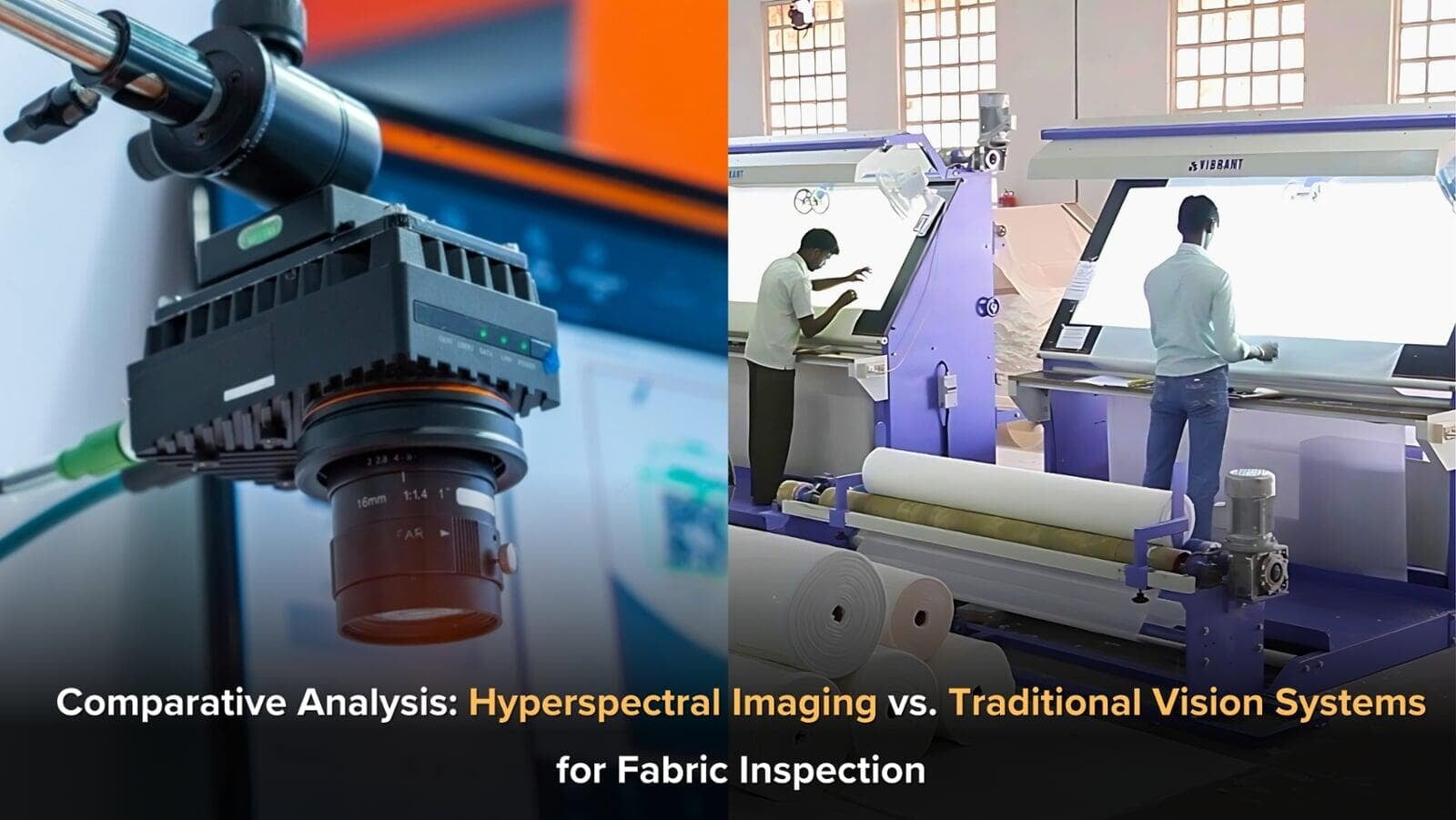

By leveraging AI, deep learning, hyperspectral imaging, and real-time analytics, machine vision systems ensure 99.99% defect detection accuracy, 300% faster production speeds, and significant cost savings. Integrating these systems with Industry 4.0 technologies enables real-time monitoring.