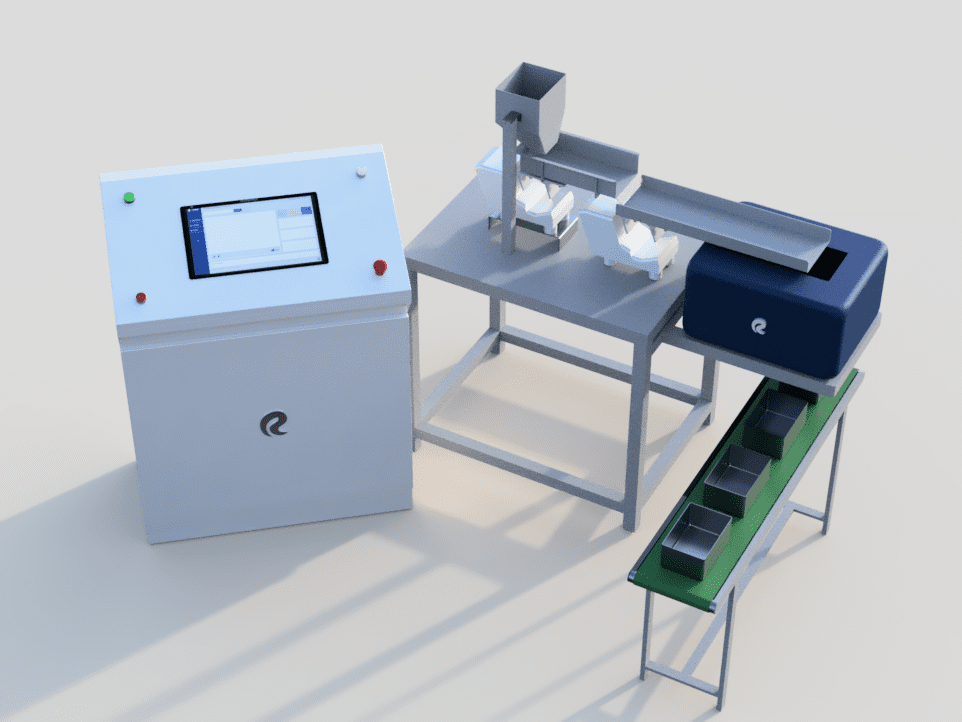

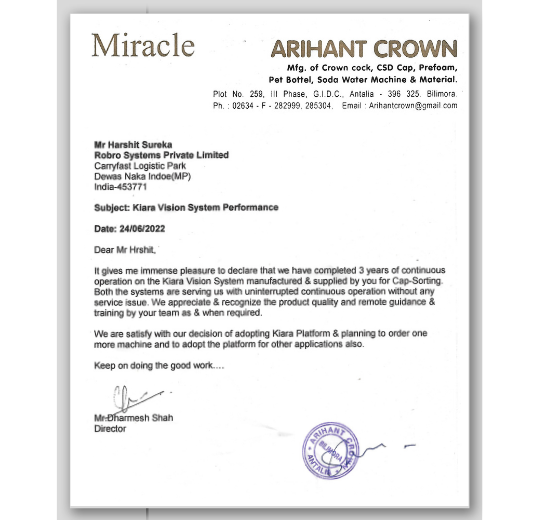

We sort caps based on the type of defects inside them. Manually, it was inefficient and inaccurate. Robro Systems developed a visual sorting machine for us that sorts at >110 caps/min and is >99% accurate. Our customers are delighted and the machine paid off in <1 year. We have ordered another.

- Directors, Arihant Crown

What our happiest clients have to say:

What our happiest clients have to say:

Our Matchsticks Head Inspection System was installed and running in 4 days with all mechanical, electrical and software work. Team is competent and happy to work with them again.

— QC Manager, ITC

Often times, a lot of consultation and discussion needs to go in to make a perfect machine vision solution. We understand the process and have witnessed several pitfalls which lead to unsuccessful projects. We give utmost importance to customer satisfaction at all levels - CXO/ Production Head / Quality Head / Supervisor / Operator. With buy in from all stakeholders and constant support and service, we ensure everyone understands the scope, the solution and the benefits that will come.

OUR CLIENTELE